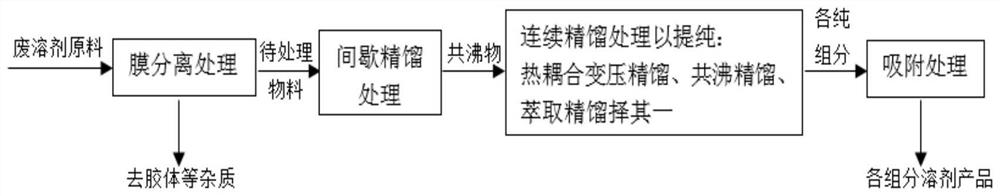

Method for treating waste electronic solvent containing water, propylene glycol monomethyl ether and cyclopentanone

A technology of propylene glycol methyl ether and a treatment method, which is applied in the field of waste solvent recovery, can solve the problems of effective separation and recovery of difficult waste electronic solvents, achieve great economic and social benefits, simplify the operation process, and achieve high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] 700 g of waste electronic solvent raw materials (containing water α, propylene glycol methyl ether β, and cyclopentanone γ) were treated by membrane separation to obtain a total material weight of 668 g. The appearance of the material was black. The components in the test material and the percentages of each component are shown in Table 1.

[0071] Table 1 The components of waste electronic solvent raw materials obtained after membrane separation treatment

[0072]

[0073] (Note: Other components in the table are divided into easily separated dimethyl sulfoxide DMSO, propylene glycol methyl ether acetate PMA and other heavy components).

[0074] For the processing method of this waste electronic solvent raw material, concrete steps are as follows:

[0075] (1) The waste electronic solvent is subjected to membrane separation treatment - tubular microfiltration membrane (TMF), the filter pore size is 0.2 microns, and suspended solids and large molecular weight colloid...

Embodiment 2

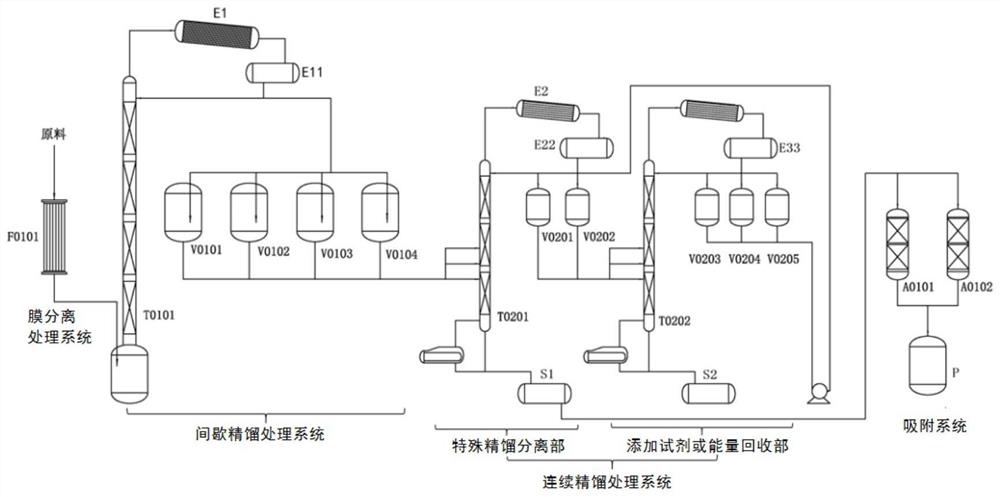

[0082] The A product obtained in Example 1 was enriched in one of the collection tanks through the batch rectification treatment system (600g of A product was obtained after being processed by multiple batches of raw materials, containing α43.64wt%, containing γ56.36wt%) Enter the subsequent continuous rectification treatment system for rectification treatment. The continuous rectification treatment system is composed of two rectification fraction systems: a special rectification separation part and a reagent addition or energy recovery part ( Figure 4 ), the A product is first entered into the second rectification tower T0201 of the special rectification separation section for continuous rectification (feeding at a rate of 120g / h), the second rectification tower T0201 has 20 theoretical plates, and adopts Atmospheric rectification (1 standard atmospheric pressure), reflux ratio is controlled at 4~6, adds entrainer toluene (400g) on the first tray plate of the second rectifi...

Embodiment 3

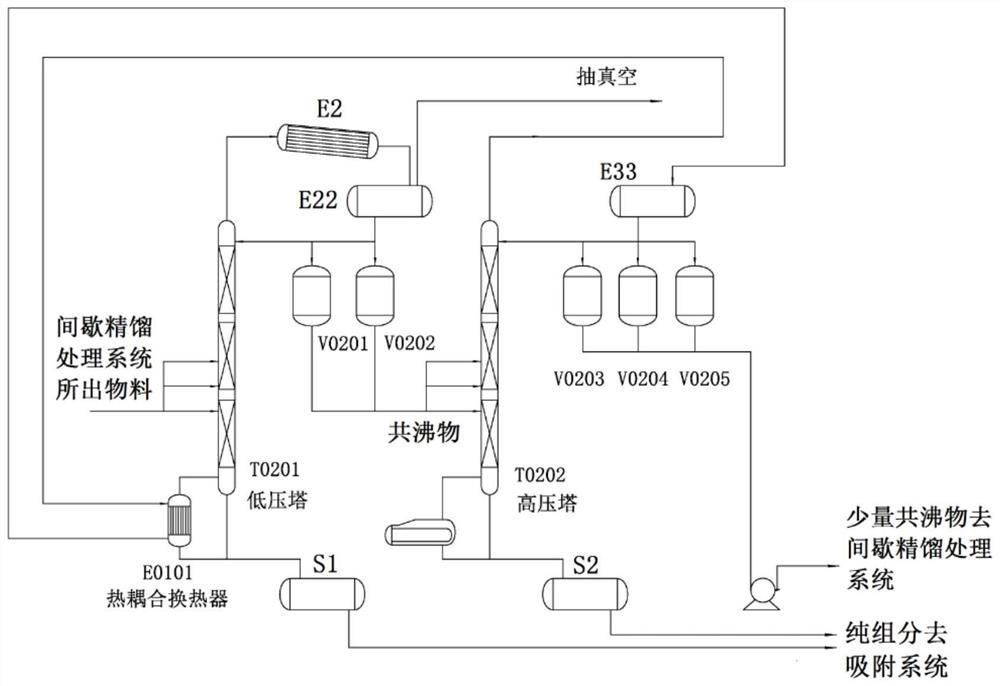

[0085] The C product obtained by enriching in one of the collection tanks through the batch rectification treatment system in Example 1 (enrichment obtained after processing multiple batches of raw materials to obtain 600g C product, containing β 72.4wt% and containing γ 27.6wt% ) into the follow-up continuous rectification treatment system for rectification treatment. The continuous rectification treatment system consists of two rectification fraction systems: a special rectification separation part and a reagent addition or energy recovery part ( image 3 ), the C product is first entered into the second rectification tower T0201 (low pressure tower) of the special rectification separation section for continuous rectification (feeding at a rate of 120g / h), the second rectification tower T0201 theoretical plate number 20 pieces, the rectification pressure is controlled to be 8kPa, the reflux ratio is 4, and the top temperature is 45°C. After being condensed by the top condense...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com