Preparation method of silicon dioxide coated carbonyl iron material

A technology of silicon dioxide and carbonyl iron, applied in the field of wave absorbing materials, can solve the problems of high cost, uneven distribution of silicon dioxide, low production efficiency of silicon dioxide-wrapped carbonyl iron materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Existing methods for preparing carbonyl iron materials coated with silica, one is by plasma deposition, and the other is prepared by hydrothermal method; however, the silica coated carbonyl iron materials prepared by plasma electron The distribution of silicon is not uniform; while the silicon dioxide-coated iron carbonyl material prepared by the hydrothermal method has low production efficiency and high cost.

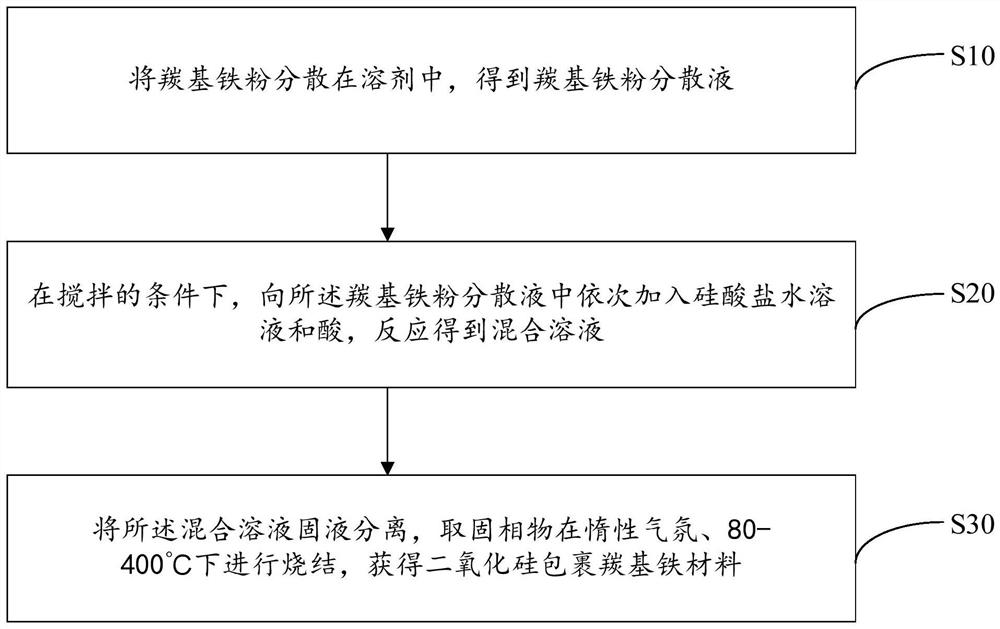

[0031] In view of this, the present invention provides a method for preparing a silica-wrapped carbonyl iron material. The silica-wrapped carbonyl iron material prepared by the preparation method has the advantages of uniform silica wrapping, stable structure and high production efficiency. figure 1 For the schematic flow chart of an embodiment of the preparation method of the silica-wrapped carbonyl iron material provided by the present invention, please refer to figure 1 , in this embodiment, the preparation method of the silica-wrapped carbonyl iron material ...

