Patents

Literature

38 results about "Helium plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

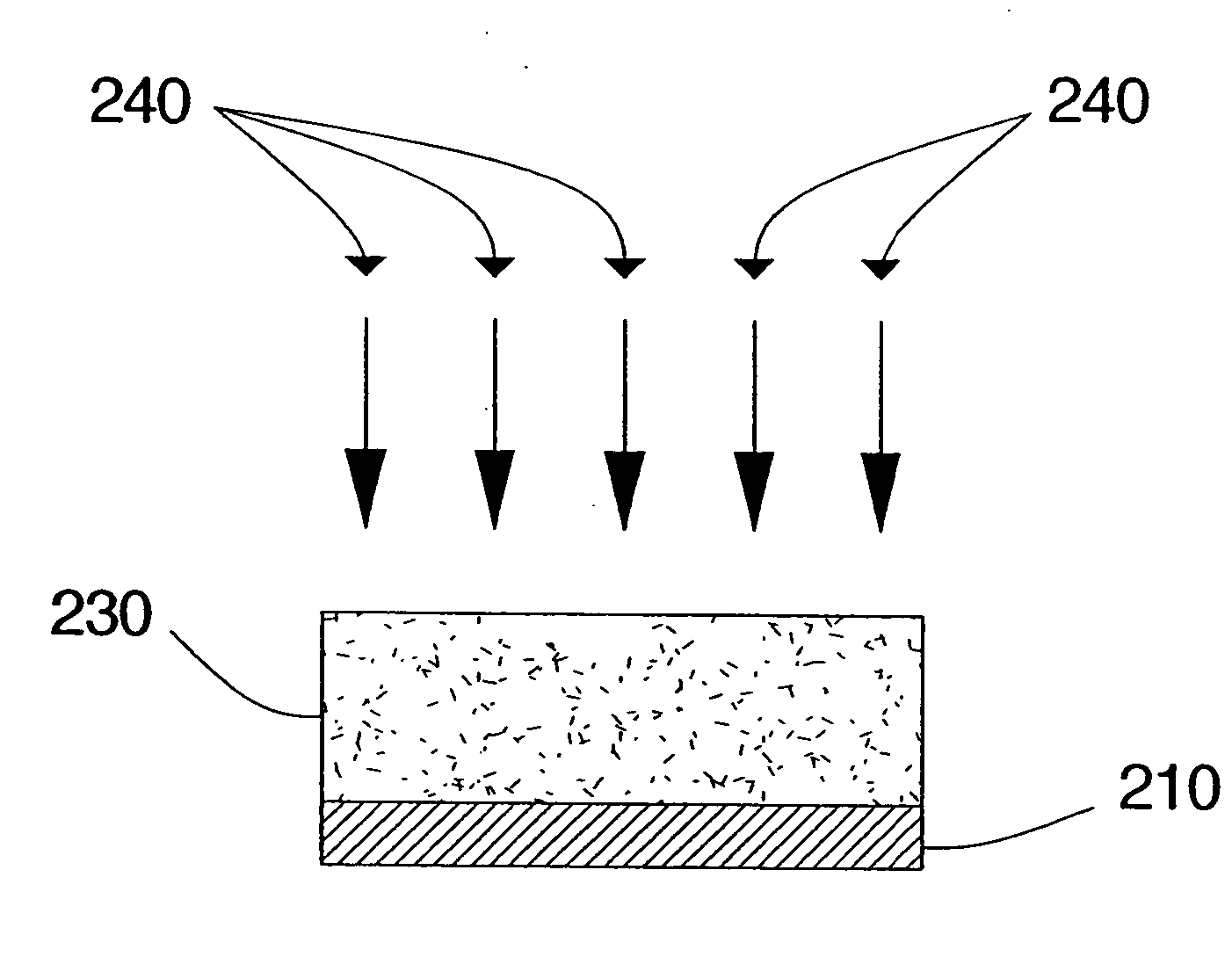

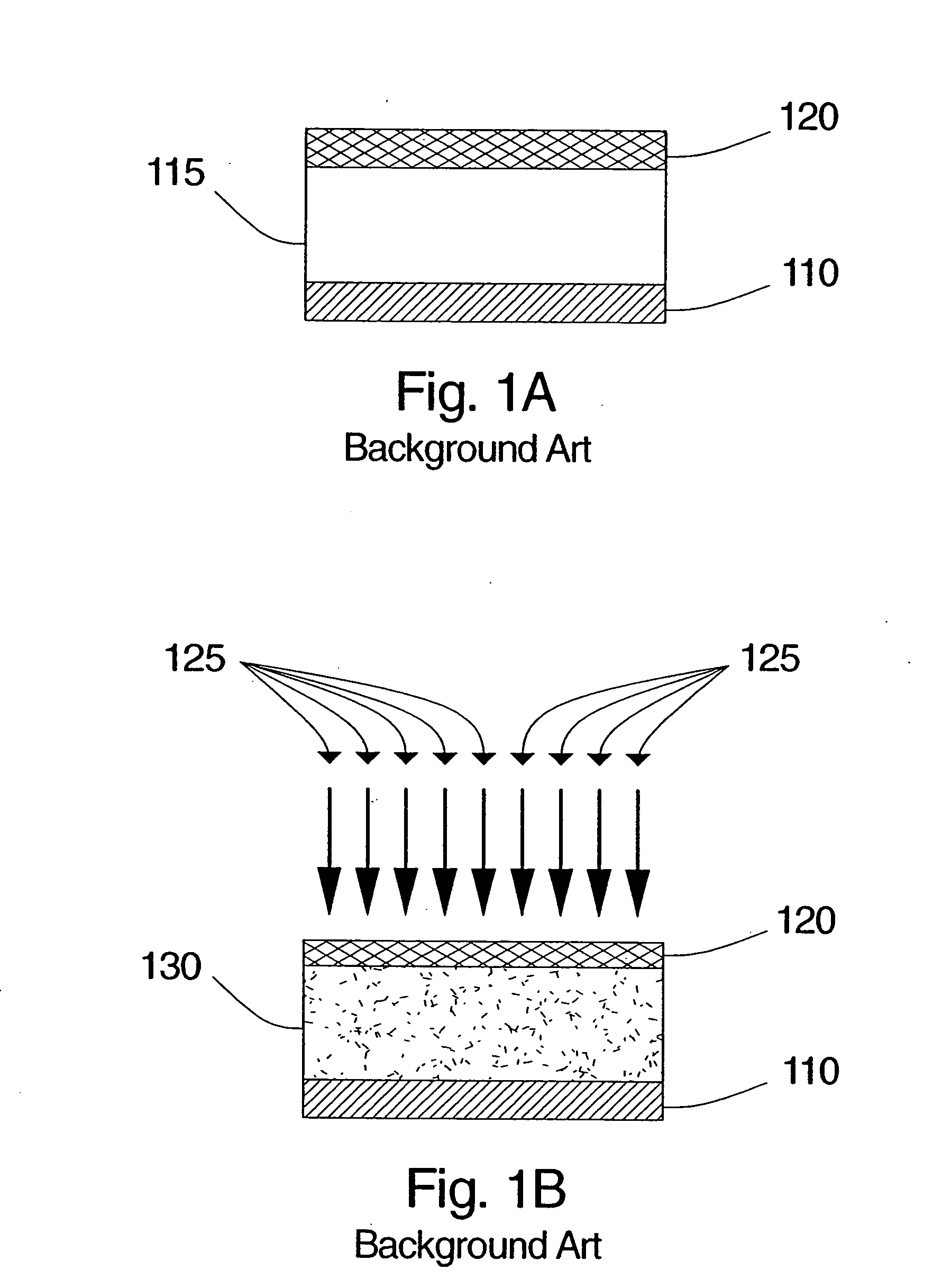

Low temperature formation of high quality silicon oxide films in semiconductor device manufacturing

ActiveUS9847221B1Relieve pressureReduce film stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricDevice material

