Oil liquid centralized treatment system and treatment method

A technology of centralized treatment and oil, applied in separation methods, chemical instruments and methods, separation of immiscible liquids, etc., can solve the problems of reduced cutting performance, shortened service life, difficult to control, etc. Small error and time cost, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

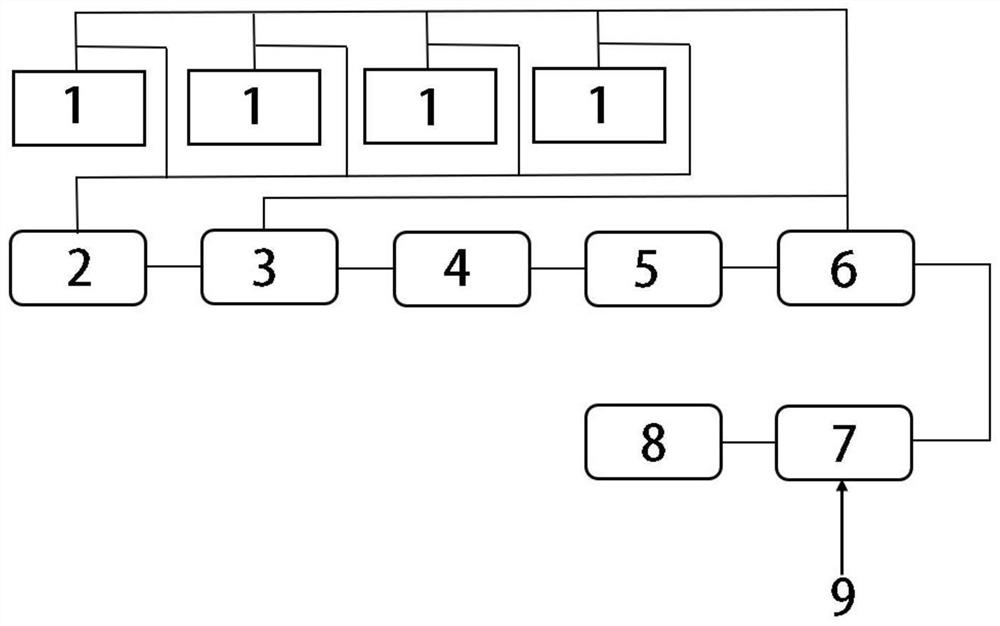

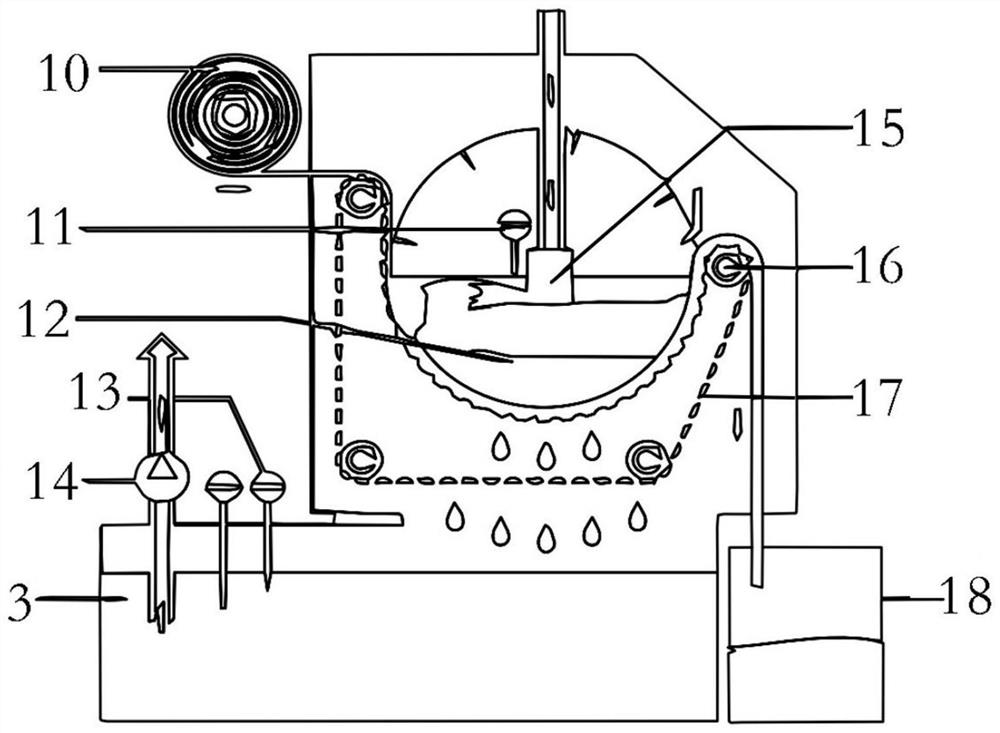

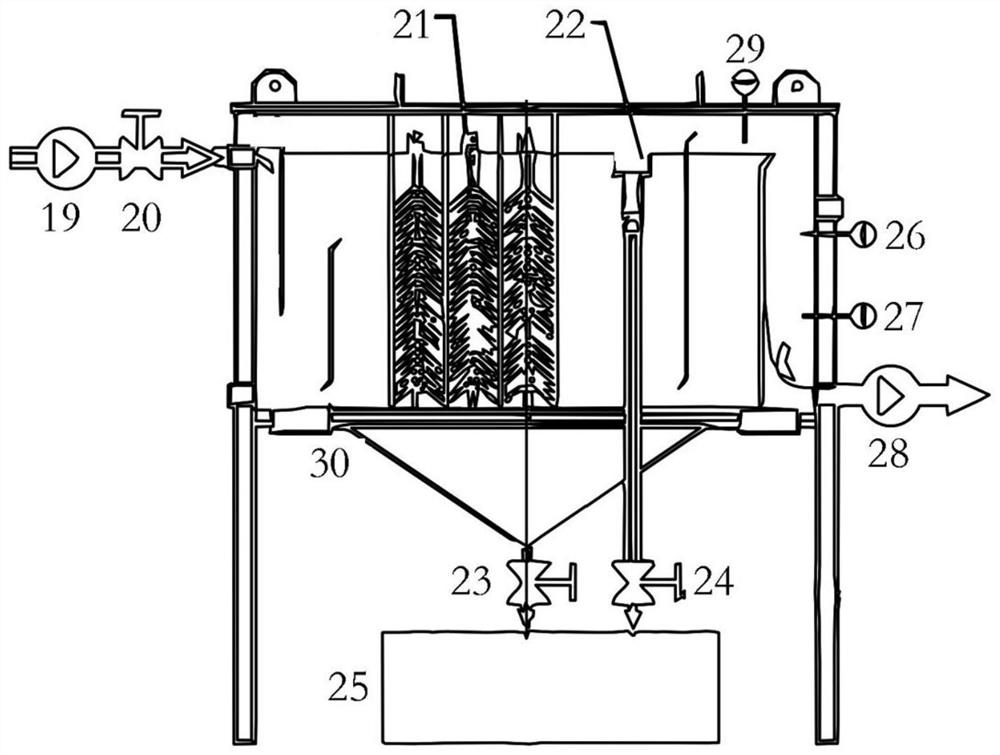

[0030] Such as figure 1 As shown, a centralized oil treatment system includes an oil pumping station, a paper filter device 2, an oil collection box 3, a UV sterilization device 4, a three-phase separation device 5, a clean liquid tank 6 and a liquid supply device , online monitoring device, control system, pipeline and automatic liquid replenishment device; the oil pumping station includes a centrifugal pump, a liquid level control device and a ball valve, and the oil pumping station pumps the oil from the machine tool 1 to the paper belt filter device 2 , the oil enters the oil collection box 3 after being filtered by the paper tape filter device 2, and a liquid level control device is set in the oil collection box 3, and the oil collection box 3 communicates with the UV sterilizing device 4 through a pipeline, and the UV ultraviolet rays The microorganisms in the waste water are sterilized; the UV sterilizing device 4 communicates with the three-phase separation device 5 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com