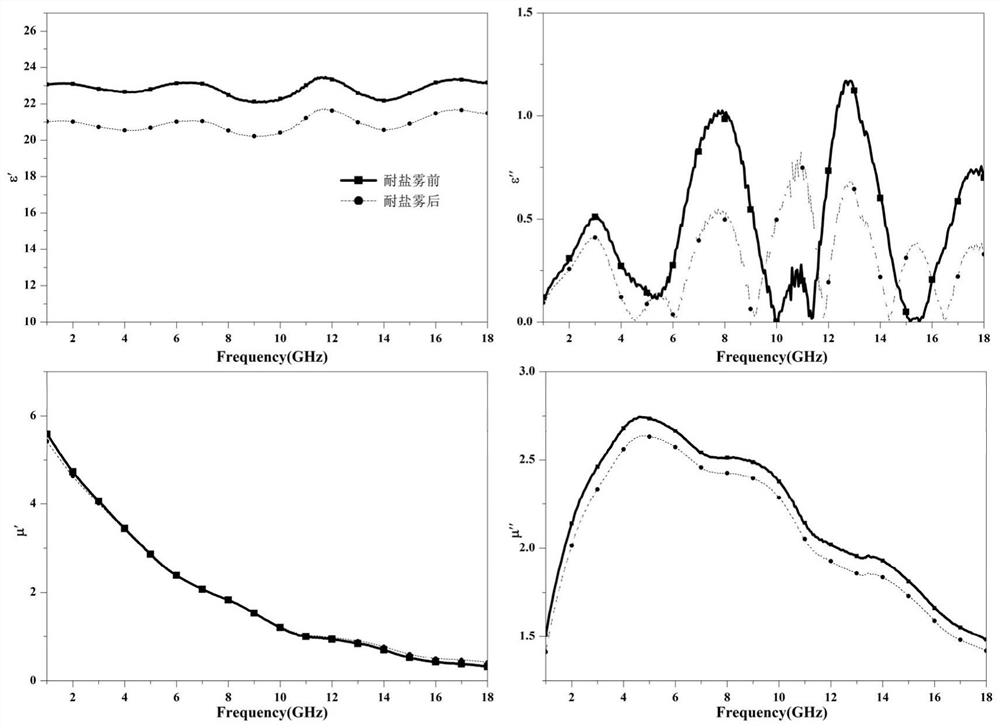

Embodiment 1

[0049] (1) Get 150kg of industrial alcohol and place it in the reactor, get 10kg of carbonyl iron powder and place it in the reactor, and stir at a speed of 45 rpm until the carbonyl iron powder is evenly dispersed in the industrial alcohol to obtain carbonyl Iron powder dispersion;

[0050] (2) Continue to stir at a speed of 45rpm with the stirring speed, add 7kg, a mass percent concentration of 20% sodium silicate solution to the carbonyl iron powder dispersion, stir for 5min, then increase the stirring speed to 200rpm, add 3kg, mass percent The percentage concentration is 30% hydrochloric acid, continue to stir 9h, make it fully react and obtain mixed solution;

[0051] (3) centrifuge the obtained mixed solution, and centrifuge at 3000rpm for 5min, collect the precipitate, use distilled water to clean the precipitate 3 times, then place the cleaned precipitate in an atmosphere furnace, feed argon, and The temperature was heated to 80°C, and after drying for 4 hours, the pr...

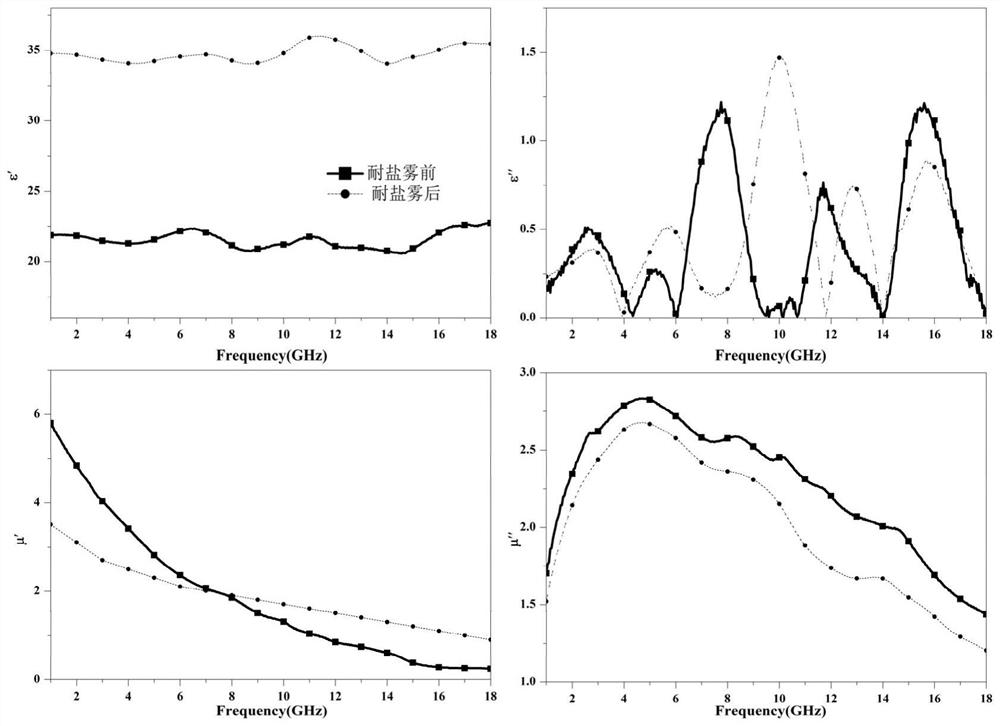

Embodiment 2

[0053] (1) Get 150kg of industrial alcohol and place it in the reactor, get 10kg of carbonyl iron powder and place it in the reactor, and stir at a speed of 47 rpm until the carbonyl iron powder is evenly dispersed in the industrial alcohol to obtain carbonyl Iron powder dispersion;

[0054] (2) Continue to stir at a speed of 47rpm with a stirring speed, add 7kg, a mass percent concentration of 20% sodium silicate solution to the carbonyl iron powder dispersion, stir for 5min, then increase the stirring speed to 200rpm, add 3kg, mass percent The percentage concentration is 30% hydrochloric acid, continue to stir for 5h, make it fully react and obtain mixed solution;

[0055] (3) centrifuge the obtained mixed solution, and centrifuge at 3000rpm for 5min, collect the precipitate, use distilled water to clean the precipitate 3 times, then place the cleaned precipitate in an atmosphere furnace, feed argon, and The temperature was heated to 80°C, and after drying for 4 hours, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com