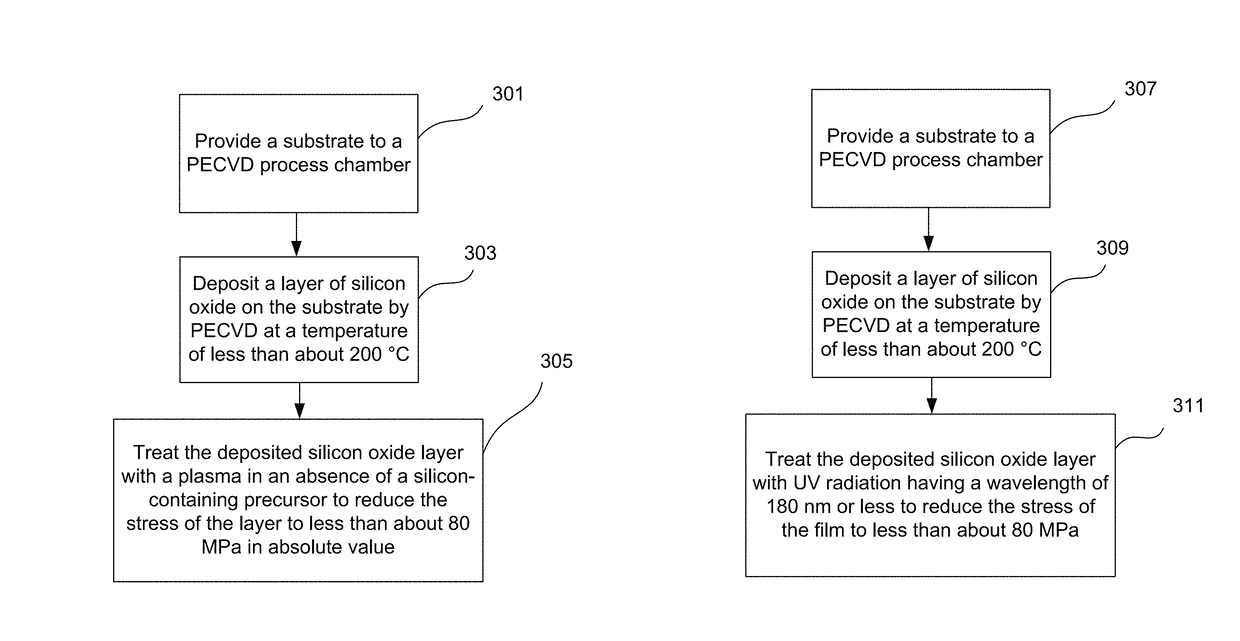

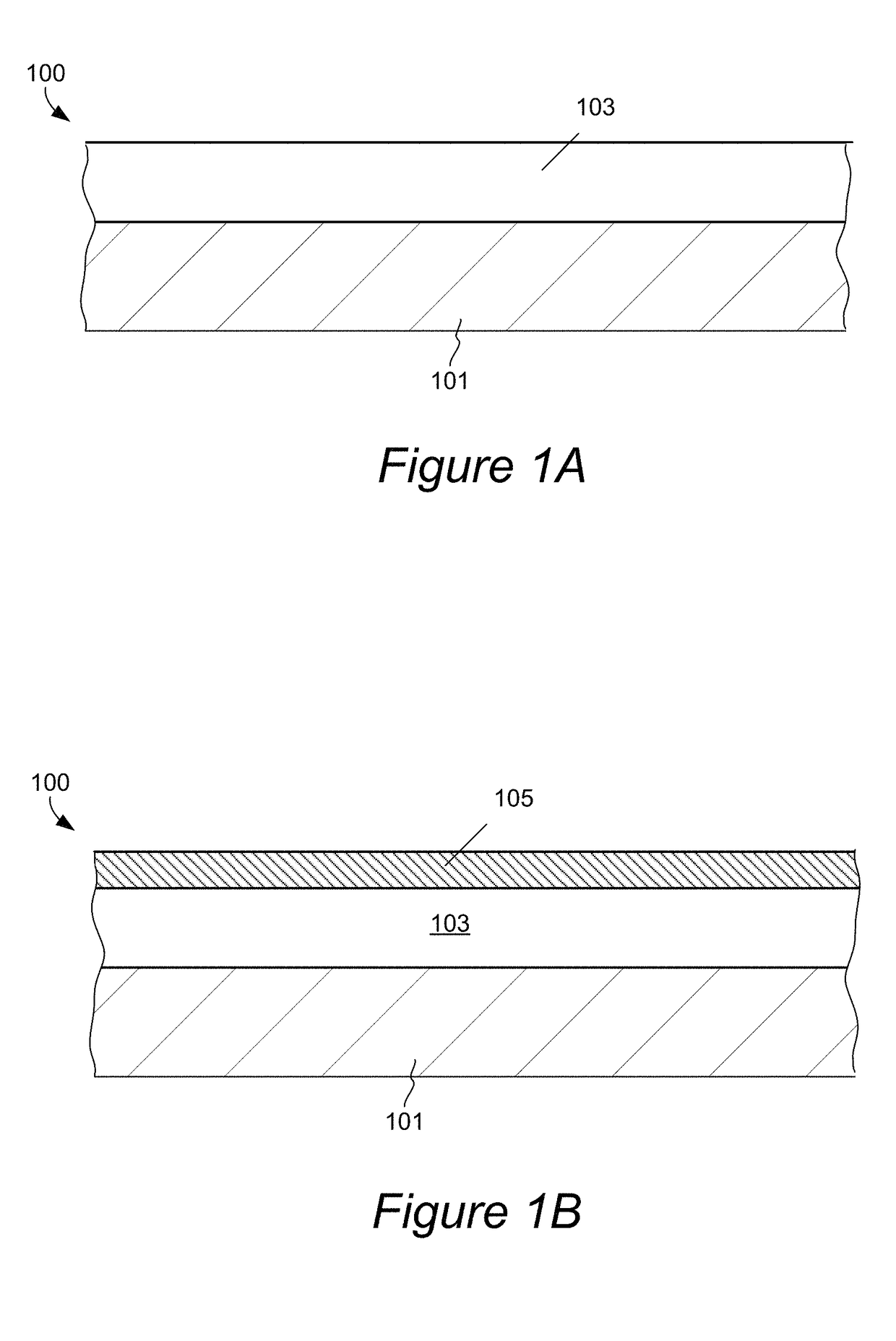

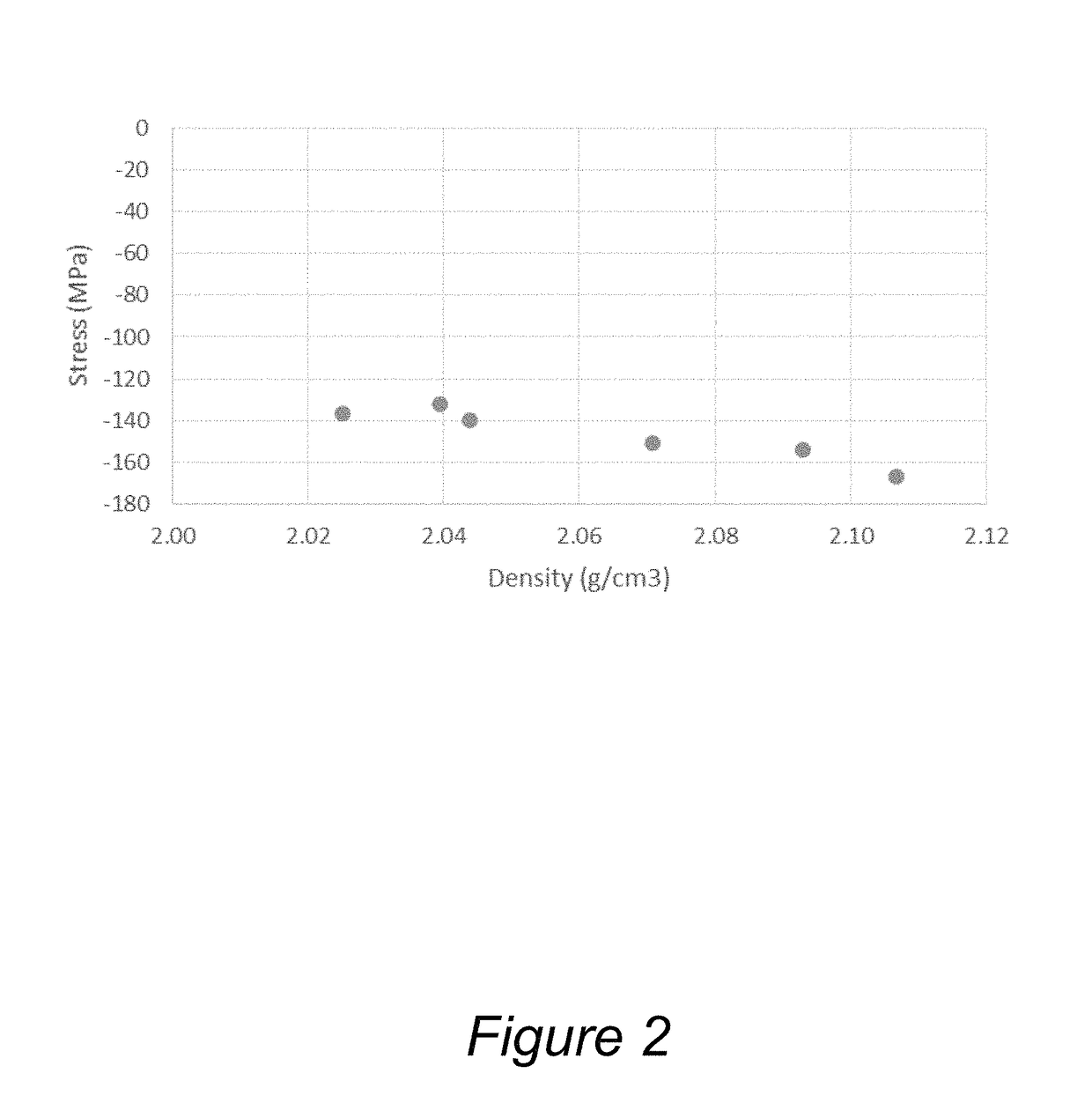

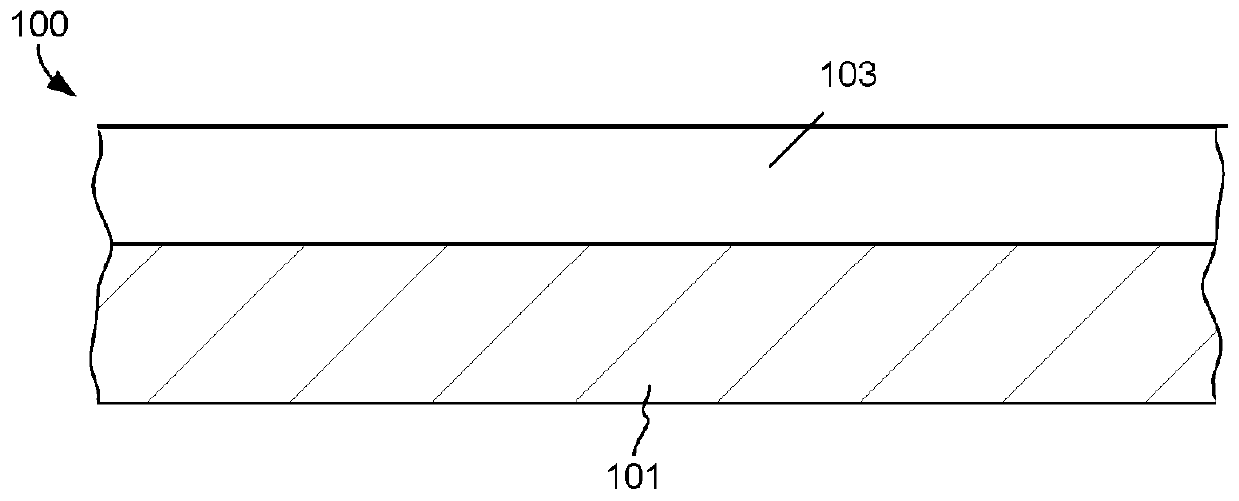

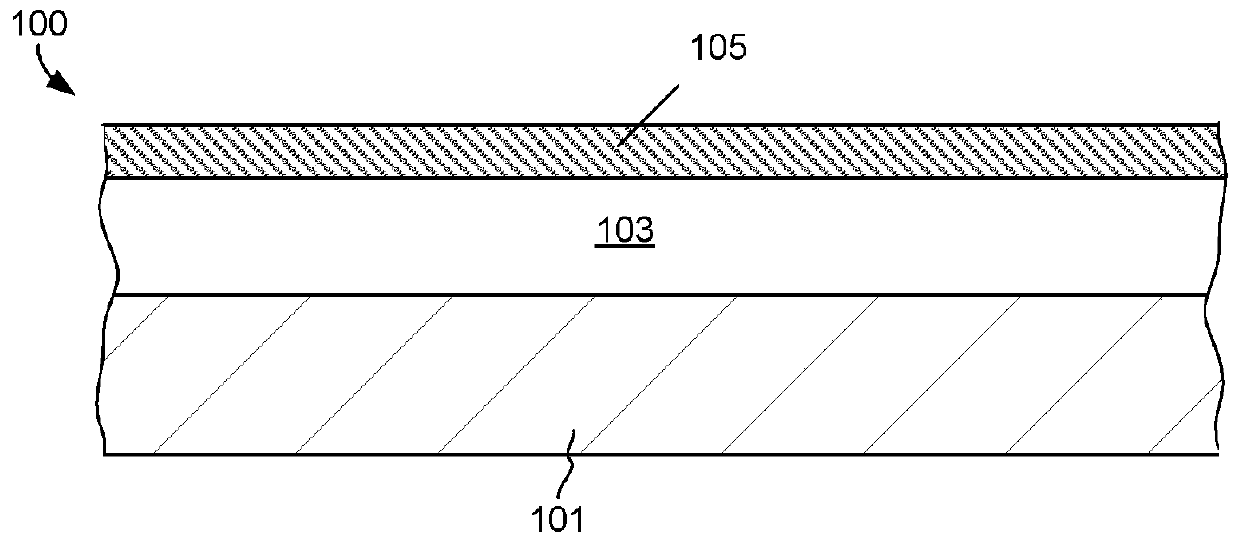

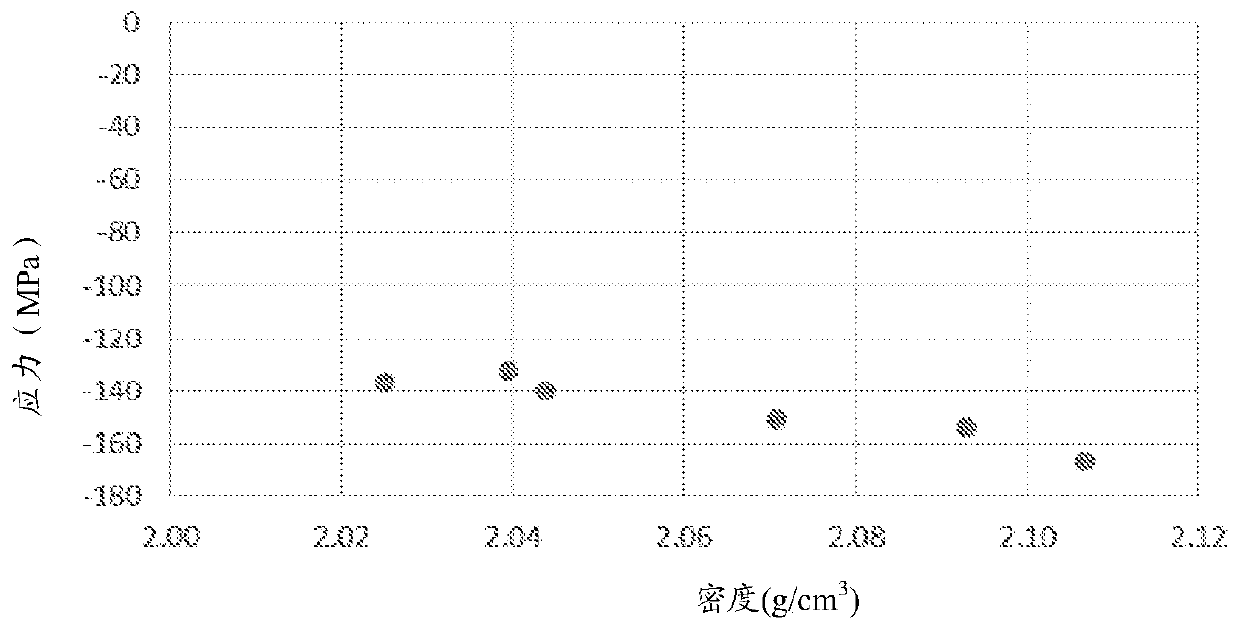

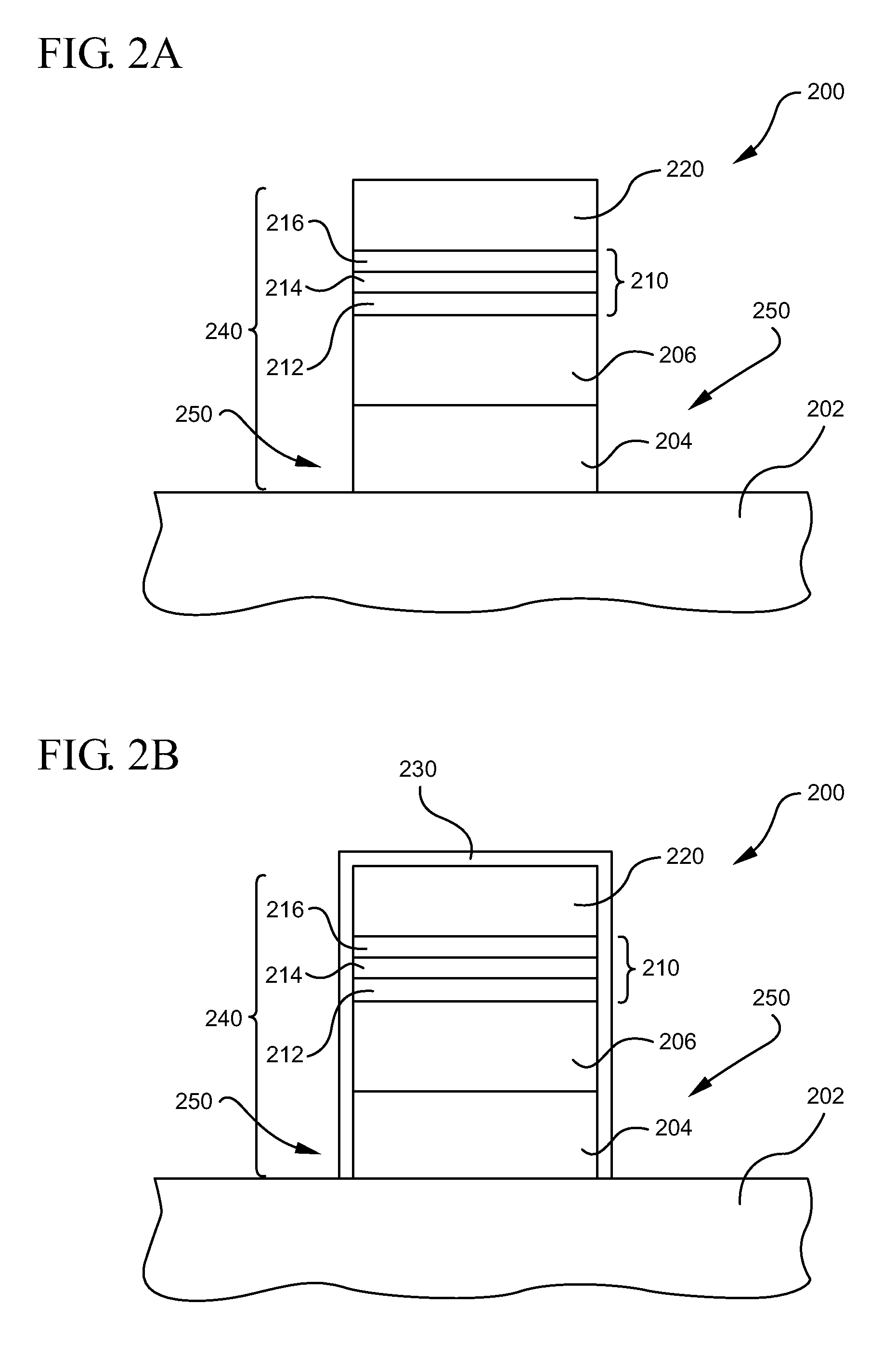

Silicon oxide layer is deposited on a semiconductor substrate by PECVD at a temperature of less than about 200° C. and is treated with helium plasma to reduce stress of the deposited layer to an absolute value of less than about 80 MPa. Plasma treatment reduces hydrogen content in the silicon oxide layer, and leads to low stress films that can also have high density and low roughness. In some embodiments, the film is deposited on a semiconductor substrate that contains one or more temperature-sensitive layers, such as layers of organic material or spin-on dielectric that cannot withstand temperatures of greater than 250° C. In some embodiments the silicon oxide film is deposited to a thickness of between about 100-200 Å, and is used as a hardmask layer during etching of other layers on a semiconductor substrate.

