High-heat-resistance modified ABS (Acrylonitrile Butadiene Styrene) material with strong adhesion with PUR (Polyurethane) and preparation method thereof

An ABS material and high heat-resistant technology, which is applied in the field of high heat-resistant polyurethane bonding ABS material and its preparation, can solve the problems of not meeting high strength requirements, being easily damaged, and affecting the dimensional stability of parts, so as to promote Effects of compatibility, strong bondability, high-efficiency dyne value, and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

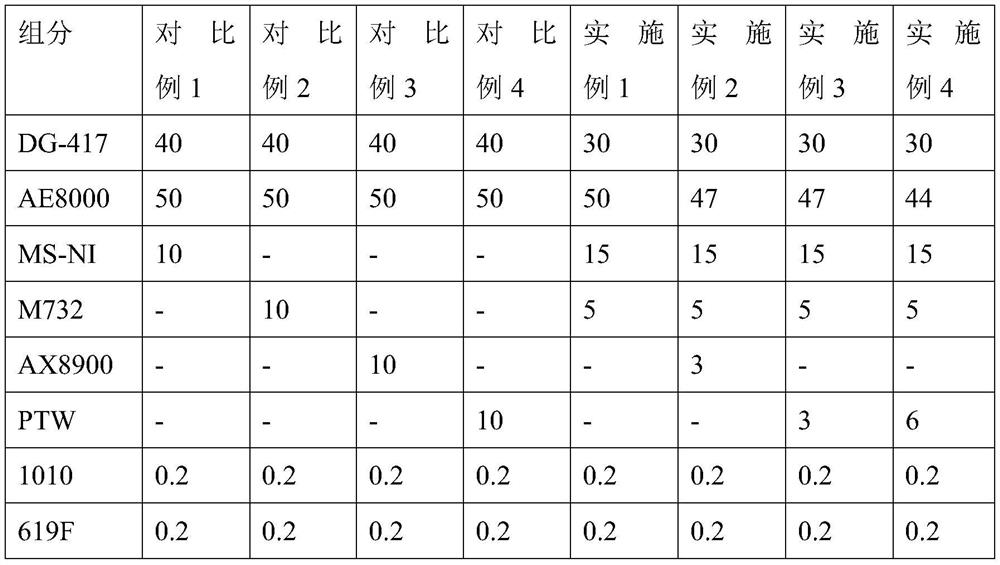

[0029] Weigh 30 parts of ABS DG-417, 50 parts of ABS AE8000, 15 parts of MS-NI, 5 parts of MBS-M732, 0.2 parts of each of antioxidant 1010 and 619F, pre-mix in a mixer for 10-15 minutes, and then The mixture is poured into the main feeding port of the twin-screw extruder, the extrusion temperature is adjusted to 220-240°C, the screw speed is 450-600rpm, the extrusion is cooled by a water tank, and the pellets are granulated by a pelletizer.

Embodiment 2-4

[0031] ABS resin examples 2-4 were prepared according to the method of Example 1, and the specific formulations are shown in Table 1.

[0032]

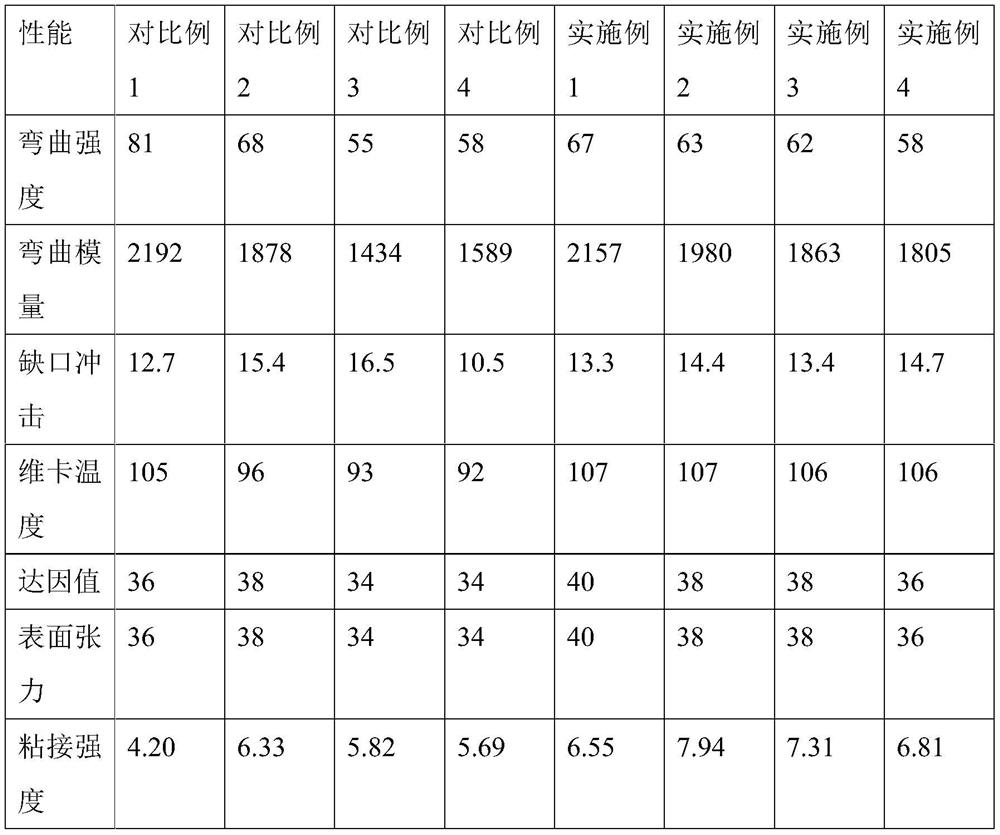

[0033] Extrude the particles in the comparative examples and examples, bake them at 90°C / 4h, and inject them into 80*10*4mm strips. In the performance test results, the flexural strength and modulus adopt the ISO 178 standard; the notched impact strength adopts the ISO 179 standard / 1eA standard; Vicat softening temperature adopts ISO306-B50 test method; dyne value adopts A.Shine dyne value pen, draw a stroke on the smooth sample plate with the pen, if the liquid does not shrink within three seconds, it reaches the selected dyne , otherwise not reached; surface tension using optical contact angle measurement method.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com