Preparation method of magnetic chitosan-based adsorbent

A chitosan and adsorbent technology, which is applied in the field of water treatment material preparation, can solve problems such as reduced adsorption performance, and achieve the effects of reducing adsorption cost, good performance and improving grafting rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the present embodiment magnetic chitosan-based adsorbent comprises the steps:

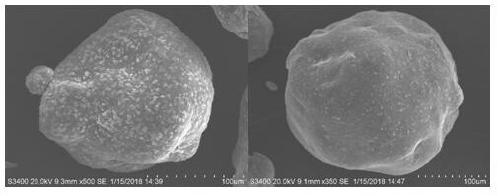

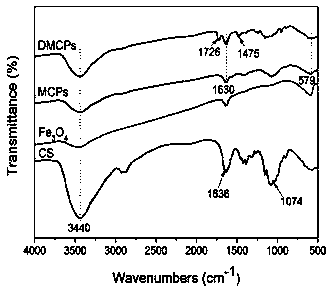

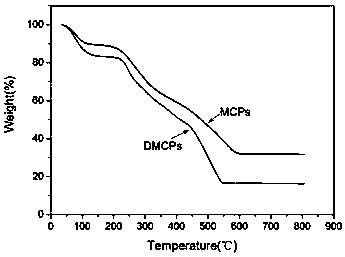

[0033] 1) Fe 3 o 4 - Chitosan particles

[0034] Dissolve 3g of chitosan powder in 20mL of 1% acetic acid solution. Then, 2g Fe 3 o 4 Nanoparticles were added into 5mL distilled water and sonicated for 30 minutes, and its suspension was further mixed with chitosan solution and stirred for 12 hours. Add 200mL cyclohexane and 4mL Span 80 into the three-necked flask, mix and stir for about 1h until the mixture turns into a paste. Chitosan-Fe 3 o 4 The suspension was slowly added to the mixed solution in the three-necked flask to react for 12 hours under vigorous stirring. Then 50% glutaraldehyde (mass 0.93 g) was added into the suspension in the three-necked flask and stirred at 60° C. for 45 min. Under the action of an external magnetic field, the Fe 3 o 4 - Chitosan particles were separated, washed three times with distilled water, and dried under vacuum a...

Embodiment 2

[0065] The difference between the preparation method and the embodiment 1 of the preparation method of the magnetic chitosan-based adsorbent prepared by the present embodiment is: in the step 2), the initiator is the ammonium persulfate of 0.05g / mL, and the add-on is 5mL, methacryloyloxyethyl The add-on of trimethylammonium chloride is 45mL, and other conditions are identical with embodiment 1. After testing, the average degree of grafting of the magnetic chitosan-based adsorbent prepared in this embodiment is 122%.

Embodiment 3

[0067] The difference between the preparation method and Example 1 of the magnetic chitosan-based adsorbent prepared by the present embodiment is: step 2) Initiator is V50 of 0.05g / mL, the addition is 5mL, methacryloyloxyethyltrimethyl The add-on of ammonium chloride is 36mL, and other conditions are identical with embodiment 1. After testing, the average degree of grafting of the magnetic chitosan-based adsorbent prepared in this embodiment is 125%.

[0068] After testing, the adsorbents prepared in Example 2 and Example 3 have good adsorption effects on anionic dye wastewater and heavy metal Cr ion wastewater.

[0069] The assay method of average degree of grafting in the present embodiment is: accurately take by weighing 100mg dry magnetic chitosan-based adsorbent and 200mg acetic acid, dissolve and settle to 100mL with distilled water. Add a certain amount of excessive 0.01mol / L AgNO 3 Standard solution, plus 5mL dibutyl phthalate and 0.16g indicator NH 4 Fe(SO 4 ) 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com