Owner:LAM RES CORP

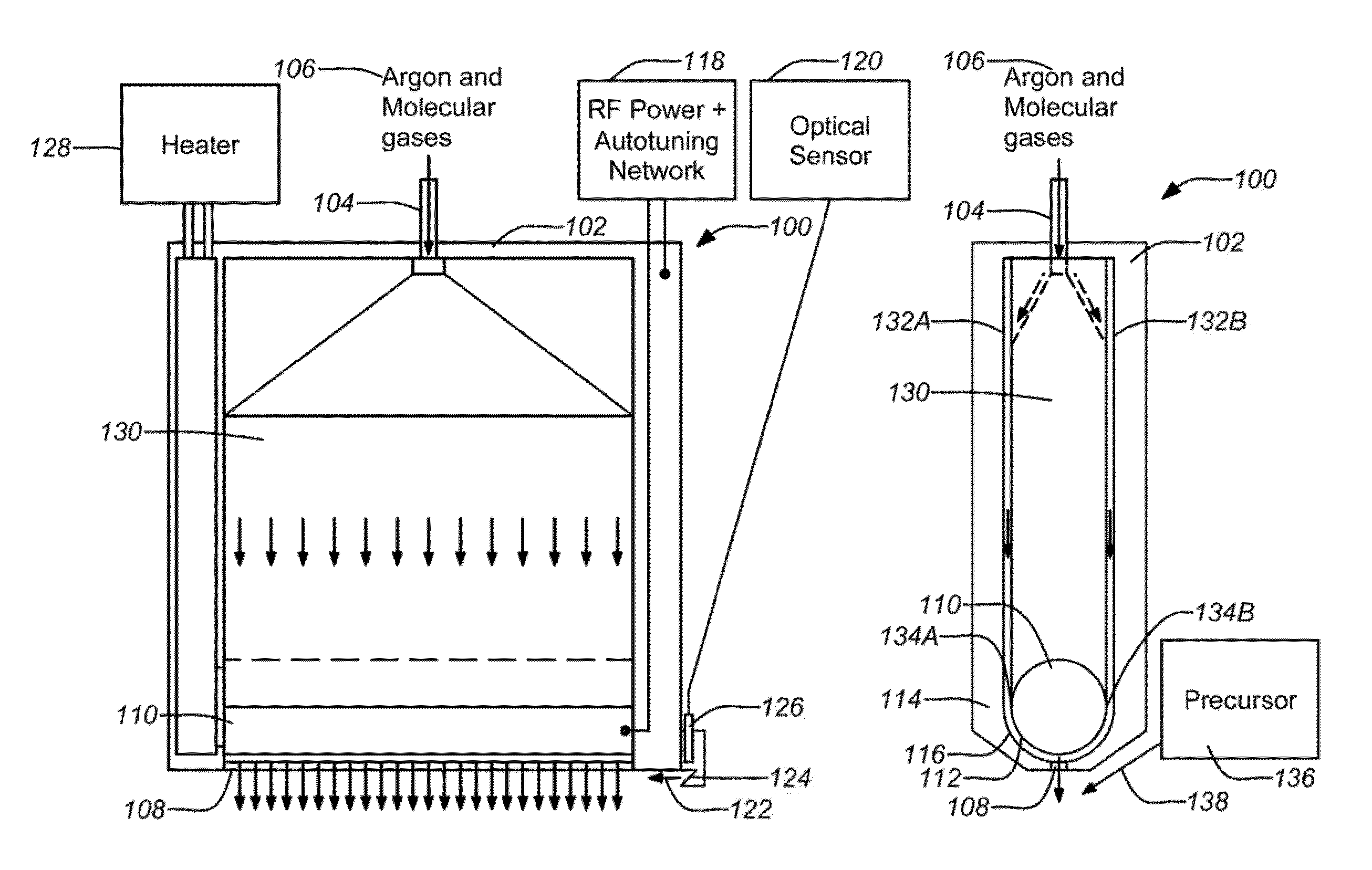

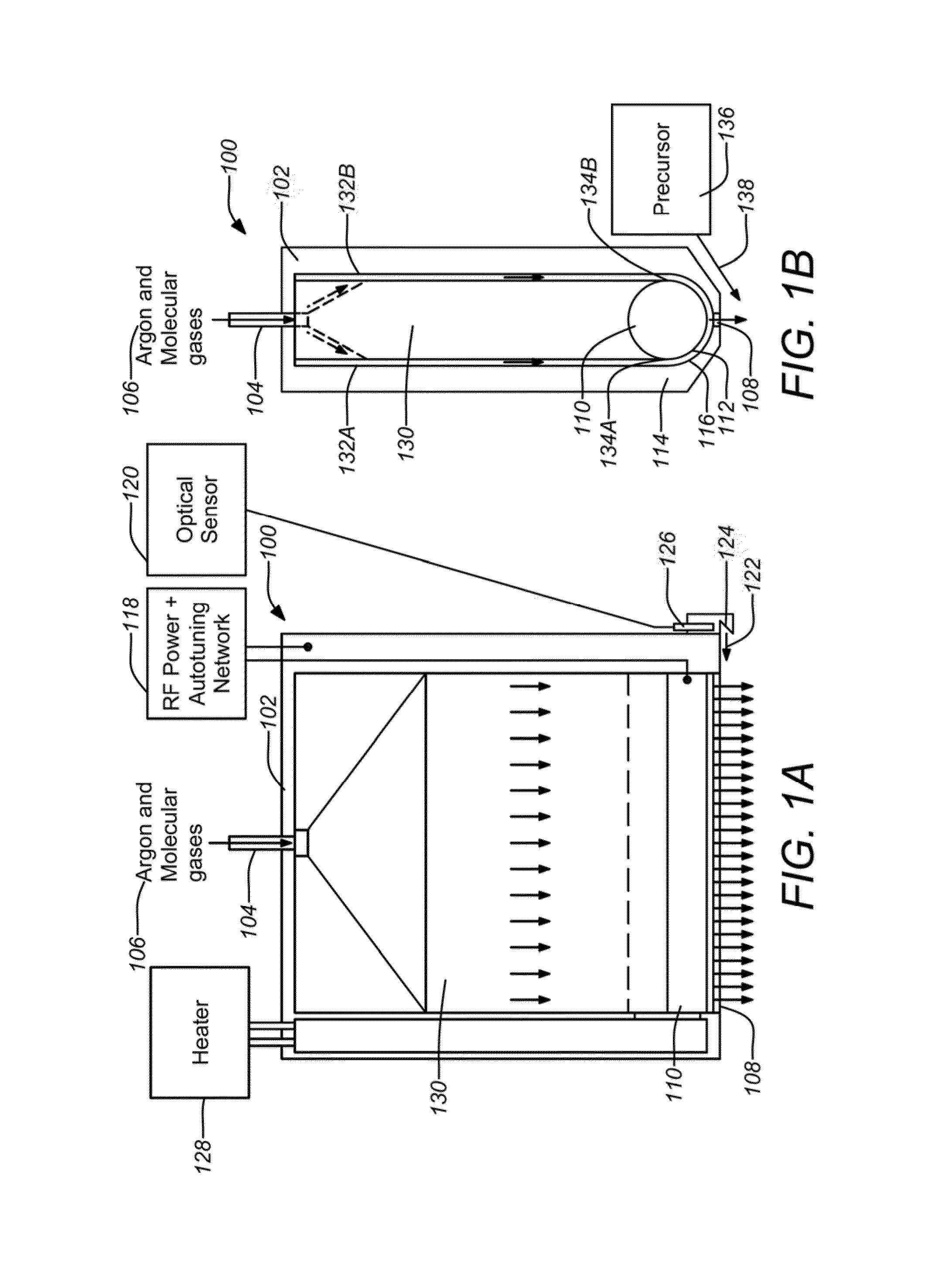

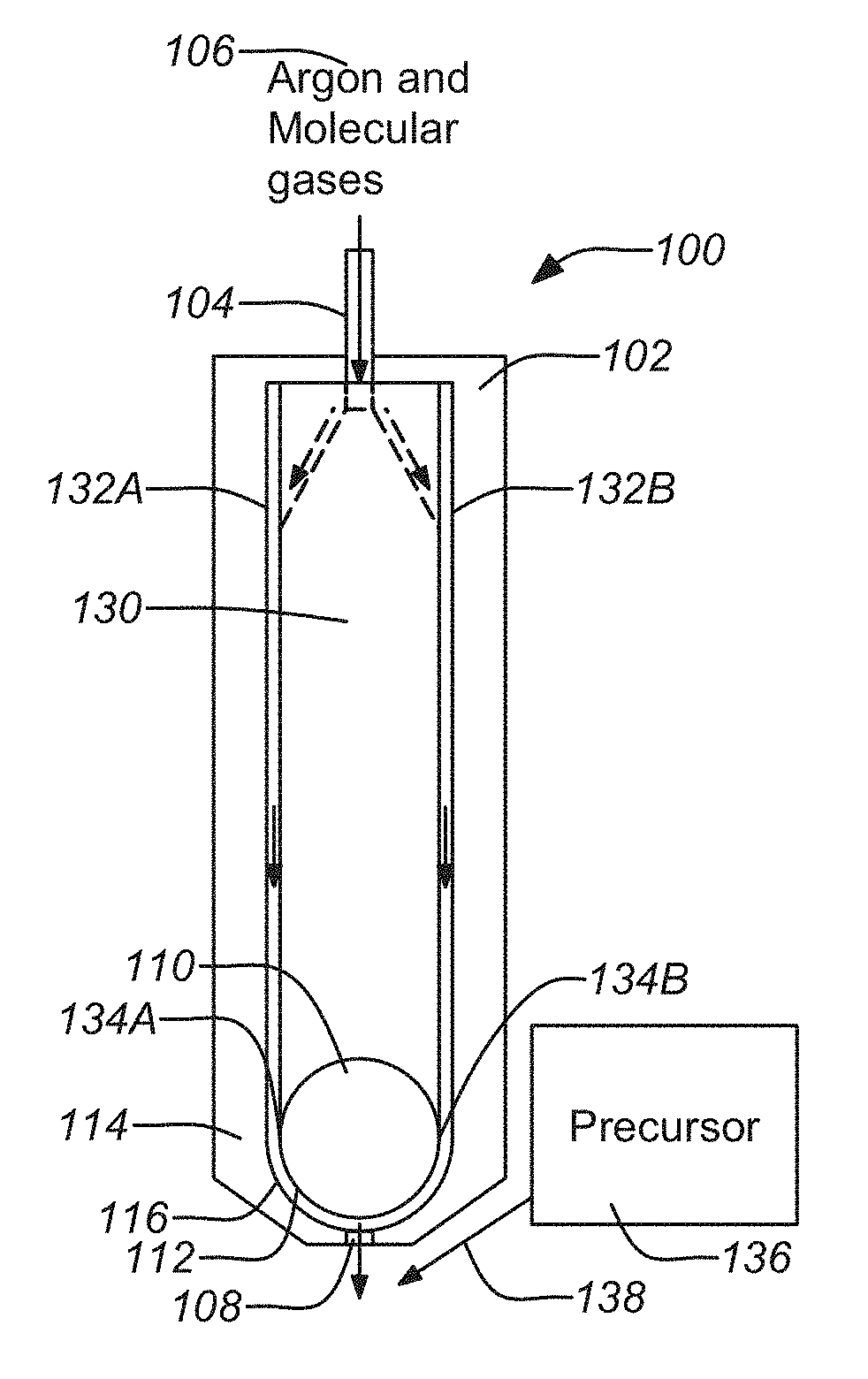

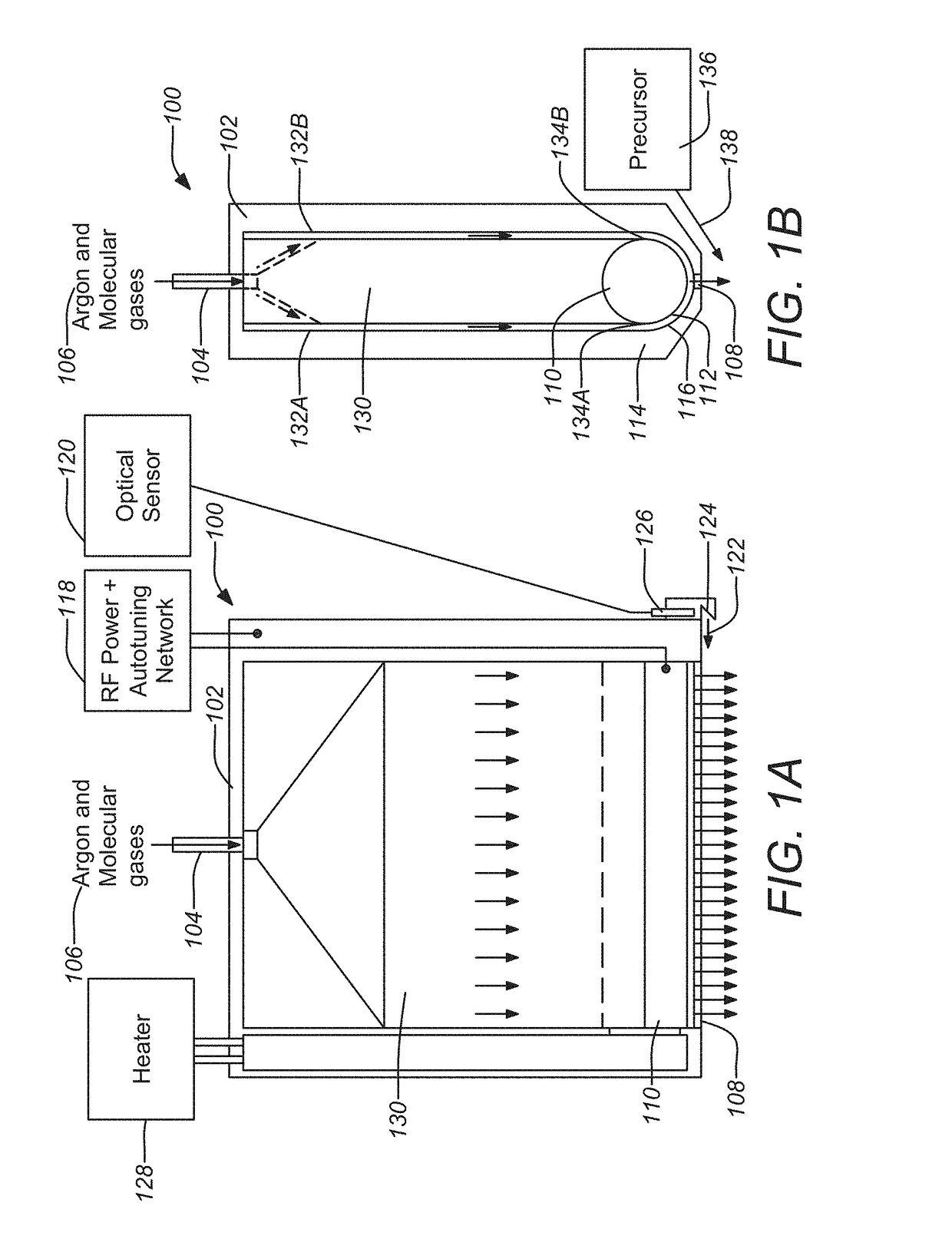

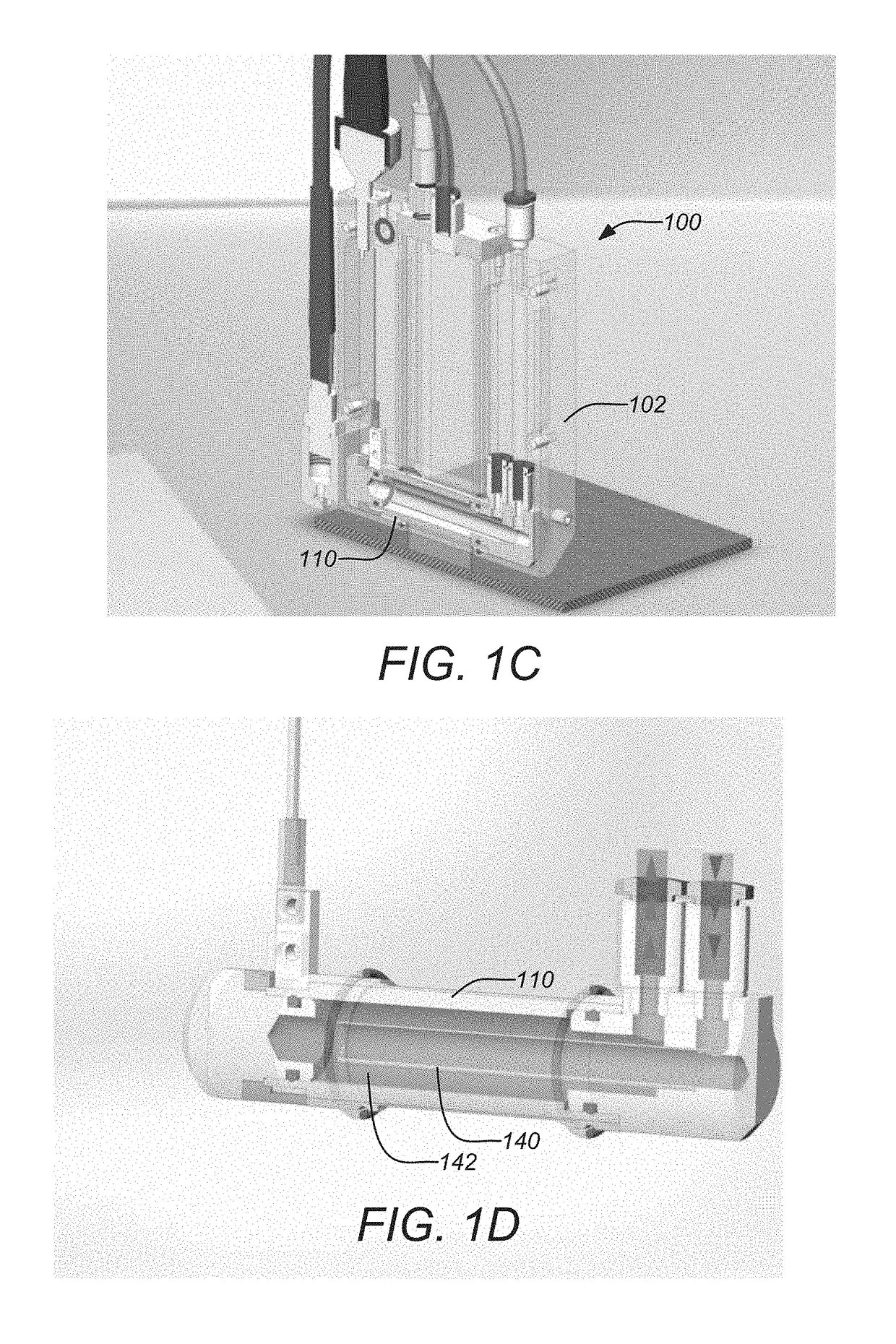

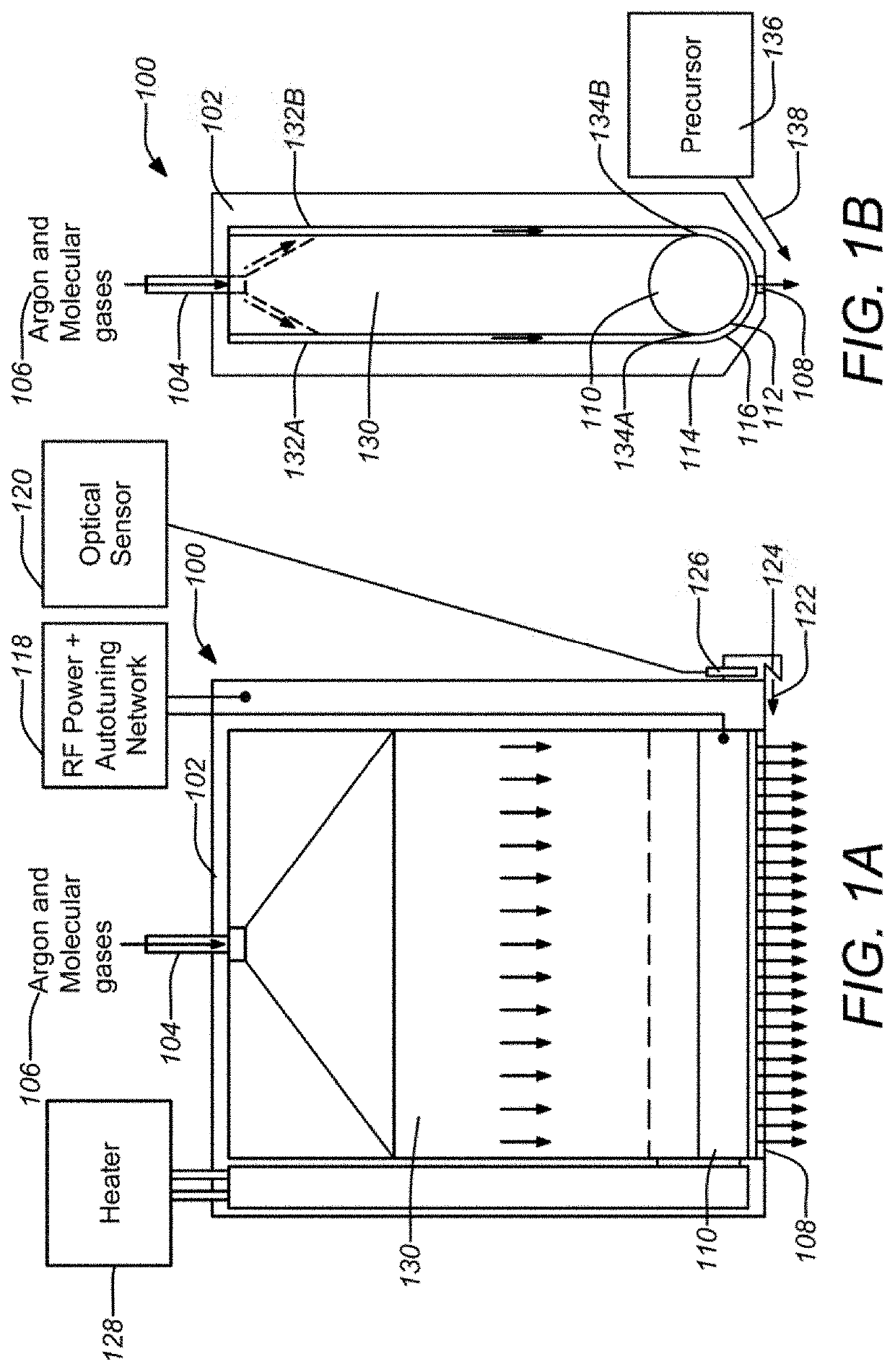

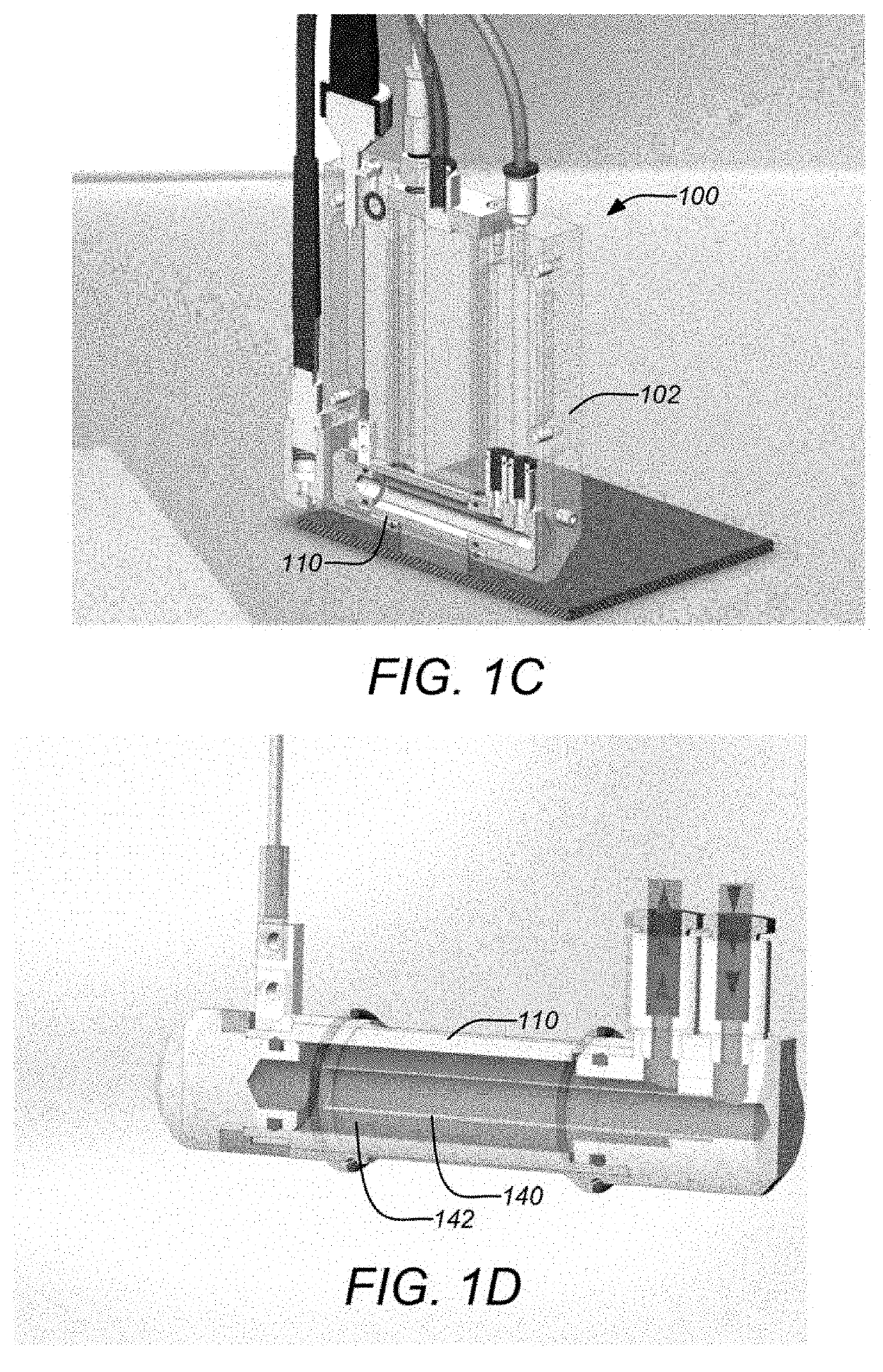

Argon and helium plasma apparatus and methods

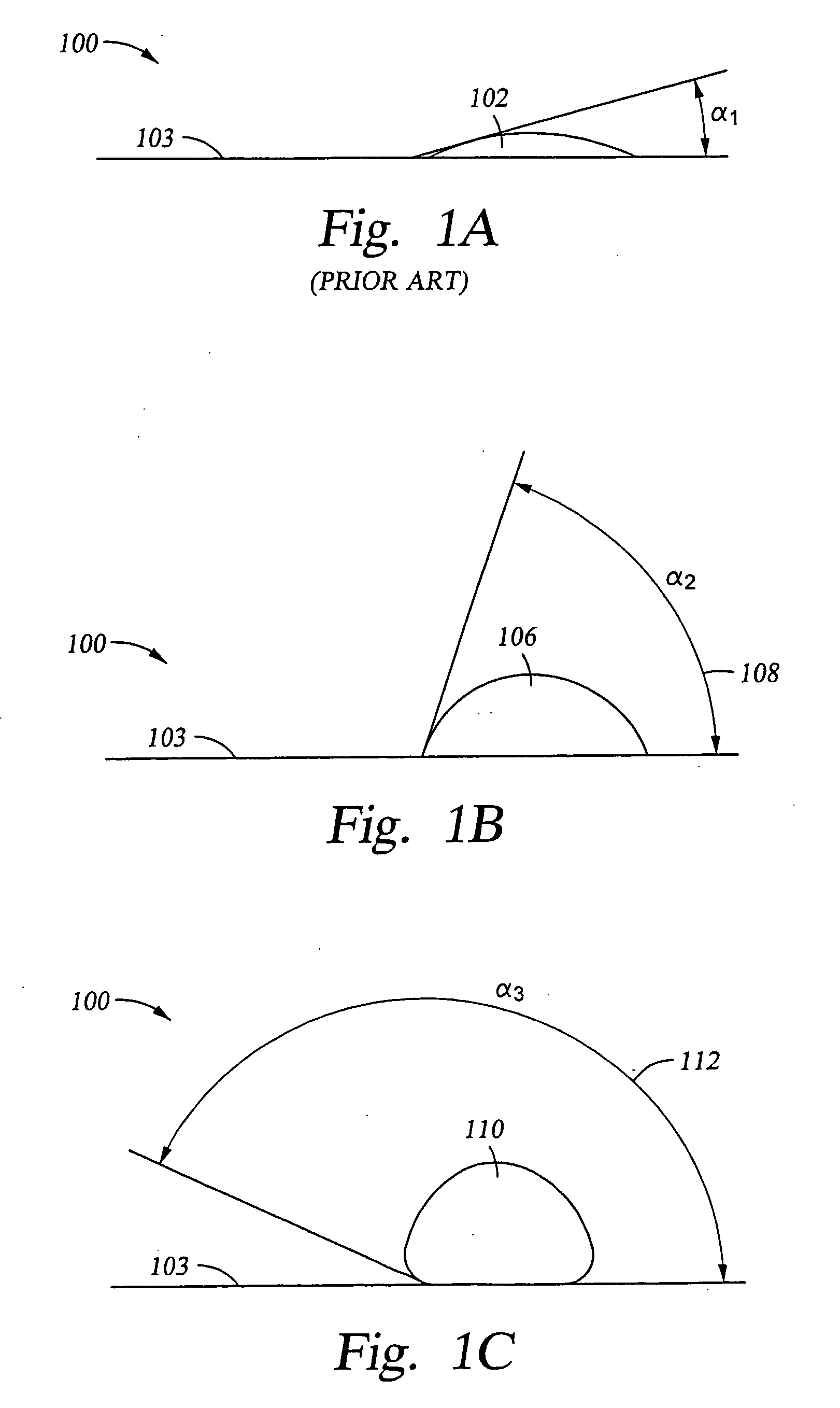

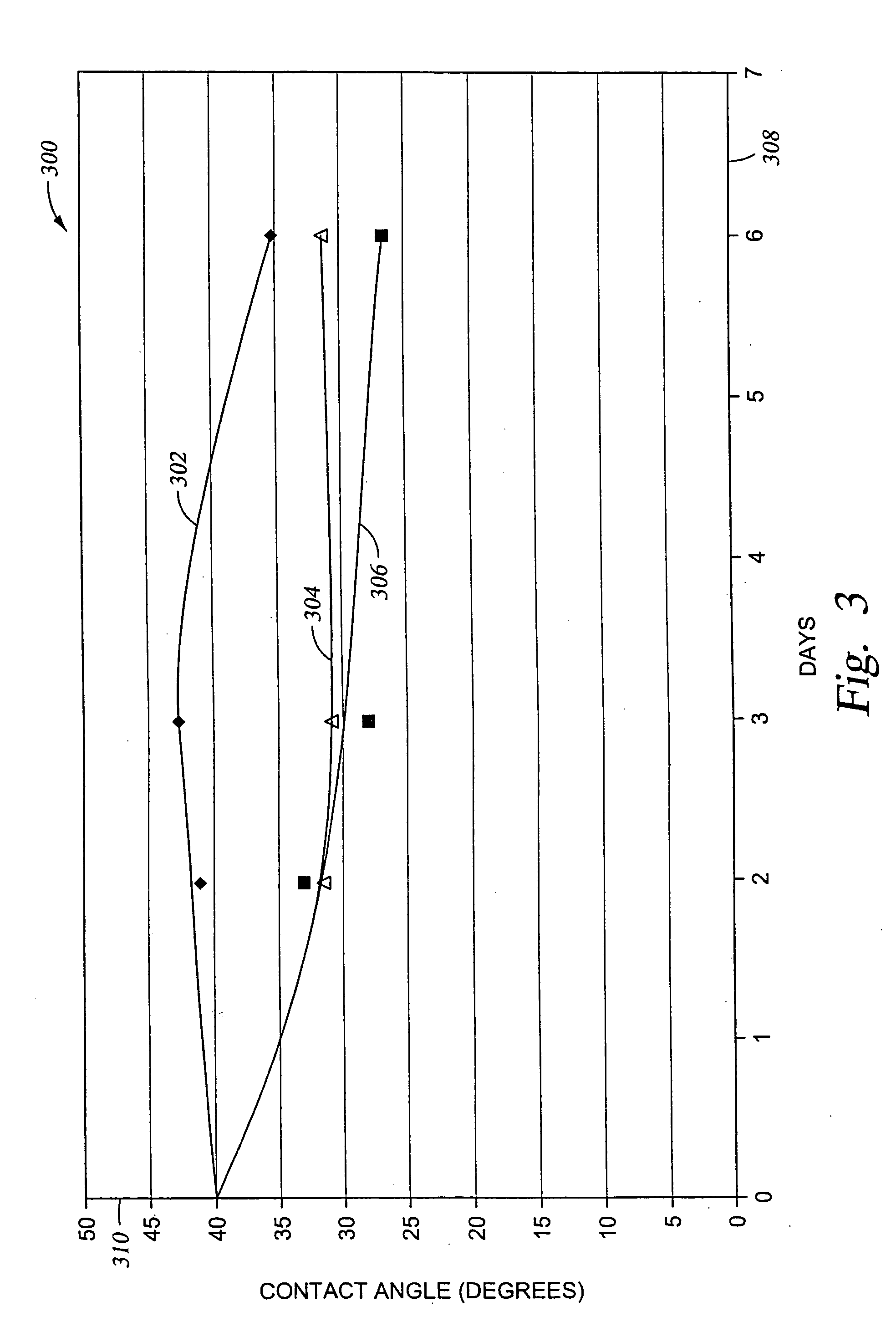

ActiveUS9406485B1High surface energyImprove adhesionElectric discharge tubesElectric discharge lampsHigh concentrationAdhesive

An argon and helium plasma apparatus and method are disclosed that operate with argon or helium at atmospheric pressure, and at low temperatures, and with high concentrations of reactive species in the effluent stream. Laminar gas flow is developed prior to forming the plasma and at least one of the electrodes is heated which enables operation at conditions where the argon or helium plasma would otherwise be unstable and either extinguish, or transition into an arc. The apparatus and method can be employed to remove organic materials from a substrate, thereby cleaning the substrate; activate the surfaces of materials thereby enhancing adhesion between the material and an adhesive; kill microorganisms on a surface, thereby sterilizing the substrate; etches thin films of materials from a substrate, and deposit thin films and coatings onto a substrate.

Owner:SURFX TECH

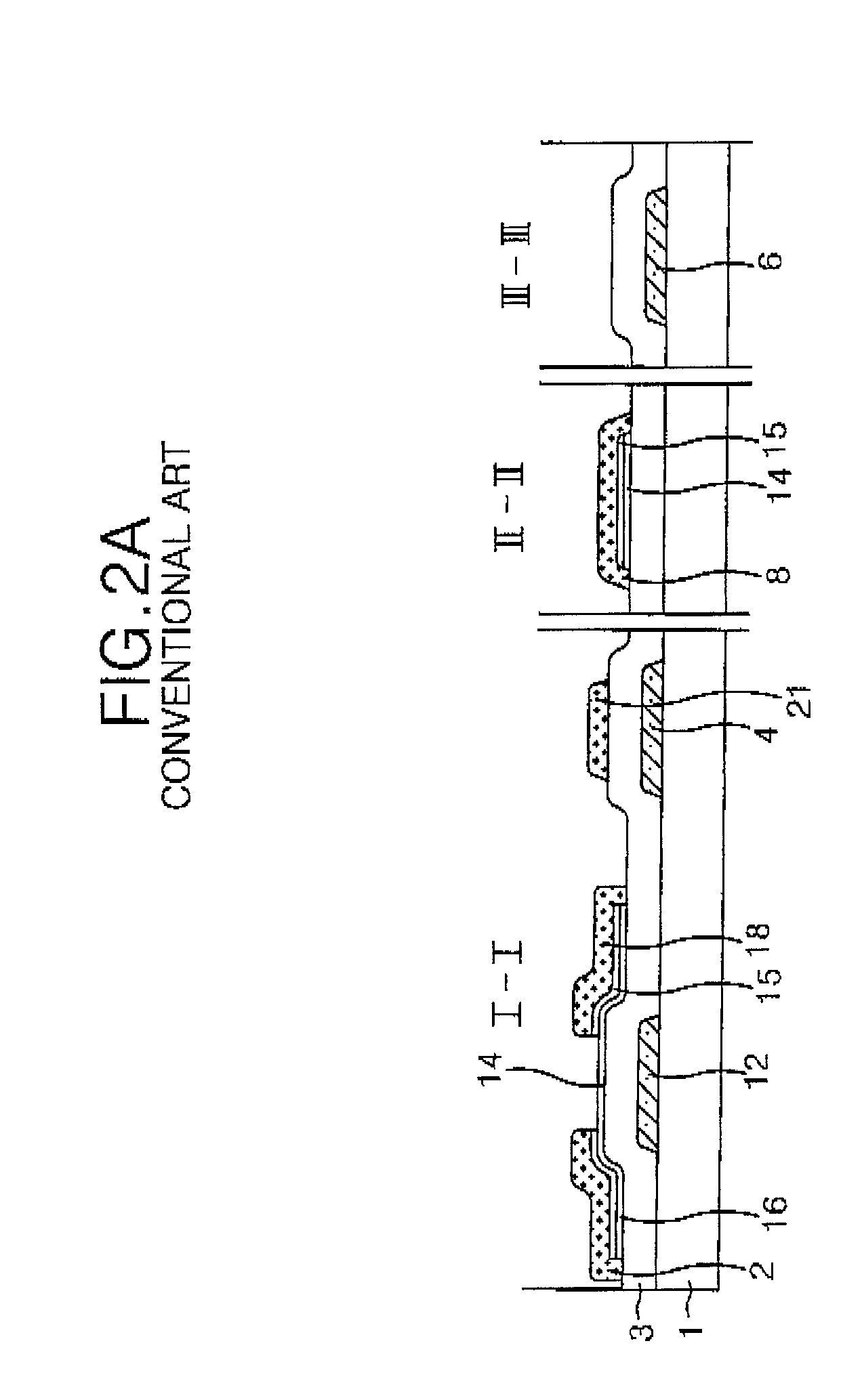

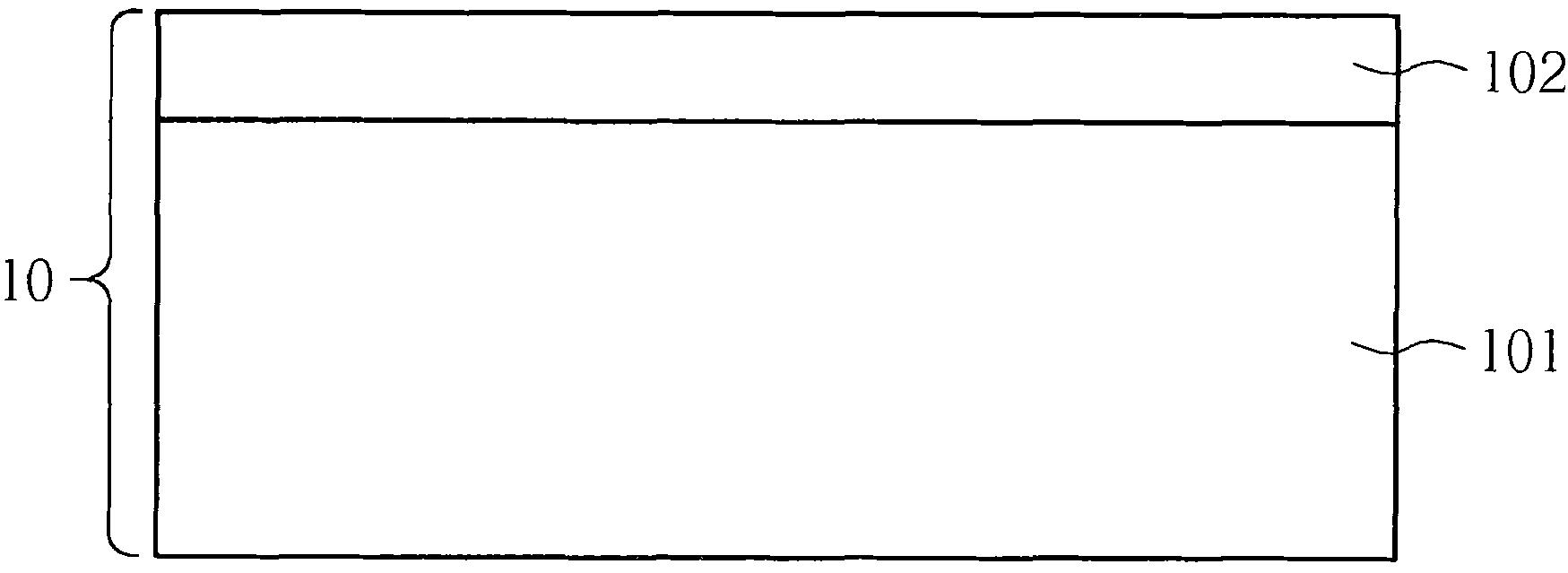

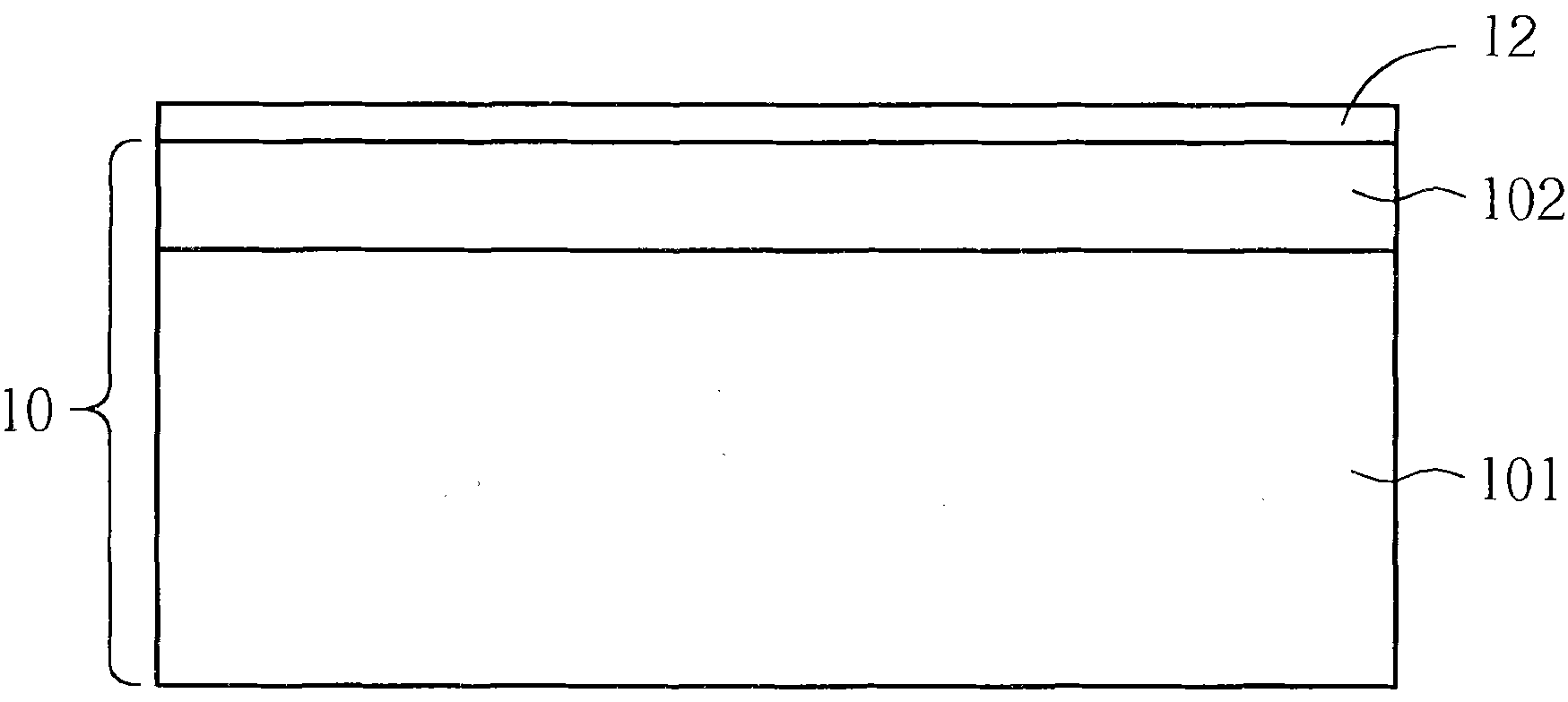

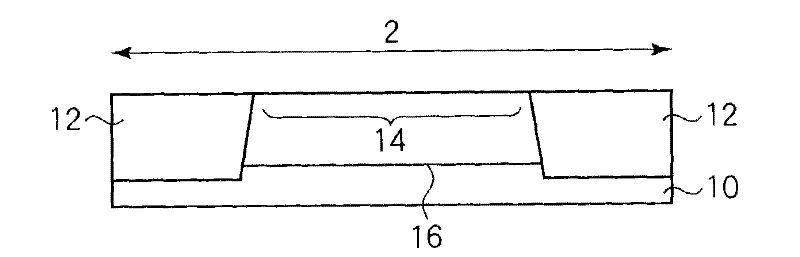

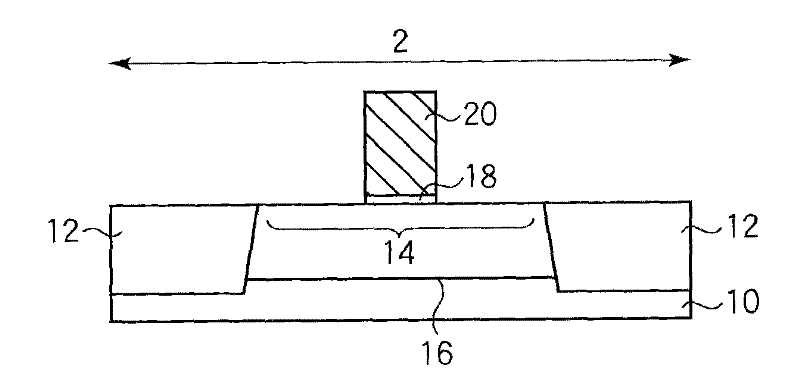

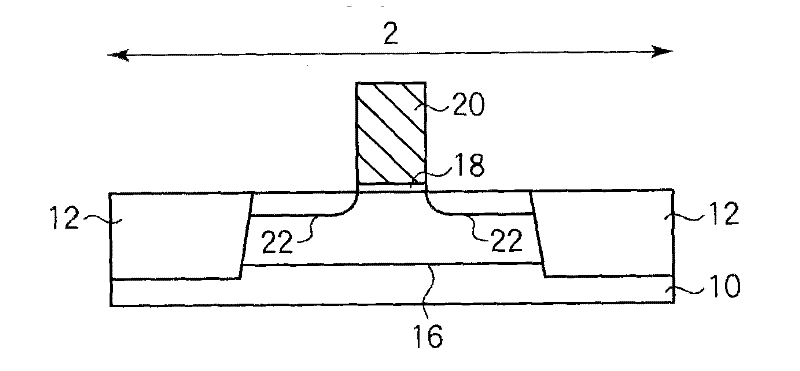

Method for treating surface of organic insulating film using helium plasma and method of fabricating thin film transistor substrate using the same

InactiveUS7133100B2High bonding strengthIncrease productionTransistorSolid-state devicesOptoelectronicsPellicle membrane

A fabricating method of a thin film transistor substrate according to the present invention includes the steps of forming on a substrate material a thin film transistor array including a plurality of signal lines; forming an organic insulating film on the substrate material on which the thin film transistor array has formed; patterning the organic insulating film; performing a surface treatment on a surface of the organic insulating film using helium plasma; and forming a transparent electrode layer on the organic insulating film.

