A kind of method of dry cleaning germanium wafer

A dry cleaning, wafer technology, applied in cleaning methods and utensils, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of difficult surface state of germanium, application limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

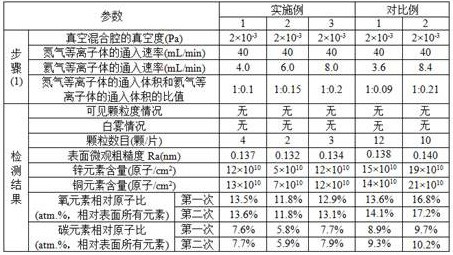

Embodiment 1~3 and comparative example 1~2

[0050] Example 1 provides a method of dry cleaning germanium wafers, comprising the following steps:

[0051] (1) The degree of vacuum is 2×10 -3 The vacuum mixing chamber of Pa is respectively injected into the nitrogen plasma and helium plasma to obtain the mixed plasma; wherein the penetration rate of the nitrogen plasma into the vacuum mixing chamber is 40mL / min, the passage rate of helium plasma into the vacuum mixing chamber is 4.0mL / min, and the ratio of the penetration volume of the nitrogen plasma into the vacuum mixing chamber and the volume of the helium plasma into the vacuum mixing chamber is 1:0.1;

[0052] (2) Place the germanium wafer in a vacuum of 2×10 -3 Pa in the vacuum cleaning chamber and heated up to 300 ° C; after that, to the vacuum cleaning chamber into the mixed plasma, the mixed plasma to clean the germanium wafer and passivate the surface of the germanium wafer; the mixed plasma into the vacuum cleaning chamber penetration rate of 75mL / min, the acces...

Embodiment 4~5 and comparative example 3~5

[0063] Compared with Example 2, the difference between Examples 4 to 5 and the proportional ratio 3 to 5 is that the temperature of the vacuum cleaning chamber in step (2) is different. Wherein, the specific parameters of step (2) in the proportion of 3 to 5 and the polishing surface of the germanium wafer are shown in Table 2.

[0064] Table 2 Embodiment 4 to 5 and the specific parameters of the proportional step (2) of the ratio 3 to 5 and the detection results of the polished surface of the germanium wafer

[0065]

[0066] Combined with Table 1 and Table 2, it can be seen that the present application by controlling the temperature of the vacuum cleaning chamber in step (2) to affect the cleaning effect of the polishing surface of the germanium wafer, and the temperature of the vacuum cleaning chamber is controlled in the range of 280 ~ 320 ° C, the cleaning effect of the polishing surface of the germanium wafer can be improved; wherein the temperature of the vacuum cleaning ...

Embodiment 6~10

[0068] Compared with Example 2, the difference between Examples 6 to 10 is that the mixed plasma is passed into the vacuum cleaning chamber in step (2) at a different rate. Wherein, the specific parameters of step (2) in Example 6 to 10 and the detection results of the polishing surface of the germanium wafer are shown in Table 3.

[0069] Table 3 The specific parameters of step (2) in Example 6 to 10 and the detection results of the polishing surface of the germanium wafer

[0070]

[0071] As can be seen from the combination of Table 1 and Table 3, the present application by mixing plasma into the vacuum cleaning chamber in step (2) to affect the cleaning effect of the polishing surface of the germanium wafer; wherein the mixed plasma into the vacuum cleaning chamber in step (2) is controlled at a rate of 70 to 80 mL / min, the cleaning effect of the polishing surface of the germanium wafer is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com