Owner:LG DISPLAY CO LTD

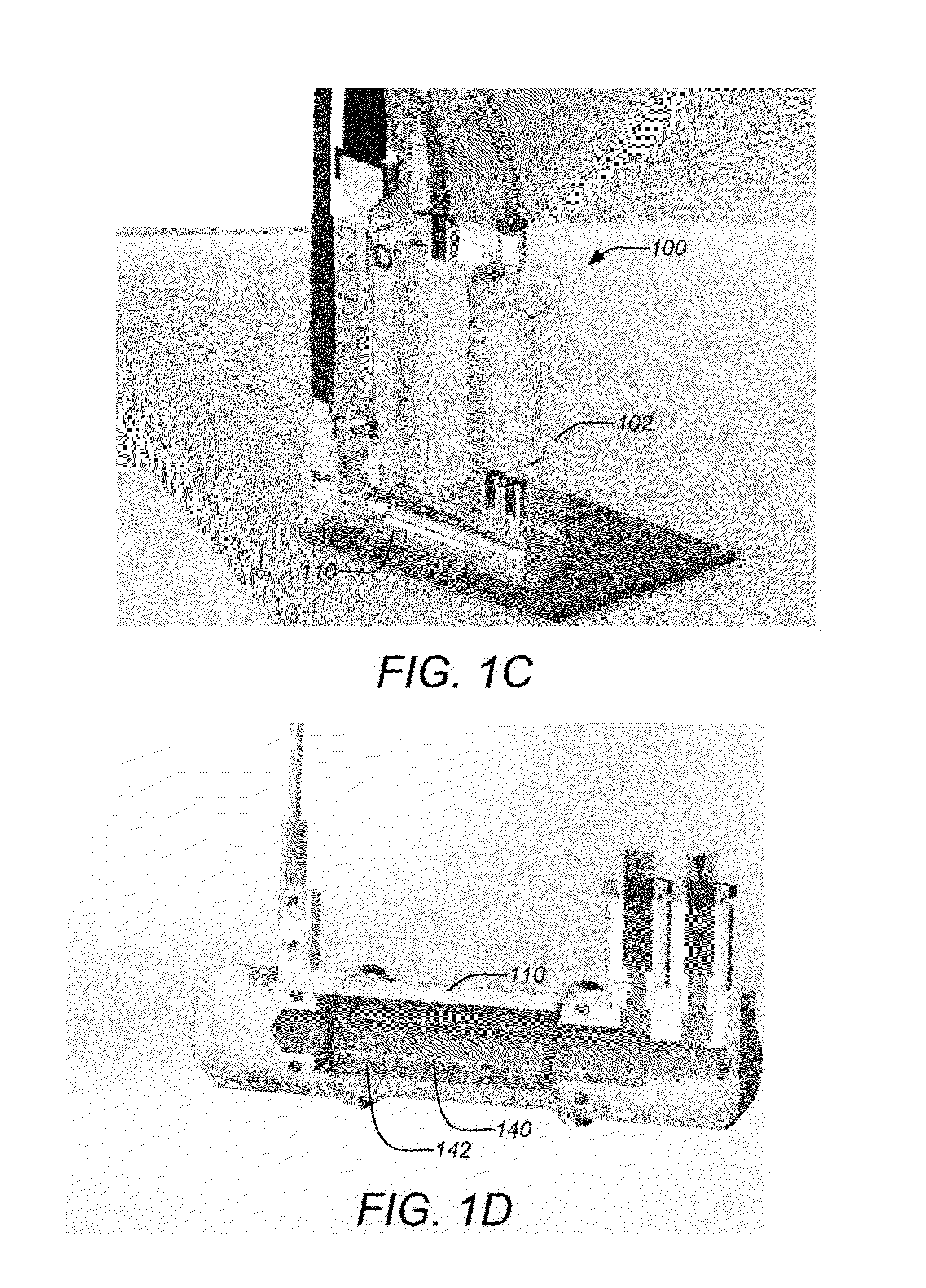

Method of film formation, insulating film, and substrate for semiconductor

InactiveUS6890605B2Improve adhesionRadiation applicationsSemiconductor/solid-state device manufacturingNitrogen plasmaUltraviolet

An insulating film for semiconductors which has excellent adhesion to films formed by CVD and is useful as a dielectric film in semiconductor devices and the like is provided. The insulating film is obtained by a method comprising:(A) a step of subjecting a substrate to at least either of (A-1) at least one treatment selected from the group consisting of an ultraviolet irradiation treatment, an oxygen plasma treatment, a nitrogen plasma treatment, a helium plasma treatment, an argon plasma treatment, a hydrogen plasma treatment and an ammonia plasma treatment, and (A-2) a treatment with at least one of alkoxysilane compound having a reactive group and a product of the hydrolysis and condensation thereof; and(B) a step of applying a composition for film formation which comprises an organic solvent and either or both of at least one compound selected from the group consisting of compounds represented by the general formulae (1) to (4) as described hereinabove, and a hydrolysis / condensation product obtained by hydrolyzing and condensing the at least one compound, to the substrate and heating the resulting coating.

Owner:JSR CORPORATIOON

Method of film formation, insulating film, and substrate for semiconductor

An insulating film for semiconductors which has excellent adhesion to films formed by CVD and is useful as a dielectric film in semiconductor devices and the like is provided. The insulating film is obtained by a method comprising: (A) a step of subjecting a substrate to at least either of (A-1) at least one treatment selected from the group consisting of an ultraviolet irradiation treatment, an oxygen plasma treatment, a nitrogen plasma treatment, a helium plasma treatment, an argon plasma treatment, a hydrogen plasma treatment and an ammonia plasma treatment, and (A-2) a treatment with at least one of alkoxysilane compound having a reactive group and a product of the hydrolysis and condensation thereof; and (B) a step of applying a composition for film formation which comprises an organic solvent and either or both of at least one compound selected from the group consisting of compounds represented by the general formulae (1) to (4) as described hereinabove, and a hydrolysis / condensation product obtained by hydrolyzing and condensing the at least one compound, to the substrate and heating the resulting coating.

Owner:JSR CORPORATIOON

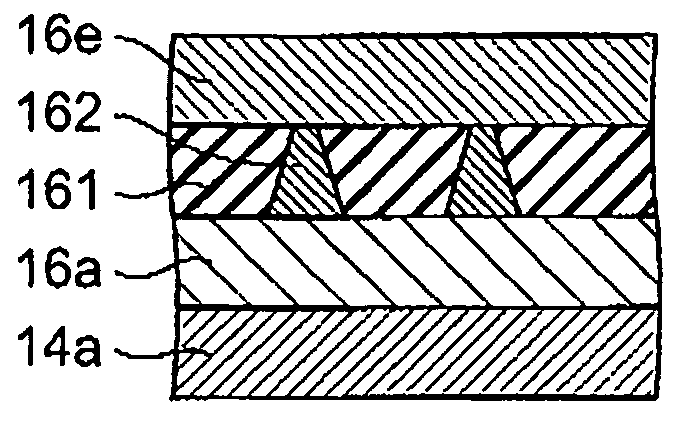

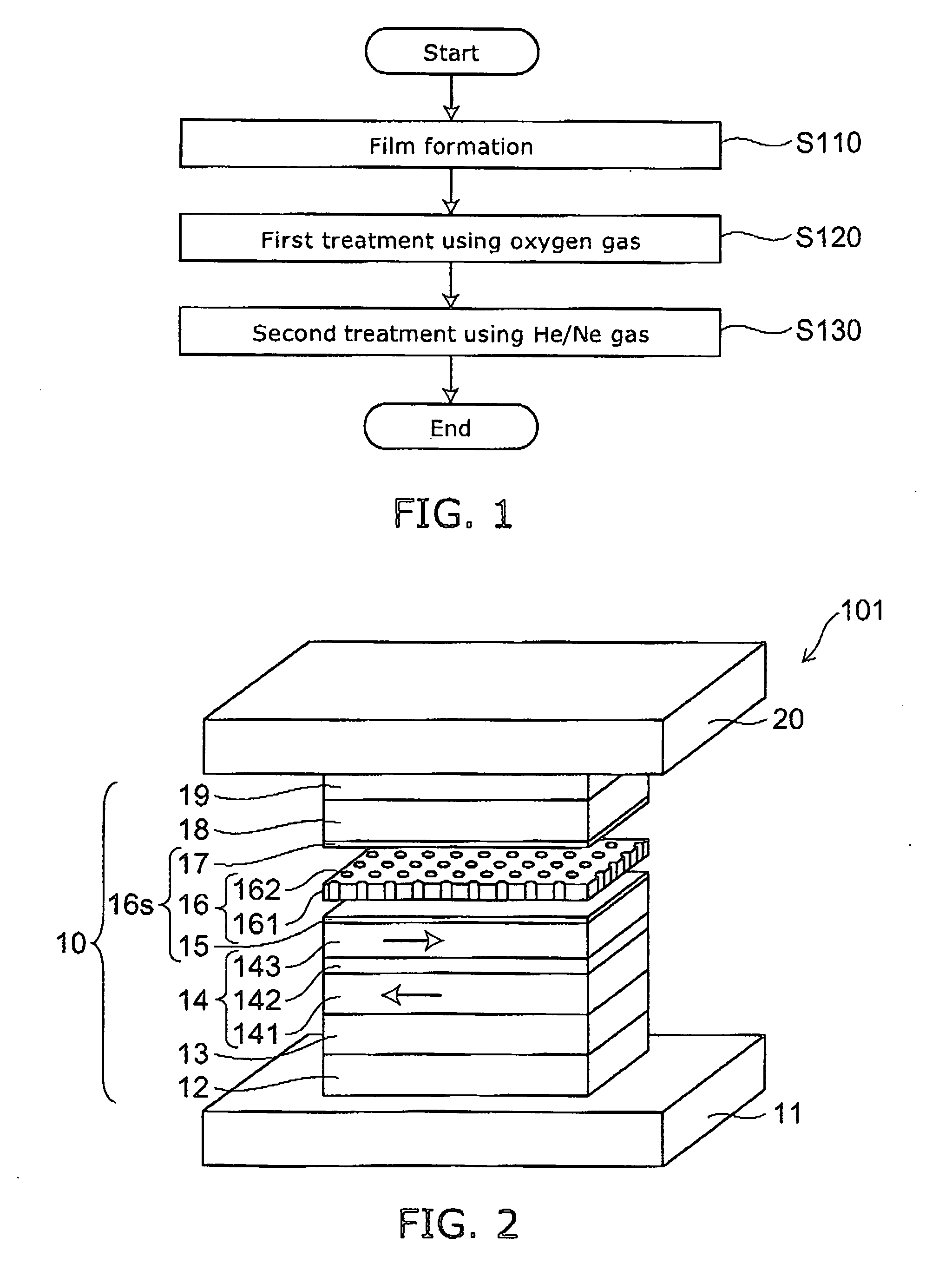

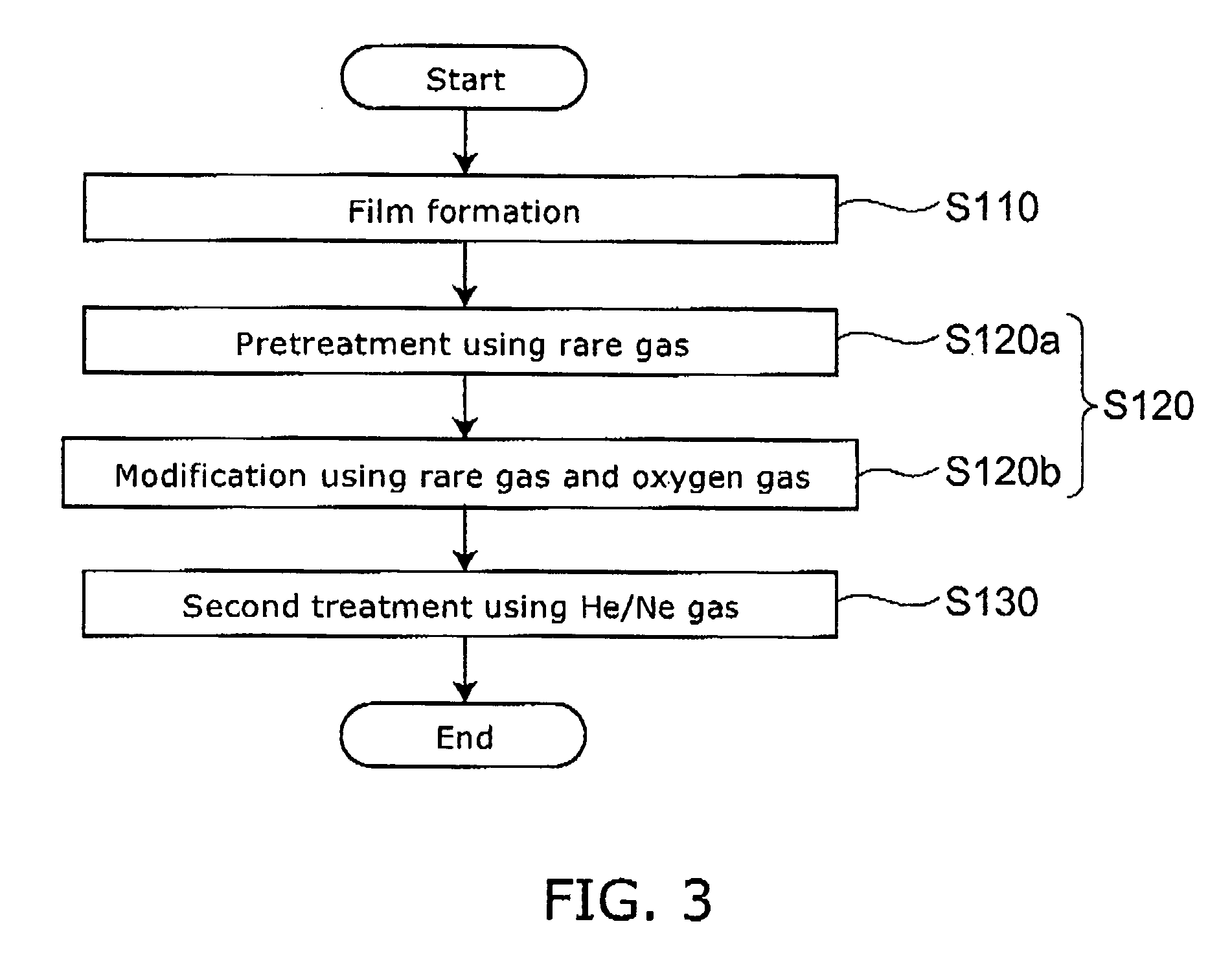

Method for manufacturing a magneto-resistance effect element and magnetic recording and reproducing apparatus

A method for manufacturing a magneto-resistance effect element is provided. The magneto-resistance effect element includes a first magnetic layer including a ferromagnetic material, a second magnetic layer including a ferromagnetic material and a spacer layer provided between the first magnetic layer and the second magnetic layer, the spacer layer having an insulating layer and a conductive portion penetrating through the insulating layer. The method includes: forming a film to be a base material of the spacer layer; performing a first treatment using a gas including at least one of oxygen molecules, oxygen atoms, oxygen ions, oxygen plasma and oxygen radicals on the film; and performing a second treatment using a gas including at least one of helium ions, helium plasma, helium radicals, neon ions, neon plasma and neon radicals on the film submitted to the first treatment.

Owner:TDK CORPARATION +1

Low temperature atmospheric pressure plasma applications

ActiveUS10032609B1High surface energyImprove adhesionElectric discharge tubesChemical vapor deposition coatingHigh concentrationAdhesive

Plasma applications are disclosed that operate with helium or argon at atmospheric pressure, and at low temperatures, and with high concentrations of reactive species in the effluent stream. Laminar gas flow is developed prior to forming the plasma and at least one of the electrodes is heated which enables operation at conditions where the helium plasma would otherwise be unstable and either extinguish, or transition into an arc. The techniques can be employed to remove organic materials from a substrate, thereby cleaning the substrate; activate the surfaces of materials thereby enhancing adhesion between the material and an adhesive; kill microorganisms on a surface, thereby sterilizing the substrate; etches thin films of materials from a substrate, and deposit thin films and coatings onto a substrate.

Owner:SURFX TECH

Integrated circuit device and fabrication using metal-doped chalcogenide materials

InactiveUS20050026433A1Reduces contamination concernReduce physical damageVacuum evaporation coatingSolid-state devicesNoble gasContamination

Methods of forming metal-doped chalcogenide layers and devices containing such doped chalcogenide layers include using a plasma to induce diffusion of metal into a chalcogenide layer concurrently with metal deposition. The plasma contains at least one noble gas of low atomic weight, such as neon or helium. The plasma has a sputter yield sufficient to sputter a metal target and a UV component of its emitted spectrum sufficient to induce diffusion of the sputtered metal into the chalcogenide layer. Using such methods, a conductive layer can be formed on the doped chalcogenide layer in situ. In integrated circuit devices, such as non-volatile chalcogenide memory devices, doping of the chalcogenide layer concurrently with metal deposition and formation of a conductive layer in situ with the doping of the chalcogenide layer reduces contamination concerns and physical damage resulting from moving the device substrate from tool to tool, thus facilitating improved device reliability.

Owner:LI JIUTAO +1

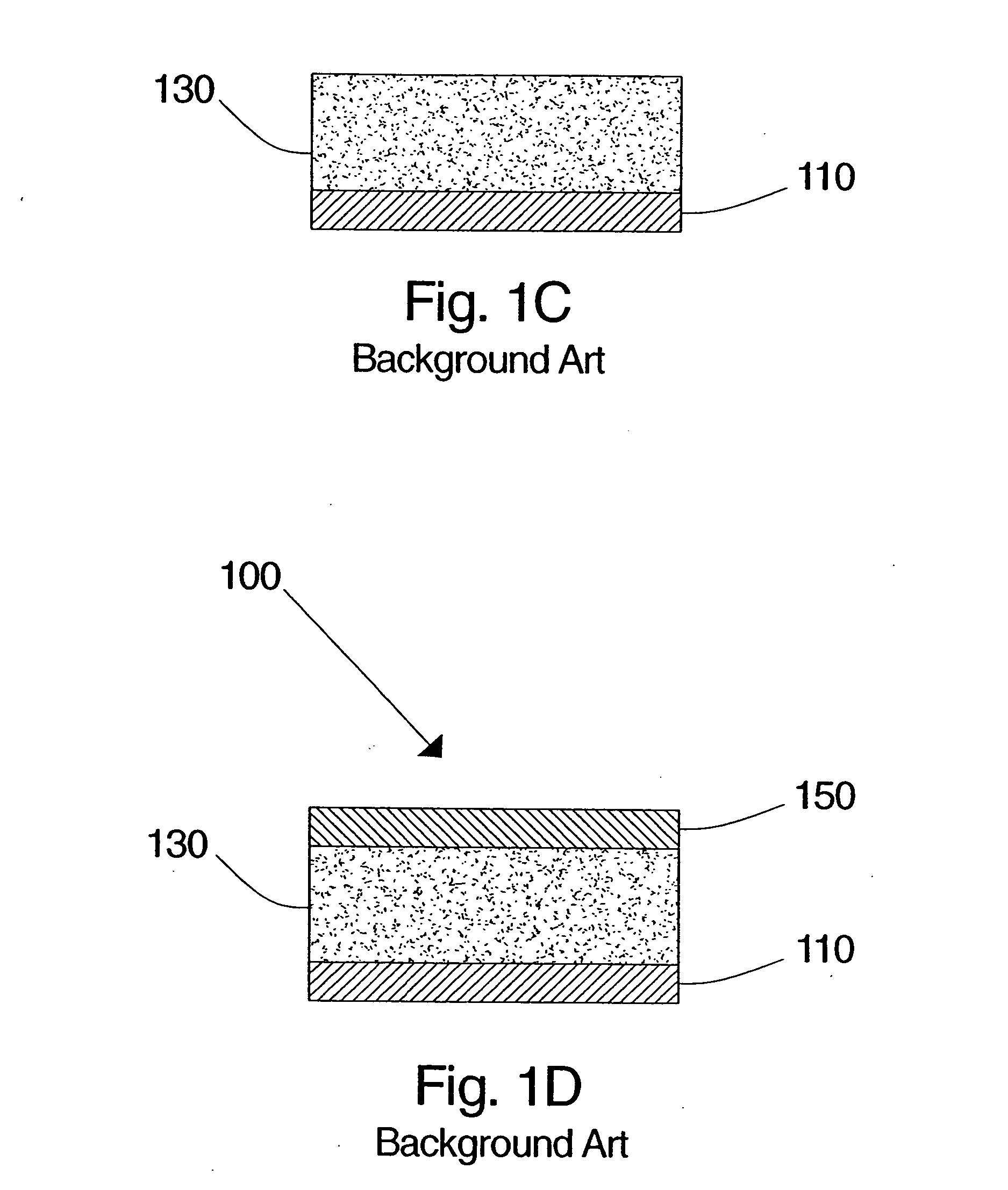

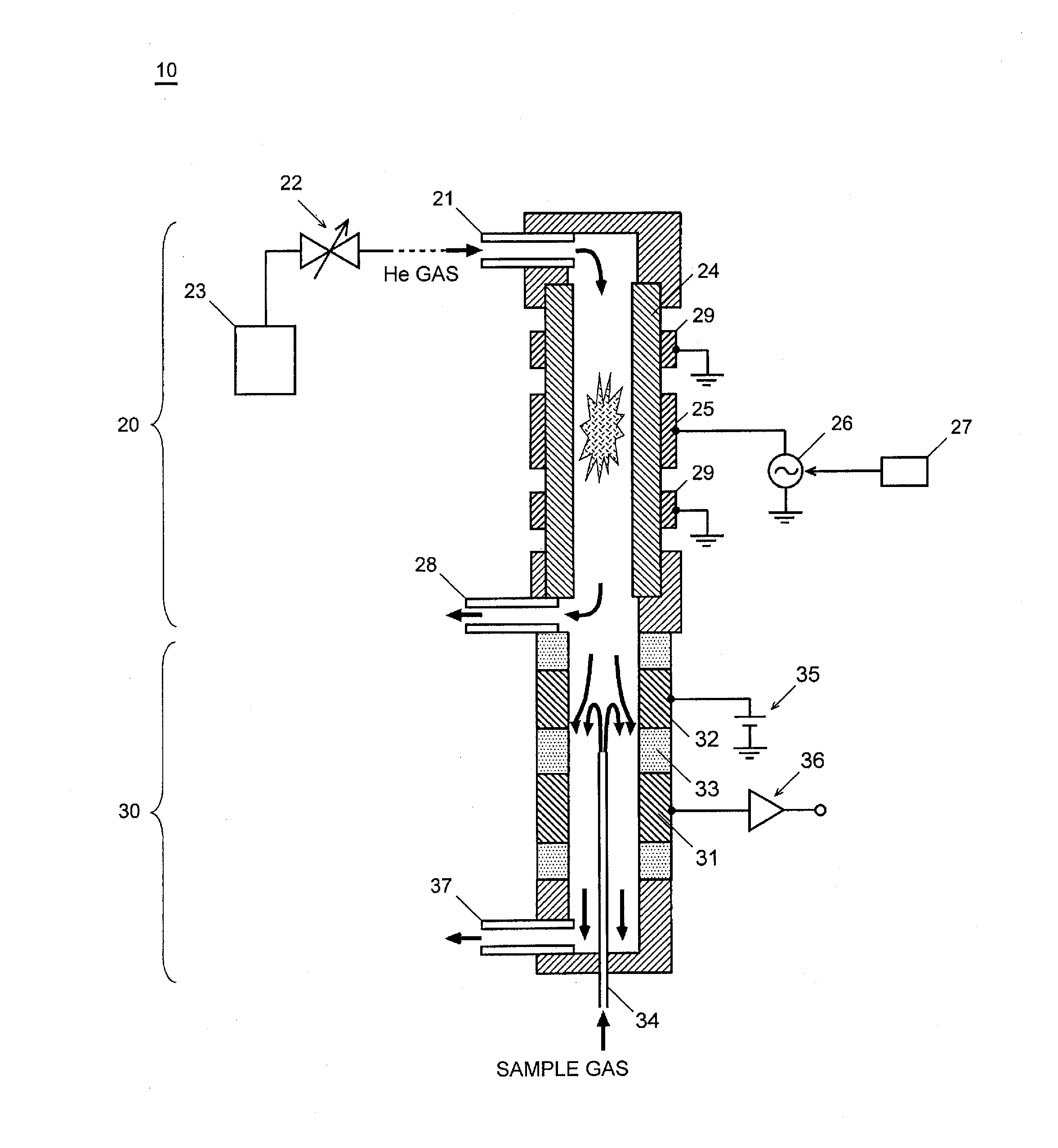

Discharge ionization current detector and tuning method for the same

ActiveUS20150369777A1Stable and strong vacuum ultraviolet lightImprove reproducibility and precisionComponent separationMaterial analysis by electric/magnetic meansVoltage amplitudeElectricity

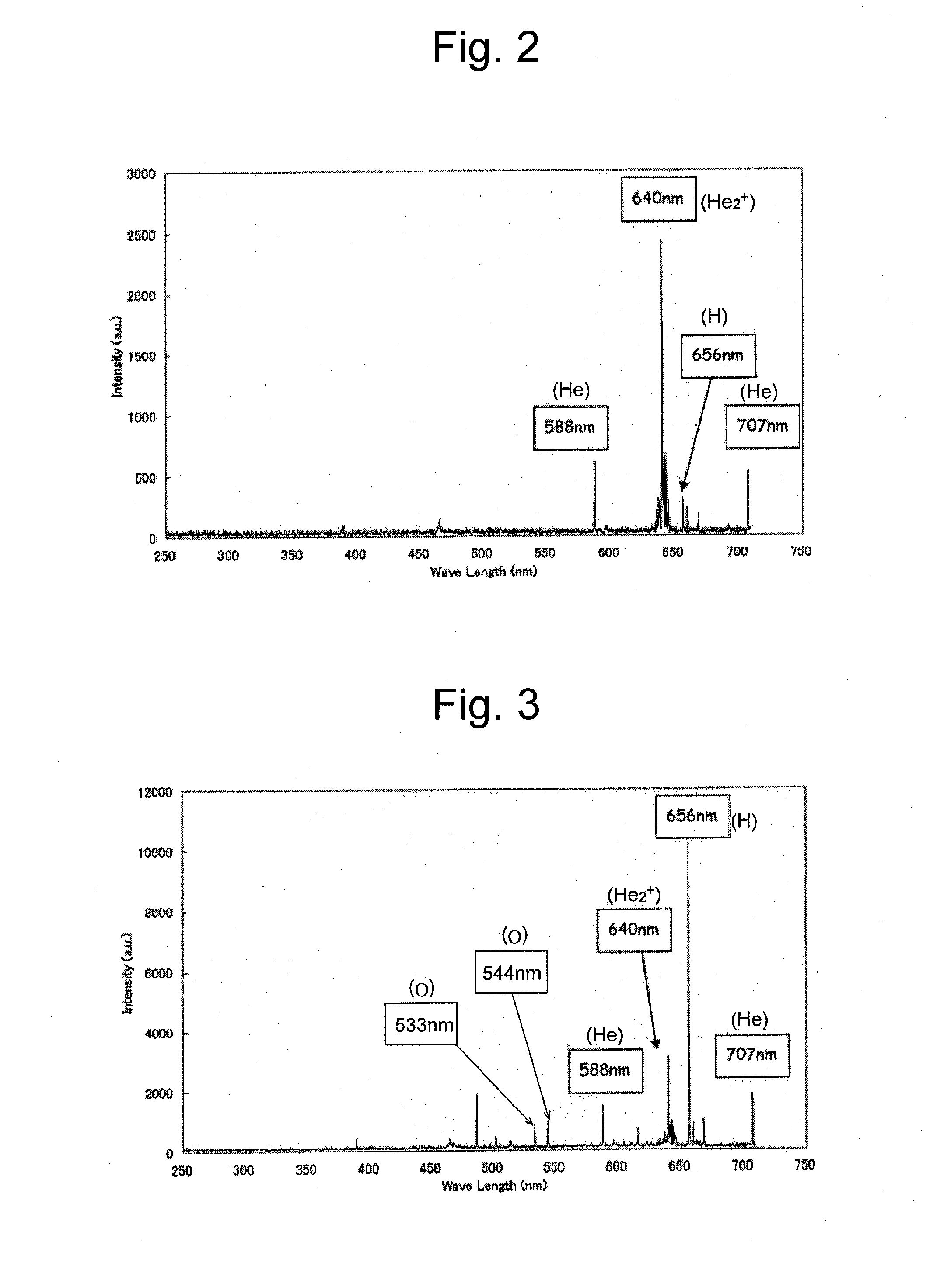

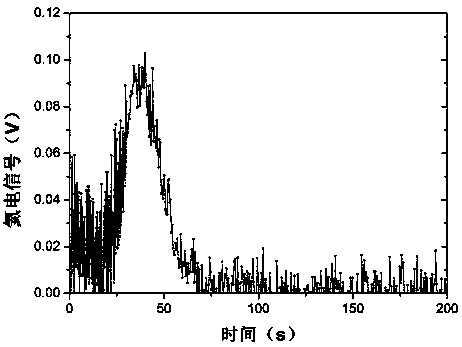

An adjusting method for a discharge ionization current detector of the present invention is provided for a discharge ionization current detector for a gas chromatograph, which improves the precision and reproducibility of measurements results of the detector. The discharge ionization current detector adjusts at least one of purity of introduced helium gas, a flow rate of the introduced helium gas, an amplitude of voltage of the low-frequency dielectric barrier discharge, and a frequency of the voltage of the low-frequency dielectric barrier discharge so that intensity of light having a wavelength of 640 nm reaches the maximum in a range of wavelengths of 250 to 700 nm with respect to light emitted by the helium plasma.

Owner:SHIMADZU CORP

Wide-range flexible resistance type pressure sensor and preparation method thereof

PendingCN113340484AWide measurement rangeThe preparation process steps are simpleTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrical resistance and conductanceConductive materials

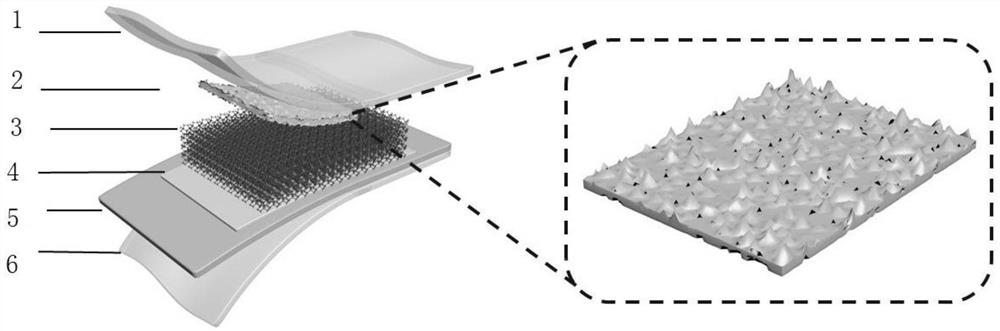

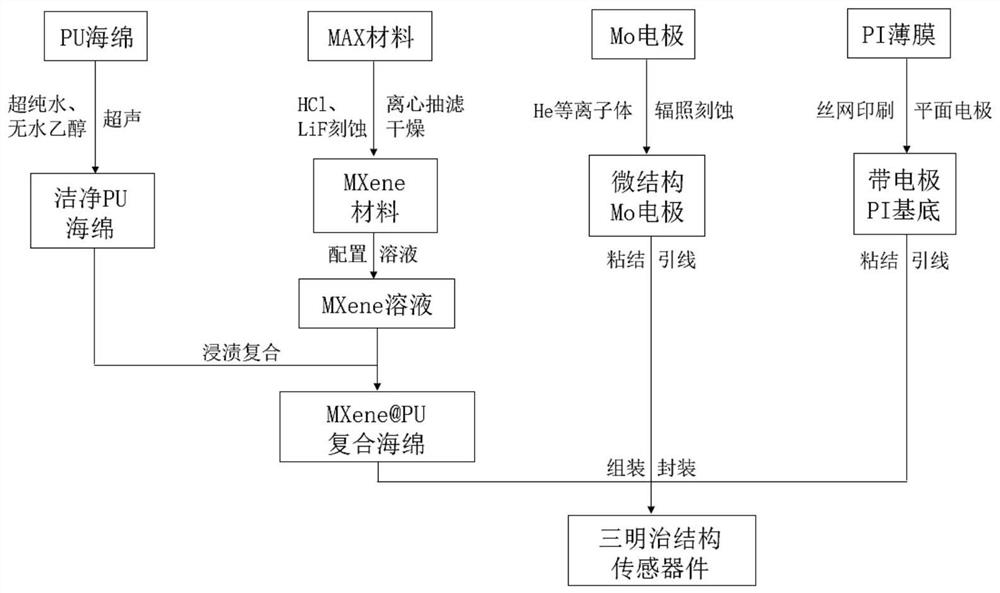

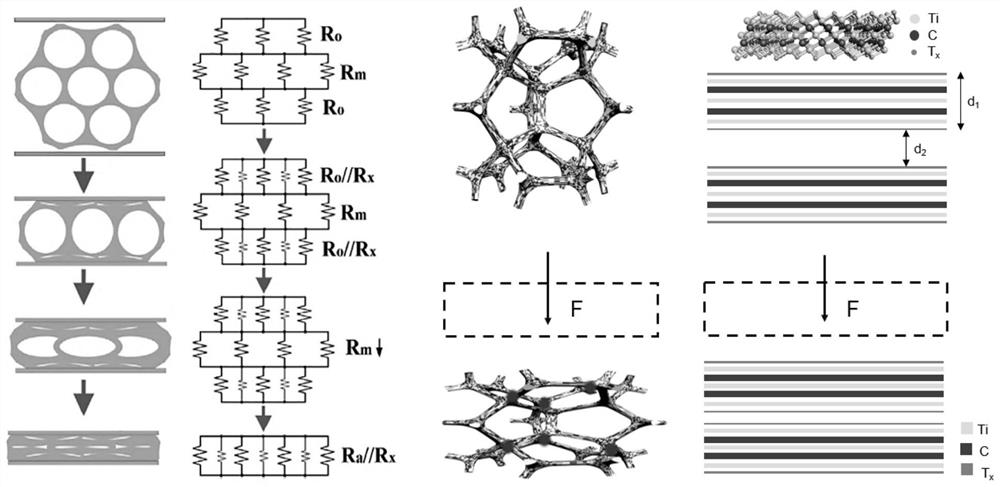

The invention provides a wide-range flexible resistance type pressure sensor and a preparation method thereof, the sensor is of a multi-layer structure, the sensor comprises a lower packaging layer, a flexible substrate layer, a first conductive electrode, a composite sponge layer, a second conductive electrode and an upper packaging layer from bottom to top in sequence, and the inner side of the second conductive electrode is subjected to helium plasma irradiation etching to obtain a nanometer fluff structure. The composite sponge layer is obtained by compounding a sponge material and a conductive material through a solution impregnation method, and the conductive material with a lamellar structure is arranged in the composite sponge layer; and according to the invention, the pressure test sensitivity is improved through full contact of the electrode nano fluff structure and the hole structure, the sponge flexible skeleton is combined with the conductive material, the deformation of the sponge and the deformation of the conductive material are fully utilized, pressure sensitive mechanism switching is realized in different pressure ranges, the pressure detection range is expanded, and good linear response is kept in a wide range. The sensor provided by the invention has the advantages of simple structure manufacturing, small volume, light weight and biological harmlessness.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Low temperature atmospheric pressure plasma for cleaning and activating metals

ActiveUS10800092B1High surface energyImprove adhesionElectric discharge heatingElectric discharge tubesHigh concentrationAtmospheric sciences

Plasma applications are disclosed that operate with argon or helium at atmospheric pressure, and at low temperatures, and with high concentrations of reactive species in the effluent stream. Laminar gas flow is developed prior to forming the plasma and at least one of the electrodes can be heated which enables operation at conditions where the argon or helium plasma would otherwise be unstable and either extinguish, or transition into an arc. The techniques can be employed to clean and activate a metal substrate, including removal of oxidation, thereby enhancing the bonding of at least one other material to the metal.

Owner:SURFX TECH

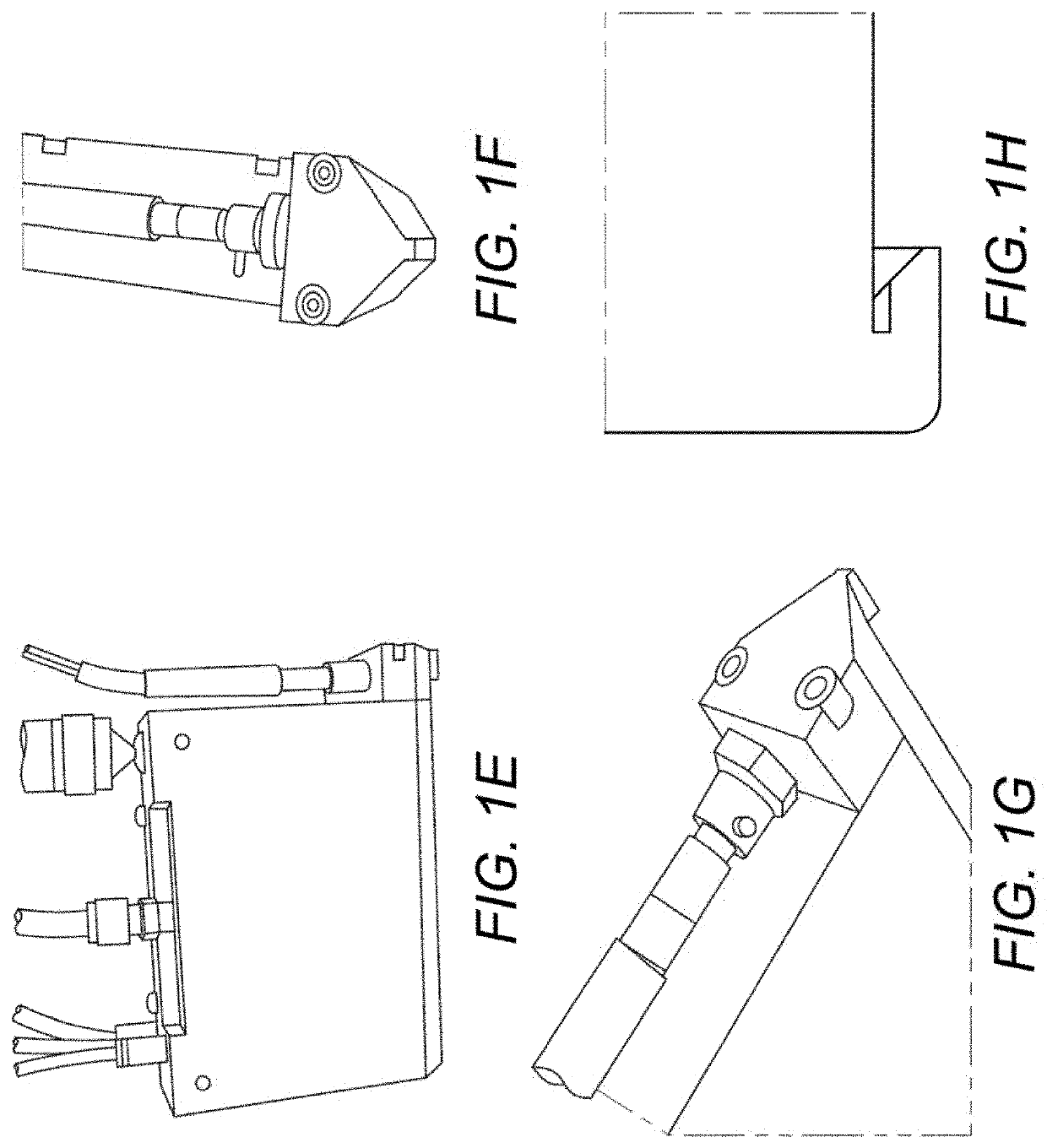

Method for forming crystal silicon film

InactiveCN102103989AReduce processing timeReduce manufacturing costFinal product manufactureSemiconductor/solid-state device manufacturingHydrogenMicrocrystalline silicon

The invention provides a method for forming a crystal silicon film. The method comprises the following steps: providing a substrate, and forming a first silicon structure film (such as a noncrystalline silicon film) on the substrate; modifying the first silicon structure film to form a seed crystal layer, wherein the modification comprises a hydrogen plasma processing and a helium plasma processing; and directly forming a second silicon structure film (such as a microcrystalline silicon film) on the seed crystal layer. The method has the advantages of lower cost and higher quality due to the modification comprising the hydrogen plasma processing and the helium plasma processing.

Owner:华映视讯(吴江)有限公司 +1

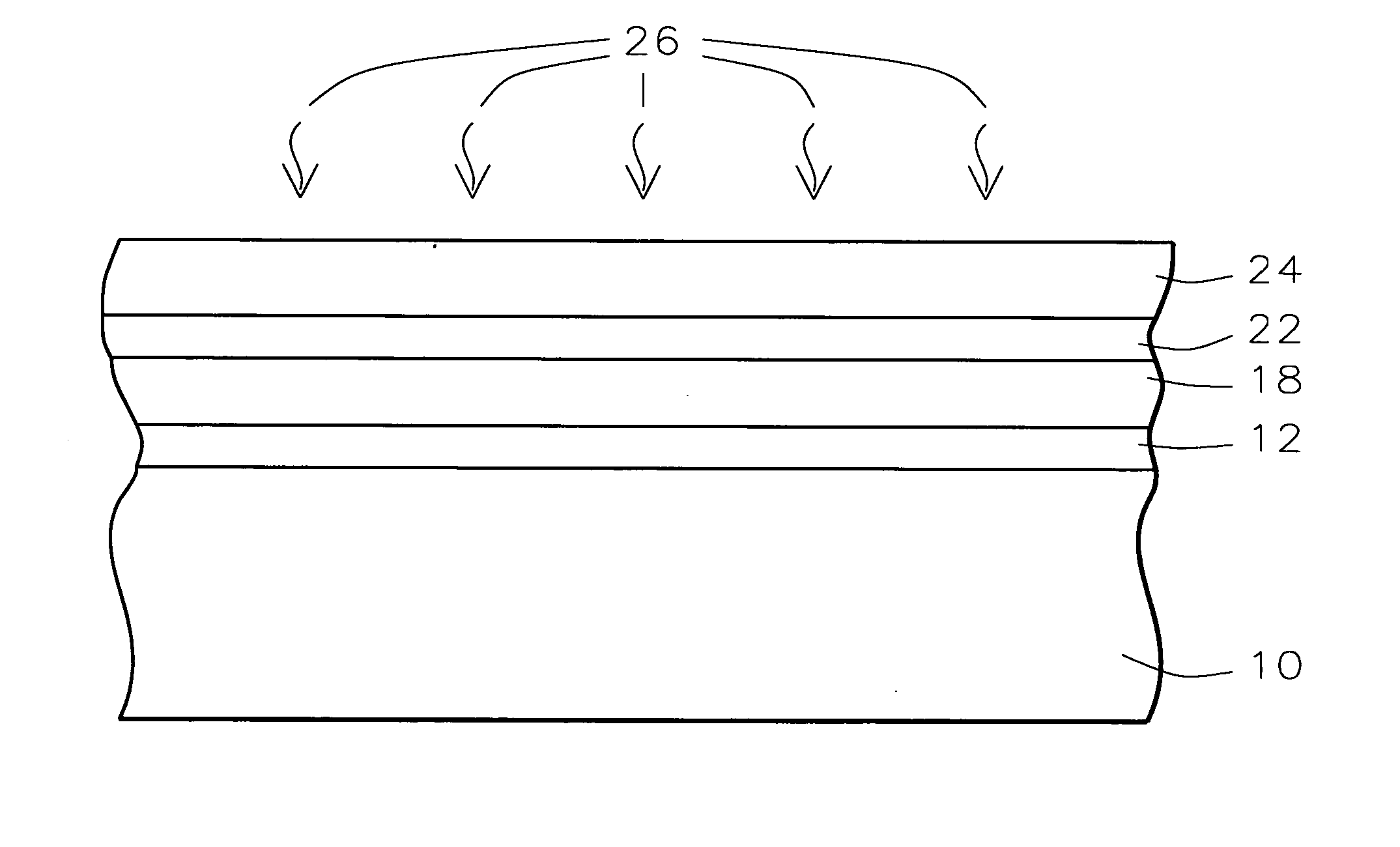

Semiconductor device manufacturing method

InactiveCN102290351AHigh hardnessNo increase in membrane stressSemiconductor/solid-state device manufacturingUV curingHardness

The invention discloses a method for manufacturing a semiconductor device, comprising: forming an insulating film containing silicon, oxygen and carbon on a semiconductor substrate by chemical vapor deposition; UV curing is performed on the insulating film being heated at a temperature of °C; and after the UV curing, helium plasma treatment is performed on the insulating film. The method provided by the invention can make the interlayer insulating film have high hardness without causing a large increase in film stress.

Owner:FUJITSU SEMICON LTD

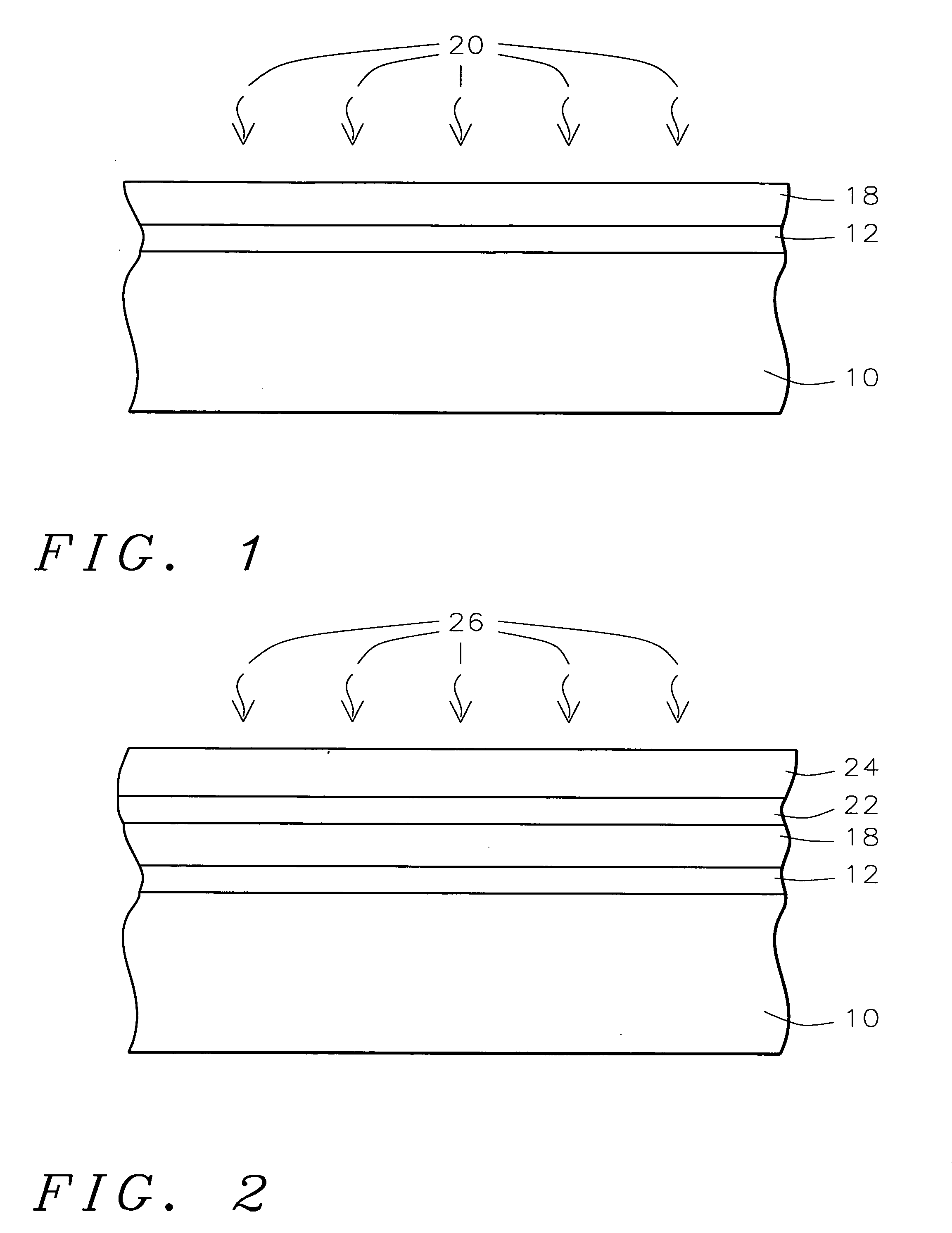

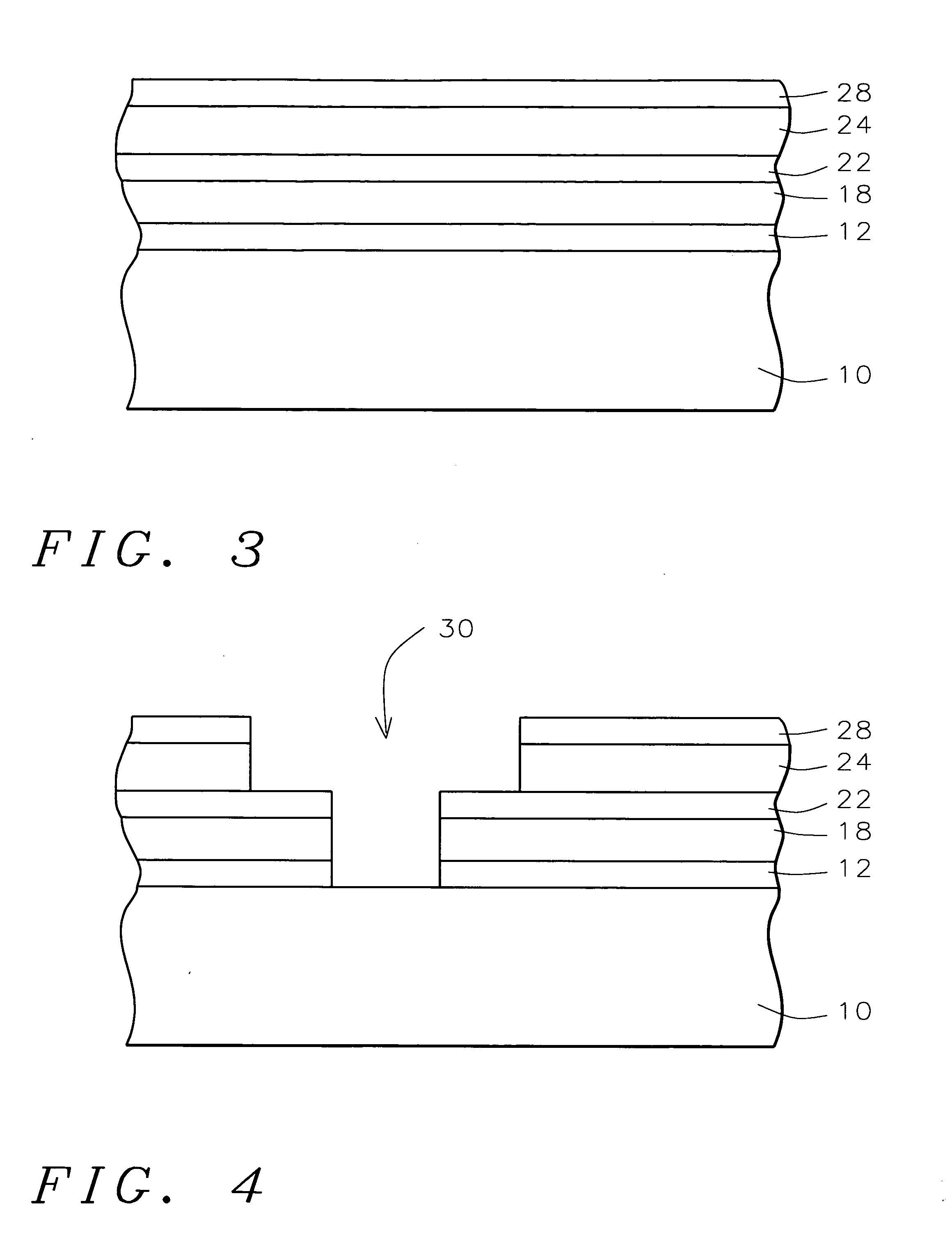

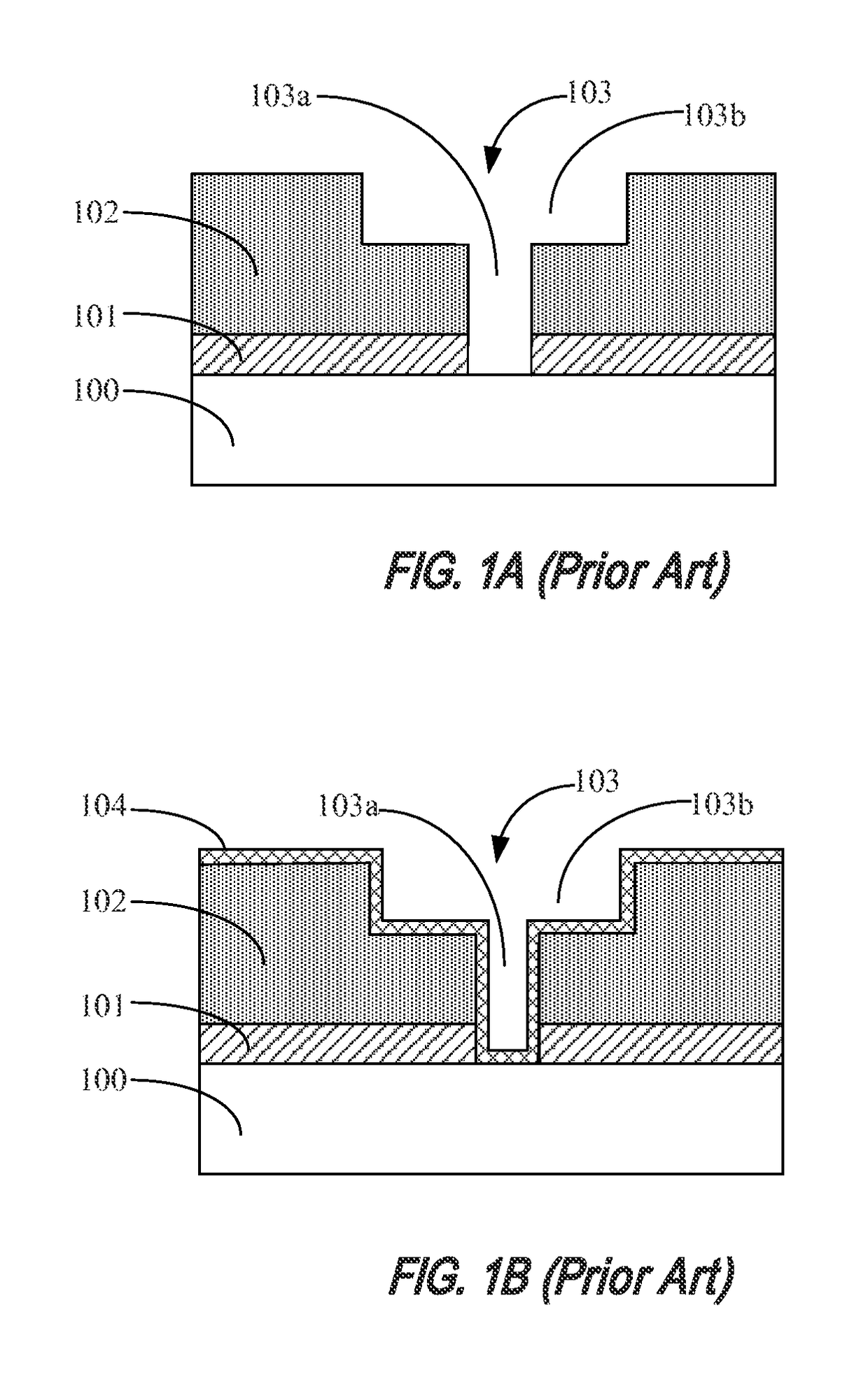

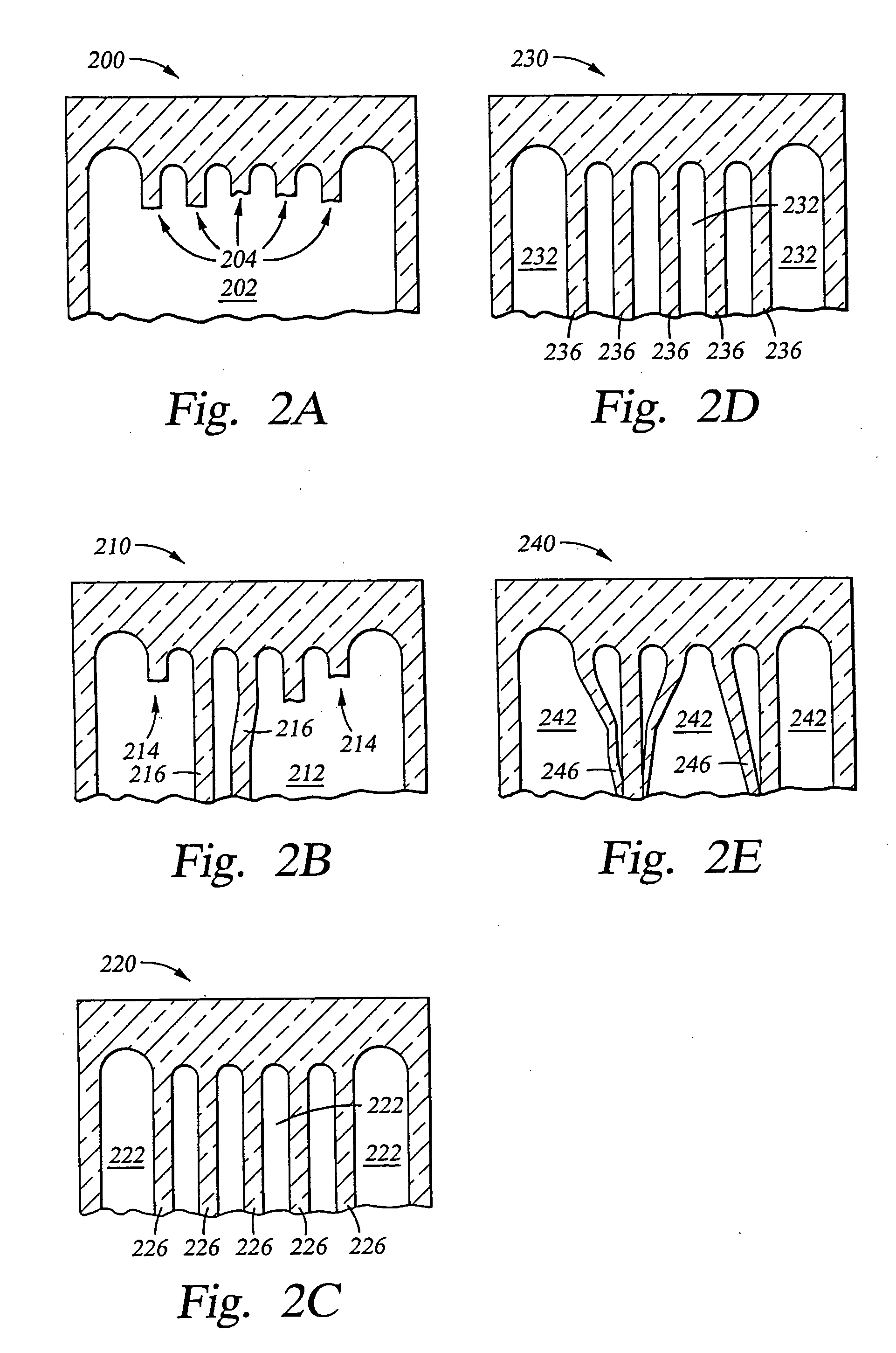

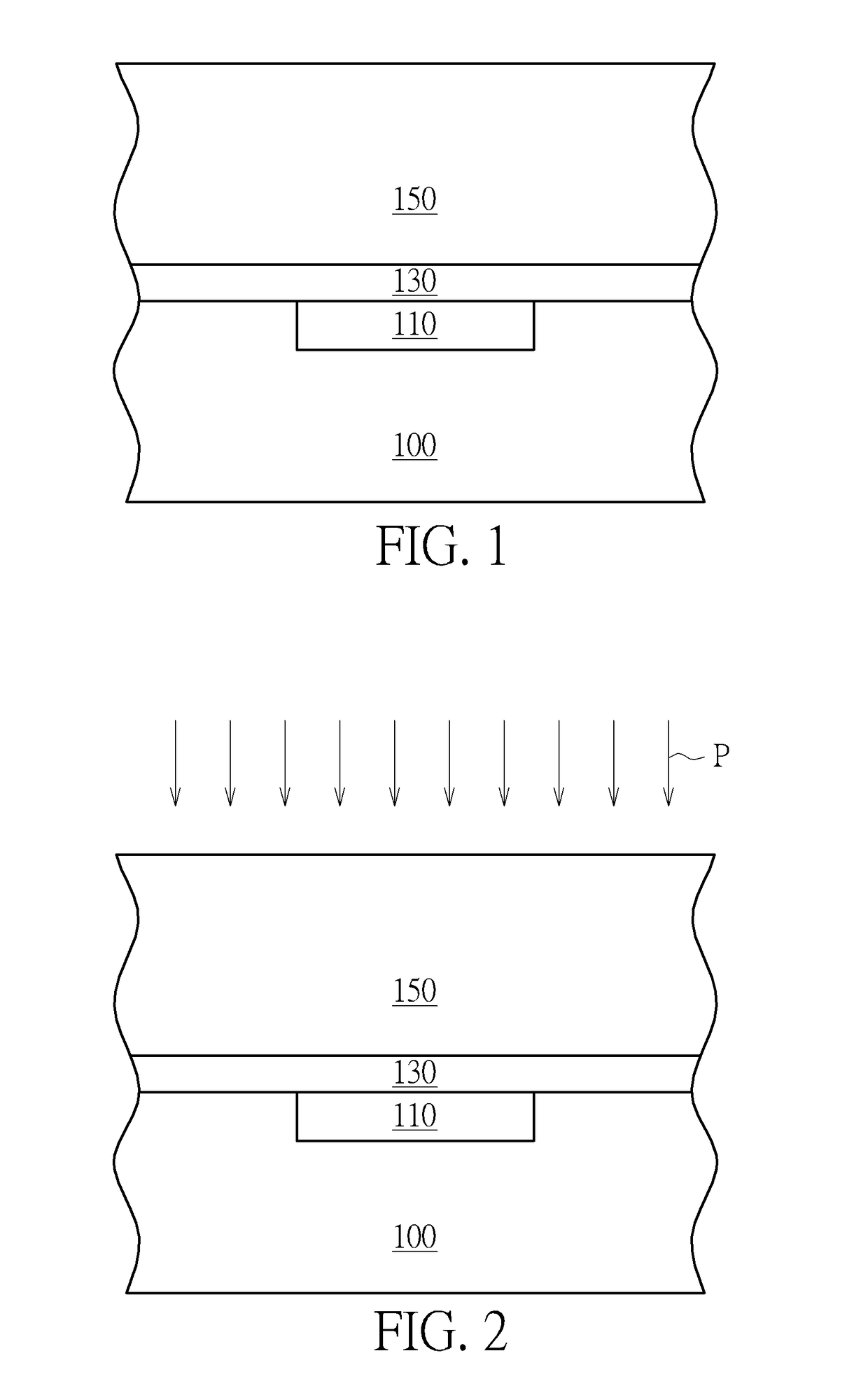

He treatment to improve low-K adhesion property

ActiveUS20050170663A1Improve adhesionReduce adhesionSemiconductor/solid-state device manufacturingOptoelectronicsHelium plasma

A method of improving adhesion of low dielectric constant films to other dielectric films is described. A low dielectric constant material layer is deposited on a substrate. The low dielectric constant material layer is treated with helium plasma. An overlying layer is deposited on the low dielectric constant material layer wherein there is good adhesion between the low dielectric constant material layer and the overlying layer.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

Process for preparing nitrogen doped micropore titanium dioxide photocatalysis layer of visual light on base of titan and titan alloy

InactiveCN101307431AReduce weightNo falling offPhysical/chemical process catalystsVacuum evaporation coatingOxygen plasmaTitanium

The invention relates to a method for preparing a nitrogen doped microporous titania visible light photocatalysis layer on a titanium and titanium alloy substrate, which relates to a method for preparing the titania visible light photocatalysis layer. The method solves the problems that TiO2 photocatalysis materials prepared by the prior art can increase the throw weight of a space station and can fall off. The method is as follows: firstly, oxygen plasma ion injection treatment is performed on titanium and titanium alloy; secondly, helium plasma ion injection treatment is performed; thirdly, annealing treatment is performed; fourthly, argon plasma denudation is performed and the titanium and the titanium alloy with micropores formed on the surfaces are obtained; fifthly, nitrogen ion injection treatment is performed, namely the nitrogen doped microporous titania visible light photocatalysis layer is obtained by preparation on the titanium and titanium alloy substrate. The materials obtained by the method can not fall off and do not increase the throw weight of the space station.

Owner:HARBIN INST OF TECH

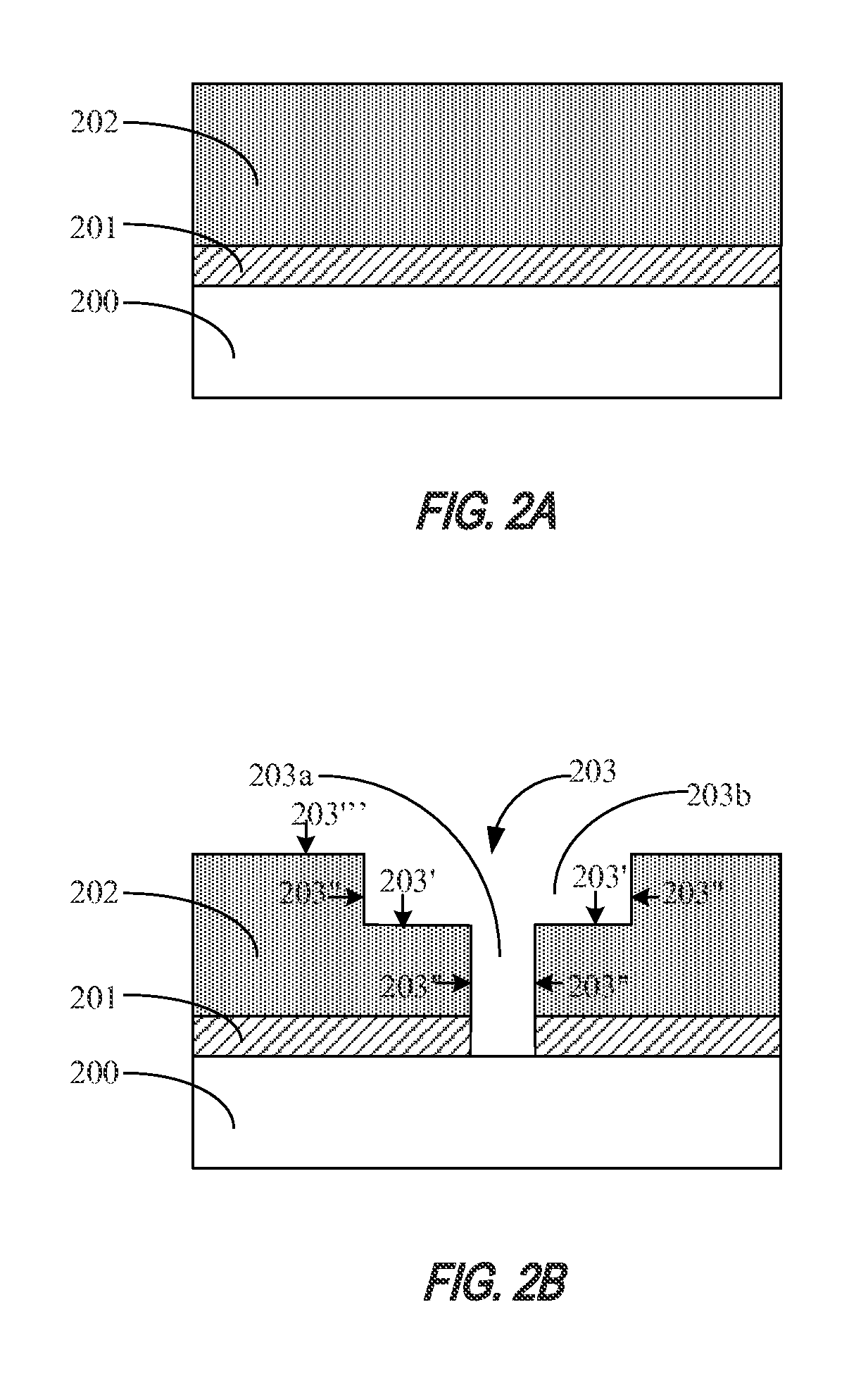

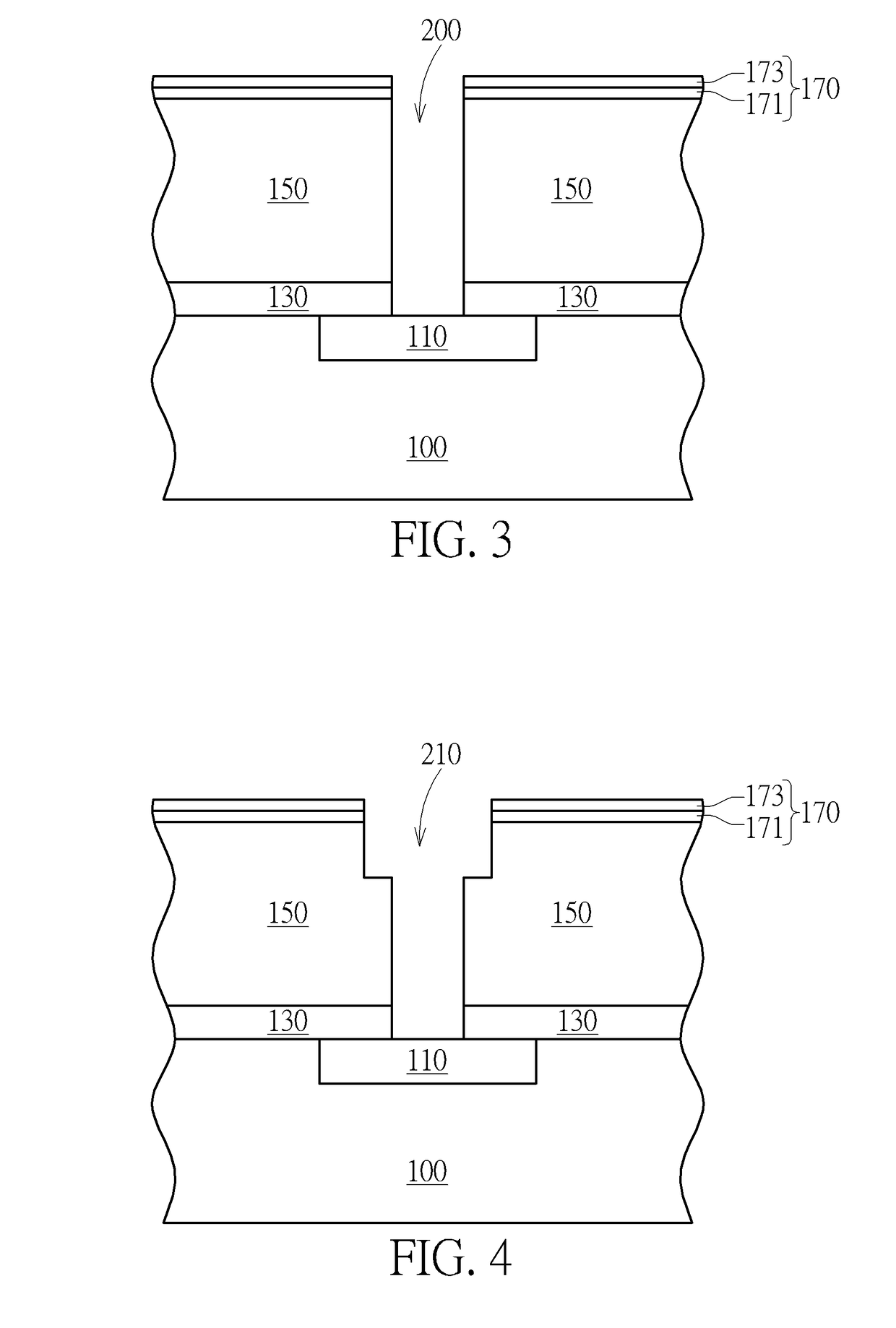

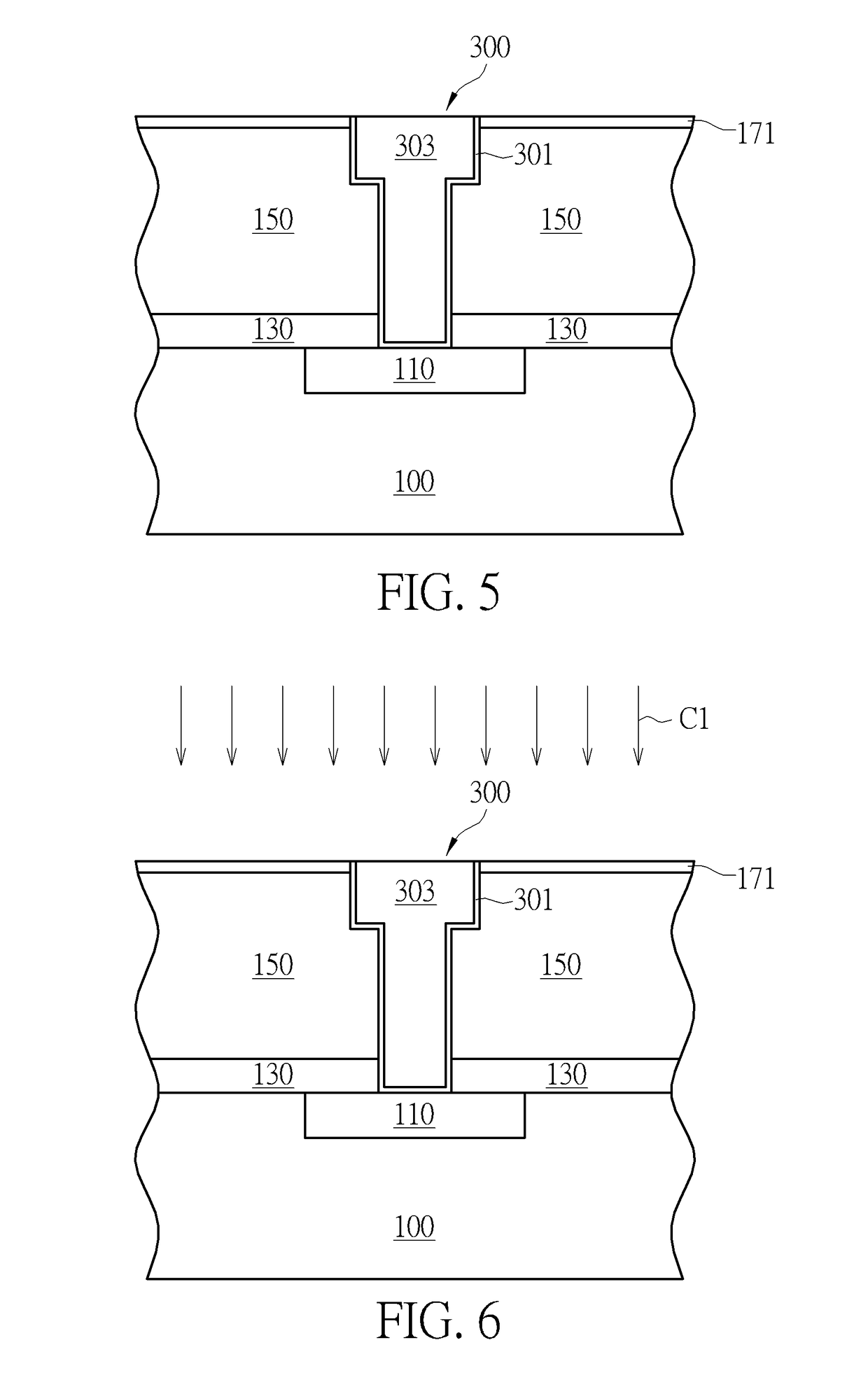

Method for improving adhesion between porous low k dielectric and barrier layer

ActiveUS9721892B2Semiconductor/solid-state device detailsSolid-state devicesNitrogen plasmaCopper interconnect

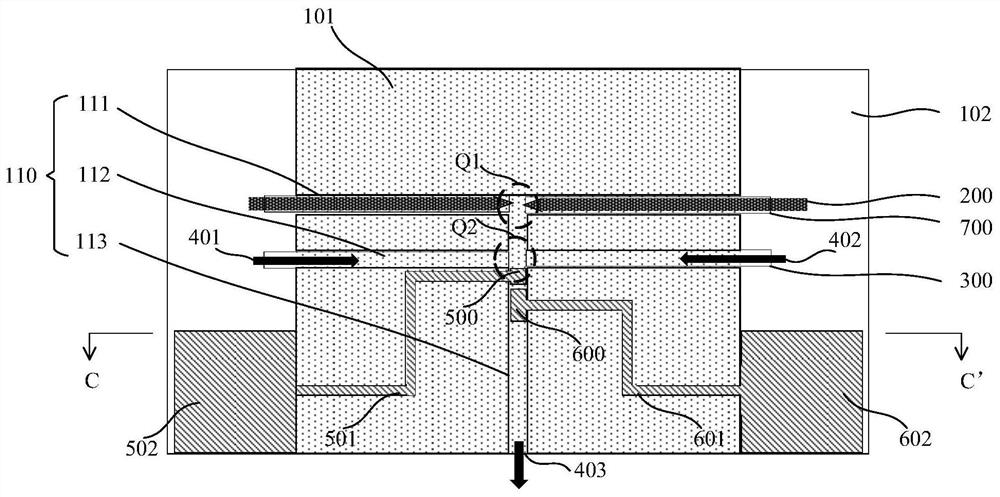

A semiconductor device and method for manufacturing the same are provided. The method includes providing a semiconductor substrate, forming a porous low-k dielectric layer on the semiconductor substrate, forming a through-hole and a trench of a copper interconnect structure, performing a helium plasma treatment on an exposed surface of the porous low-k dielectric layer, performing a nitrogen plasma treatment on the exposed surface of the porous low-k dielectric layer to form a silicon nitride layer, performing an argon plasma treatment on the silicon nitride layer, and forming a diffusion barrier layer on bottoms and sidewalls of the through-hole and the trench of the copper interconnect structure. Through the successive helium, nitrogen and argon plasma treatments, the low-k dielectric layer has a smooth and dense surface that increases the adhesion strength between the low-k dielectric layer and the diffusion barrier layer to improve reliability and yield of the semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Maintenance of photoresist activity on the surface of dielectric arcs for 90 nm feature sizes

InactiveUS20070117050A1Reduced footprintReduce the applied forcePhotoprinting processesSemiconductor/solid-state device manufacturingResistHydrogen

We have determined that it is necessary to remove hydroxyl groups from the surface of a DARC over which a CAR photoresist is applied, to reduce poisoning of the photoresist during imaging. The poisoning is reduced by treating the surface of the DARC film with a hydrogen or helium-containing plasma which is capable of removing the hydroxyl groups.

Owner:APPLIED MATERIALS INC

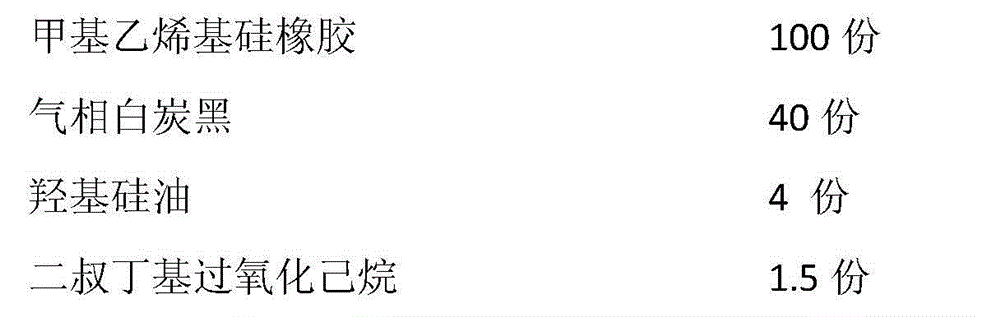

High-temperature-edible-oil-resistant silicone rubber blend and preparation method thereof

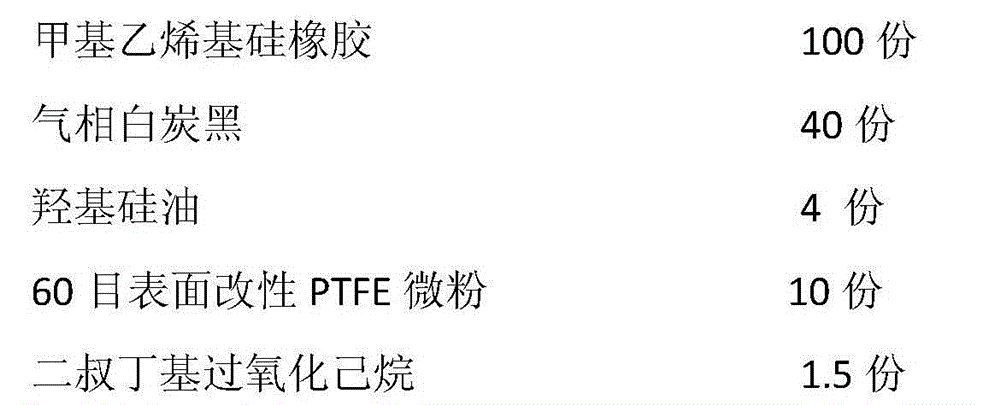

The invention discloses a high-temperature-edible-oil-resistant silicone rubber blend and a preparation method thereof. The blend comprises the raw materials of, by mass, 100 parts of silicone rubber, 40-60 parts of silica, 4-10 parts of silicone oil, 10-50 parts of surface-modified polytetrafluoroethylene (PTFE) micro-powder, and 1.5-5.0 parts of di-tert-butyl hexane peroxide. The surface-modified polytetrafluoroethylene micro-powder is obtained through the following steps: PTFE micro-powder is subjected to a surface photo-etching treatment by using a vacuum ultraviolet radiation source generated by helium plasma; and the etched PTFE micro-powder is exposed in the atmosphere for more than 10min, such that the surface-modified polytetrafluoroethylene micro-powder is obtained. The silicone rubber blend provided by the invention has high mechanical property retention rate in high-temperature edible oils. VOC discharge meets environment protection requirements. The blend has a simple preparation process, and is non-toxic and pollution-free. The blend can be used as a plastic or metal frame coating material of a high-temperature-edible-oil-resistant silicone rubber kitchenware product.

Owner:SOUTH CHINA UNIV OF TECH

Dentin bonding strength improving method

InactiveCN109431630AHigh bonding strengthTeeth fillingAdhesive processes with surface pretreatmentPlasma jetBond interface

The invention discloses a dentin bonding strength improving method. The dentin bonding strength improving method specifically comprises the following steps of, after tooth preparation is completed, etching the surface of dentin with etching agent for 15 seconds, then rinsing teeth with flowing water, wipe-drying the teeth, and spray-brushing the surface of the teeth through helium plasma jet flowfor 5 seconds, wherein the specific parameters of spray-brushing comprises regulating the input voltage of a high-voltage power source to be 20 V, current to be 0.6 A and helium flow to be 3L / min; moisturizing the surface of the teeth with a wet dust-free tissue, applying bonding agent, and after the bonding agent is cured for 10 seconds, piling resin. The dentin bonding strength improving methodcontrols the parameters of low-temperature and normal-pressure plasma production within the temperature range acceptable for the teeth, so that a bonding interface can be in contact with low-temperature and normal-pressure plasma jet flow continuously for a sufficient time period to achieve the effects of improving the bonding strength.

Owner:XIAN MEDICAL UNIV

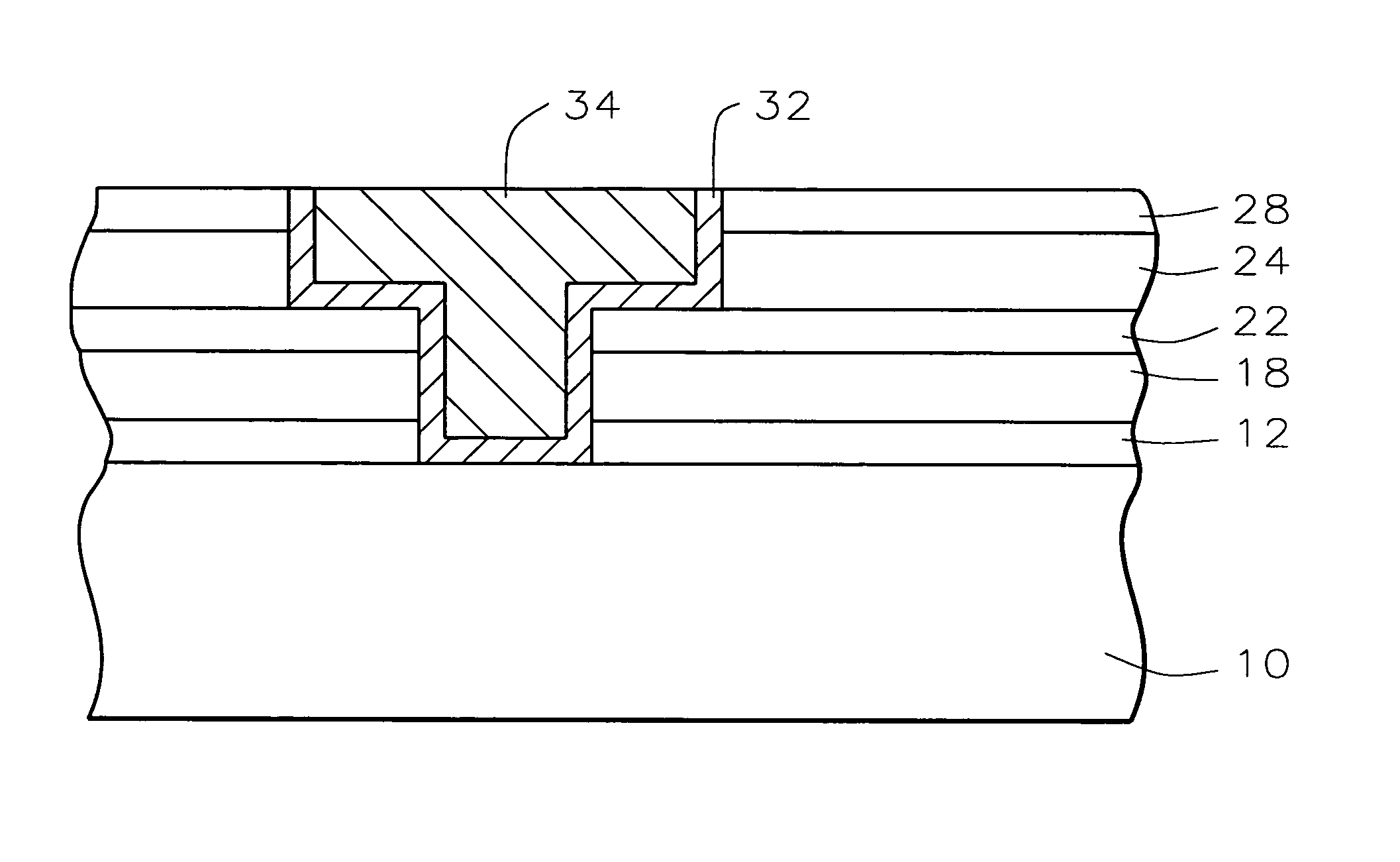

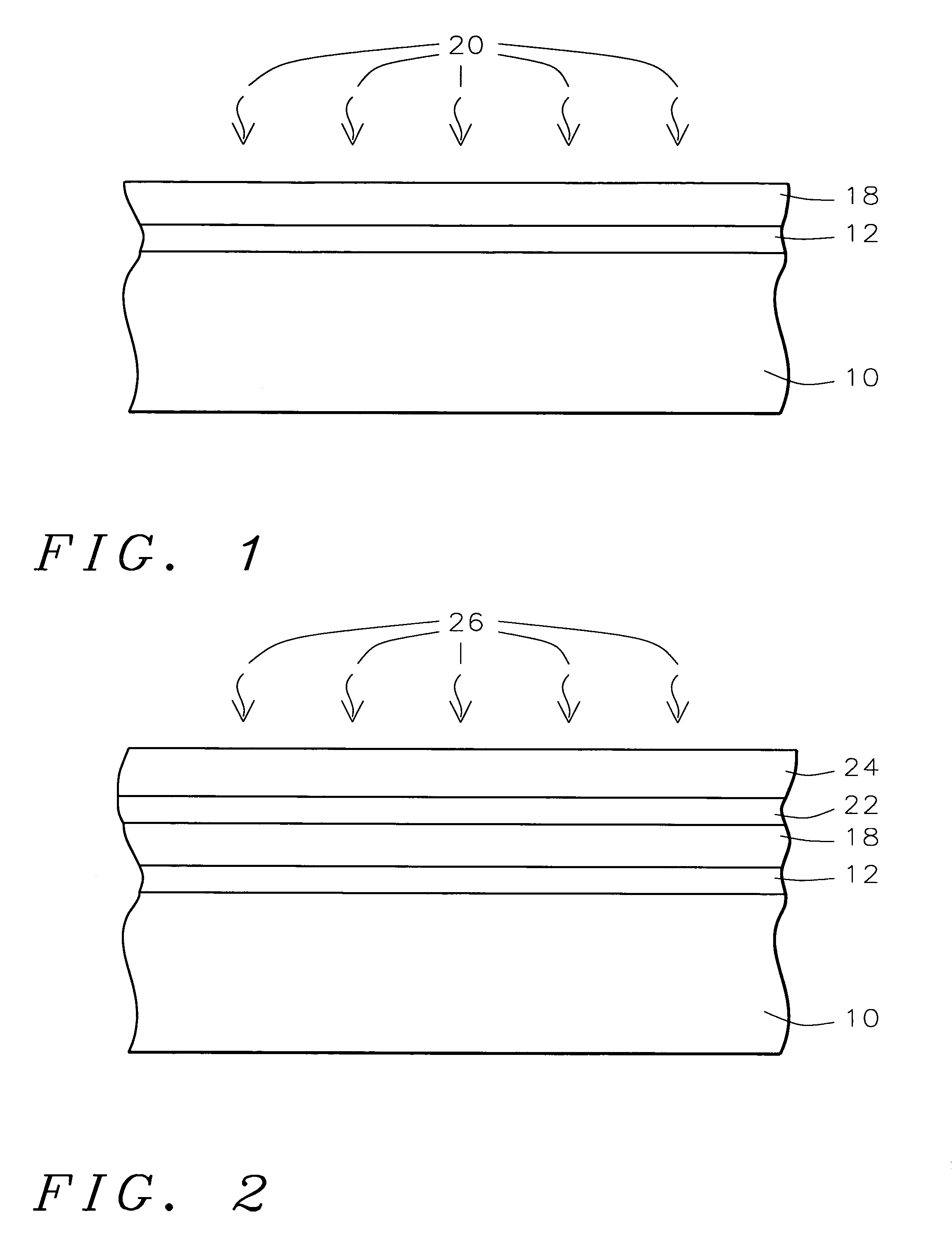

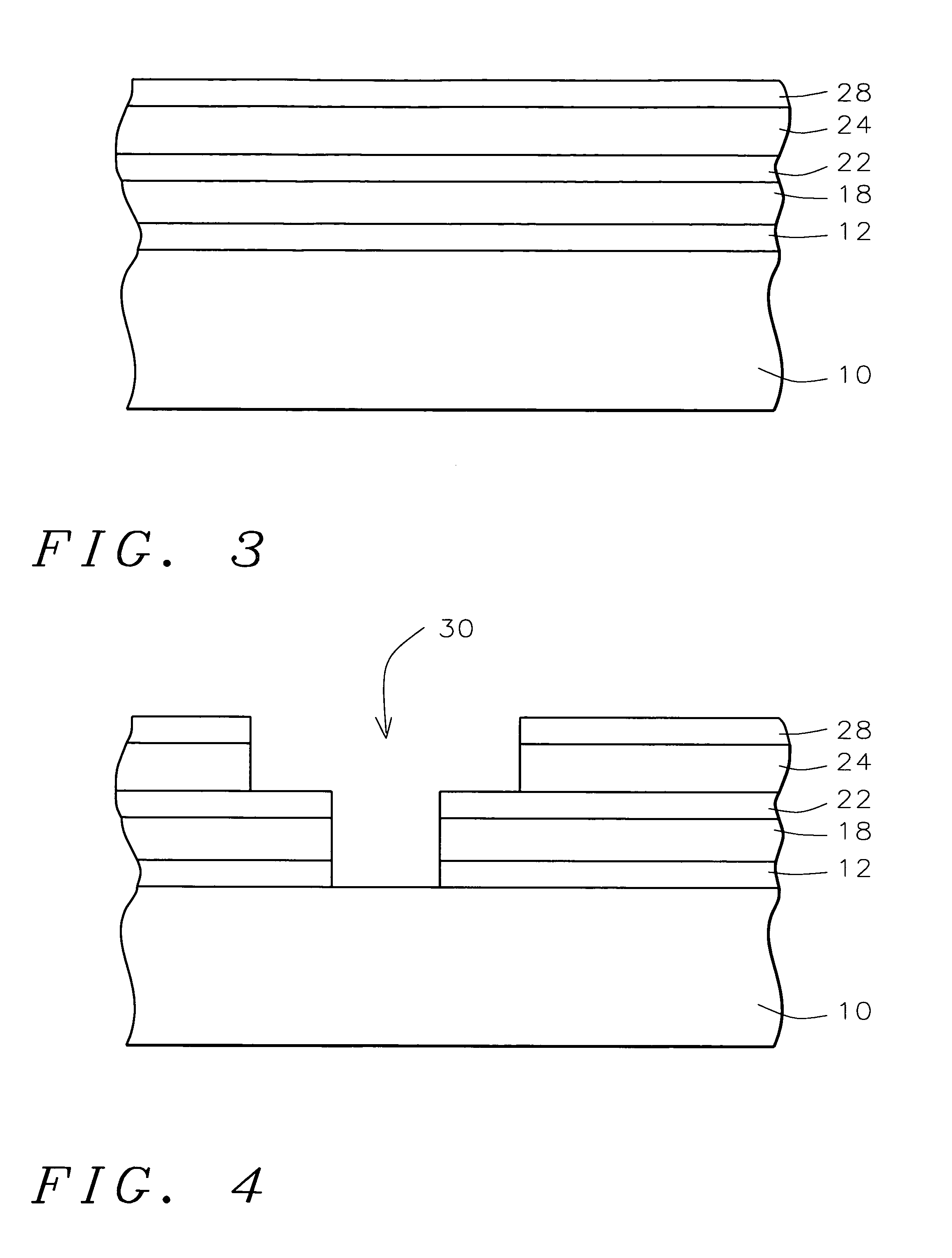

He treatment to improve low-k adhesion property

ActiveUS7144828B2Improve adhesionReduce adhesionSemiconductor/solid-state device manufacturingOptoelectronicsHelium plasma

A method of improving adhesion of low dielectric constant films to other dielectric films is described. A low dielectric constant material layer is deposited on a substrate. The low dielectric constant material layer is treated with helium plasma. An overlying layer is deposited on the low dielectric constant material layer wherein there is good adhesion between the low dielectric constant material layer and the overlying layer.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

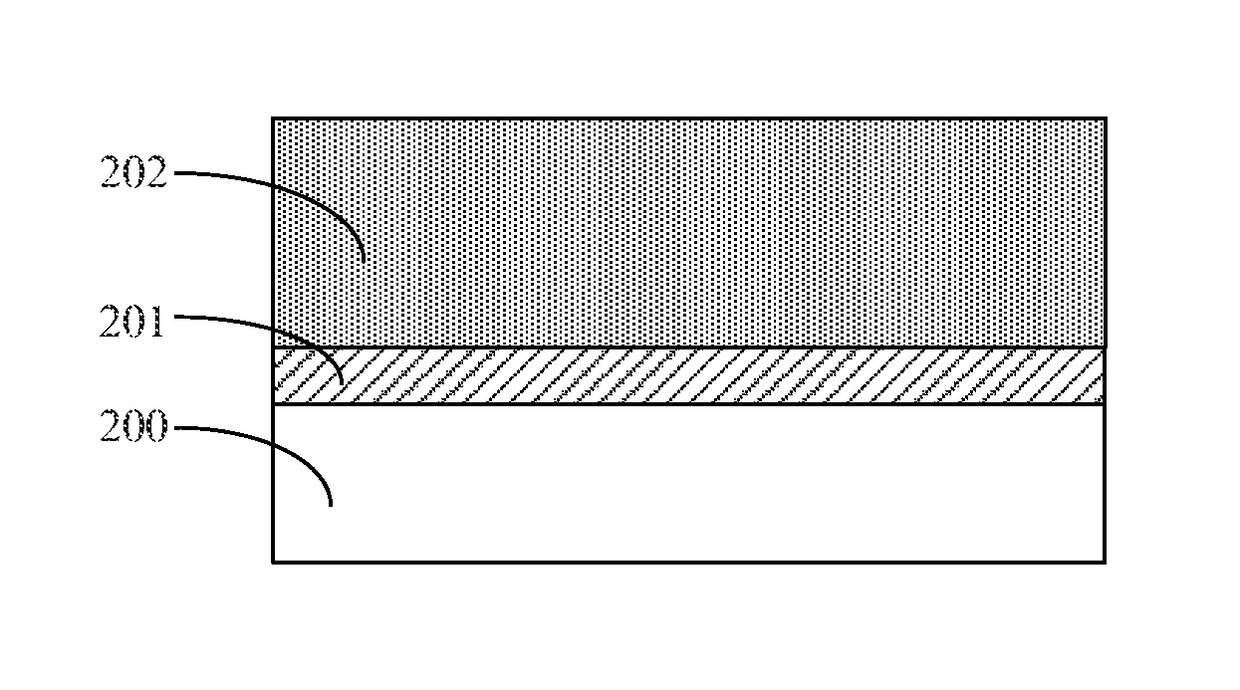

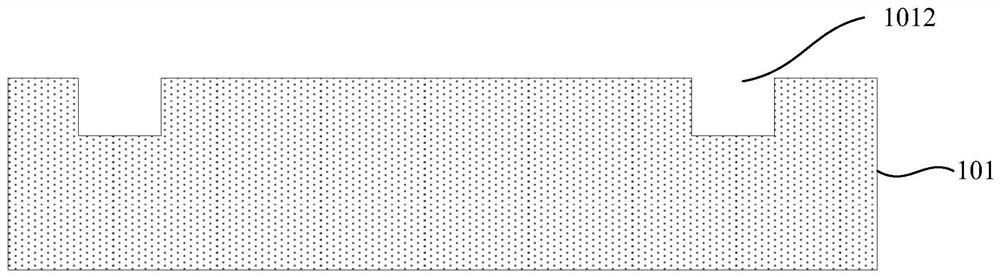

Low temperature formation of high quality silicon oxide films in semiconductor device manufacturing

ActiveCN109791870ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricDevice material

Silicon oxide layer is deposited on a semiconductor substrate by PECVD at a temperature of less than about 200 DEG C and is treated with helium plasma to reduce stress of the deposited layer to an absolute value of less than about 80 MPa. Plasma treatment reduces hydrogen content in the silicon oxide layer, and leads to low stress films that can also have high density and low roughness. In some embodiments, the film is deposited on a semiconductor substrate that contains one or more temperature-sensitive layers, such as layers of organic material or spin-on dielectric that cannot withstand temperatures of greater than 250 DEG C. In some embodiments the silicon oxide film is deposited to a thickness of between about 100-200 angstroms, and is used as a hard mask layer during etching of otherlayers on a semiconductor substrate.

Owner:LAM RES CORP

Passivation method of semiconductor device

ActiveCN112736641AUniform thicknessAvoid different thicknessesLaser detailsSemiconductor/solid-state device manufacturingDevice materialSemiconductor

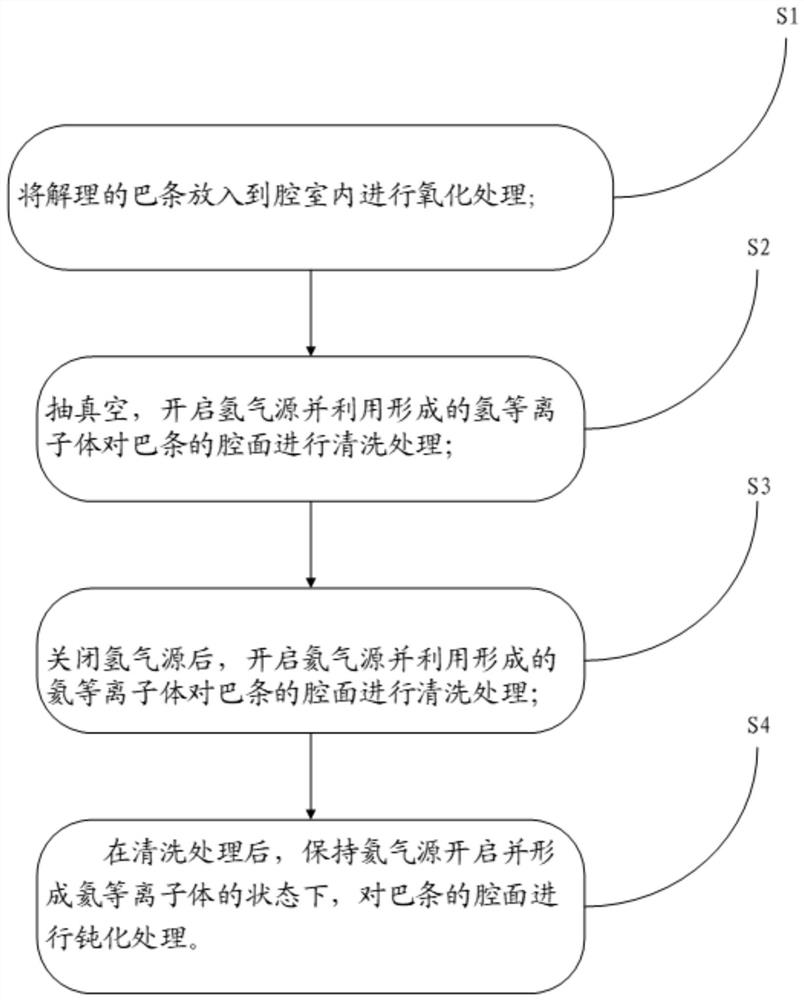

The invention provides a passivation method of a semiconductor device, and relates to the technical field related to semiconductors, and the passivation method of the semiconductor device comprises the following steps: putting a cleaved bar into a chamber for oxidation treatment; vacuumizing, cleaning the cavity surface of the bar by using the formed hydrogen plasma, and cleaning the cavity surface of the bar by using the formed helium plasma; after the cleaning treatment, under the state of keeping the helium source open and forming helium plasmas, carrying out passivation treatment on the cavity surface of the bar, and accelerating the passivation process. According to the passivation method of the semiconductor device provided by the invention, the naturally cleaved bar is subjected to oxidation treatment, so that the thickness of the oxide on the cavity surface of the bar is uniform, the problems of incomplete cleaning and over-cleaning in the cleaning process are avoided, and the cavity surface is sequentially cleaned by utilizing hydrogen plasma and helium plasma. Passivation is carried out when a helium source is started, and the oxide layer can be thoroughly cleaned and easily passivated.

Owner:度亘激光技术(苏州)有限公司

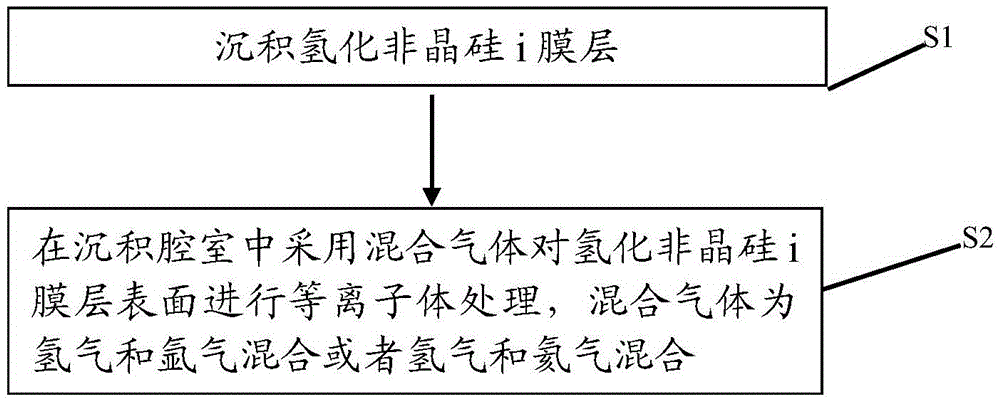

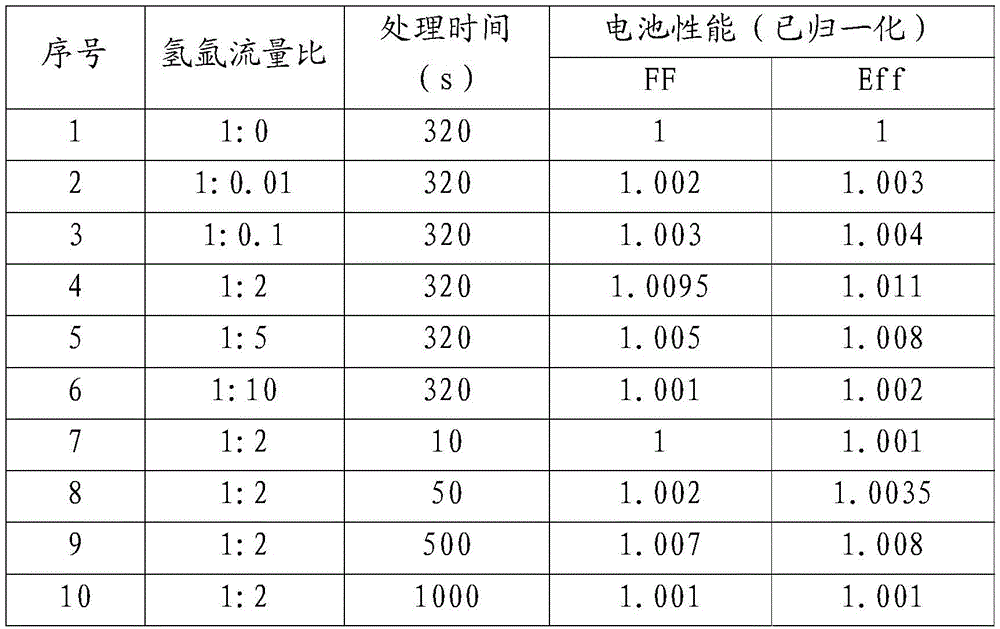

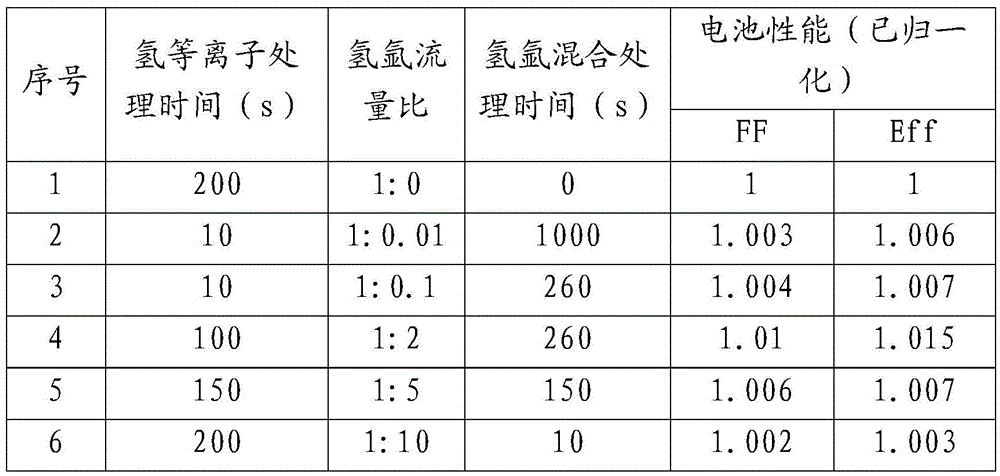

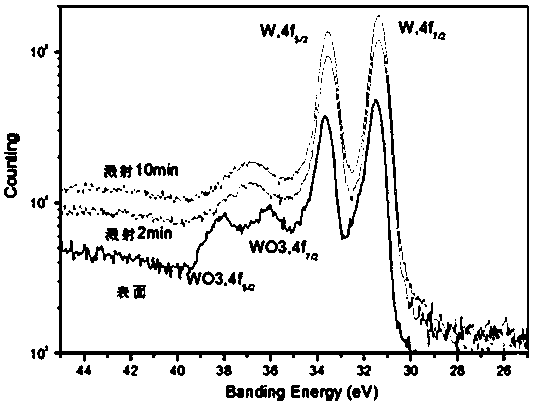

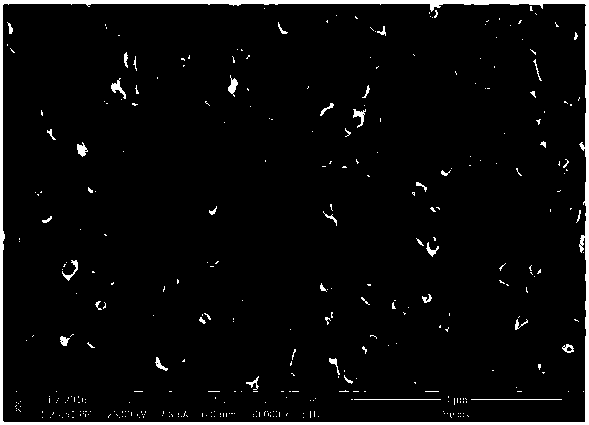

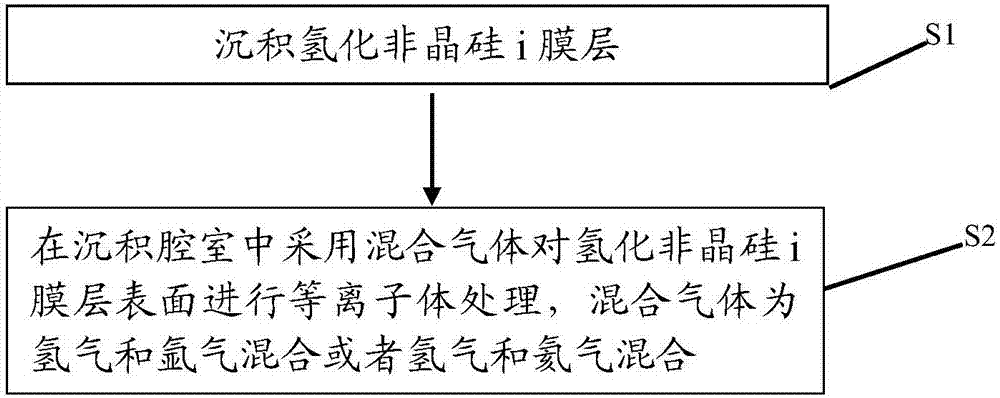

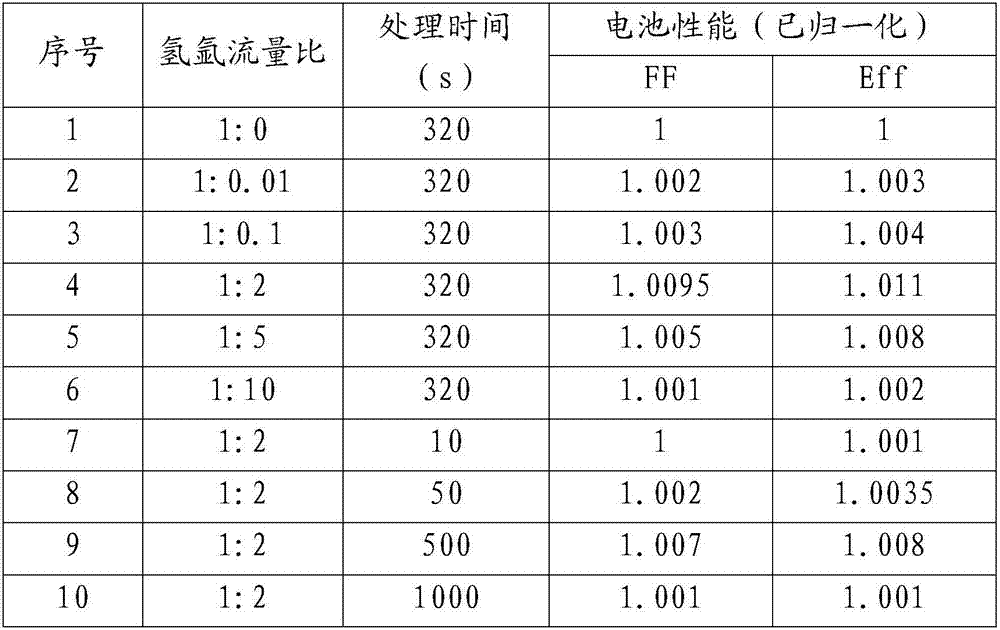

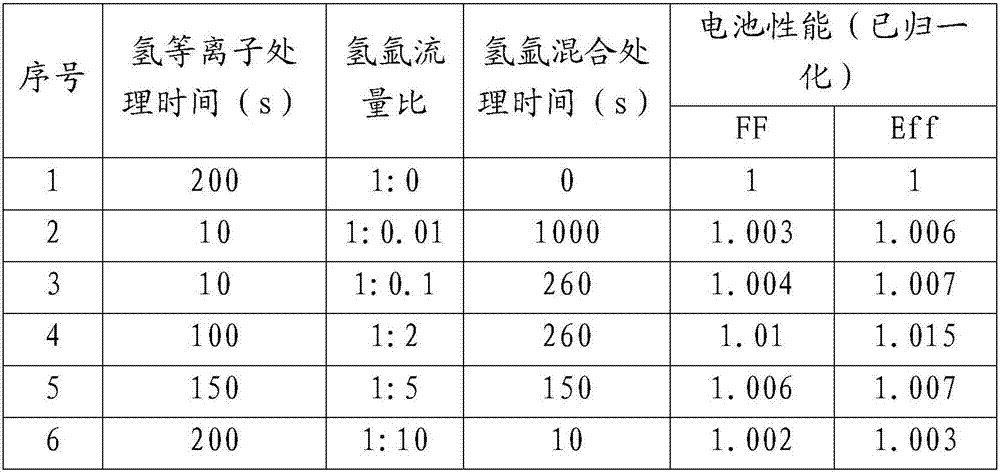

Solar cell and surface treatment method of hydrogenated amorphous silicon i film layer thereof

ActiveCN105489668AImprove performanceEasy to cleanFinal product manufacturePhotovoltaic energy generationHydrogenSolar cell

The invention discloses a silicon heterojunction solar cell and a surface treatment method of a hydrogenated amorphous silicon i film layer thereof. Plasma treatment is carried out on the surface of the hydrogenated amorphous silicon i film layer by adopting a gas mixture of hydrogen and argon or hydrogen and helium, the hydrogenated amorphous silicon i film layer can be preferably cleaned in a physical manner through argon or helium plasmas, and the increase of the amount of the helium plasmas is further promoted, so that the passivating and cleaning effects for the surface of the hydrogenated amorphous silicon i film layer are strengthened; and moreover, slight damage to the surface of the hydrogenated amorphous silicon i film layer can be generated in the physical bombarding process of the argon or helium plasmas, and the hydrogen plasmas can play a passivating role on the surface of the hydrogenated amorphous silicon i film layer and can also repair the slight damage. Through the synergistic effect of the gas mixture of hydrogen and argon or hydrogen and helium, better passivating and cleaning effects can be achieved for the surface of the hydrogenated amorphous silicon i film layer, so that the battery performance is promoted.

Owner:ENN SOLAR ENERGY

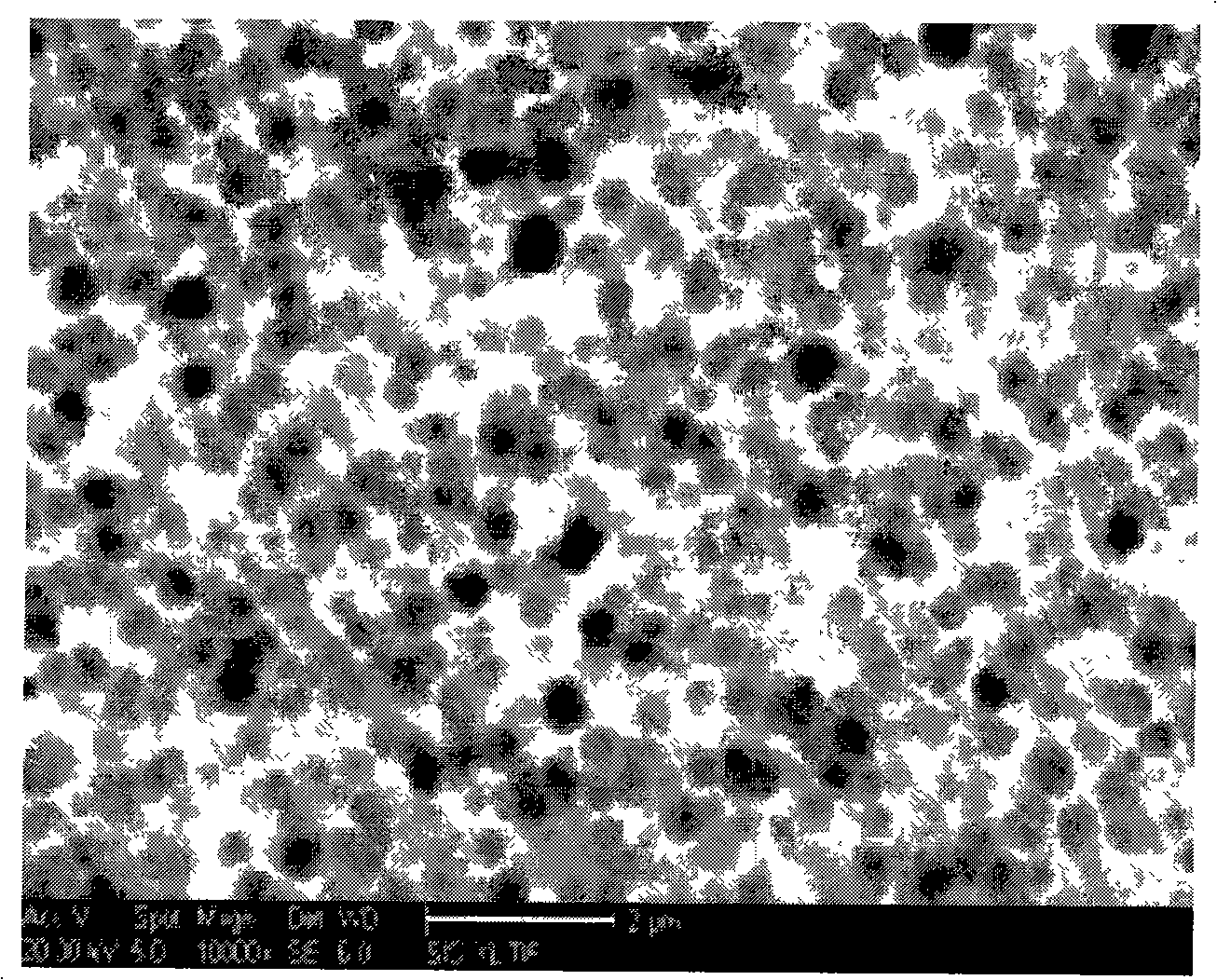

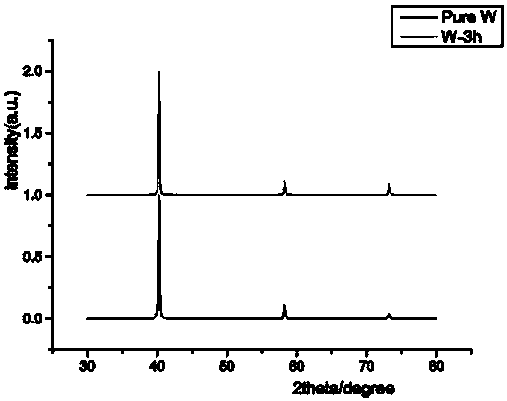

Metal tungsten surface nanocrystallization device and method thereof

ActiveCN108456854ASimple structureLow costMaterial nanotechnologyVacuum evaporation coatingPower flowDecomposition

The invention discloses a metal tungsten surface nanocrystallization device and a method thereof. The method comprises the following steps: taking a tungsten cylinder provided with small holes as a hollow cathode device to form a hollow cathode effect, ionizing helium gas to obtain low-voltage and high-current helium plasma, enabling the helium ions to carry out bombardment action on the surface of a tungsten sample, rapidly increasing the temperature of the sample to be higher than 1600K in 5 minutes through the hollow cathode effect, injecting a certain quantity of helium ions, then obtaining a nanostructure in tight connection with a matrix on the tungsten surface. According to the metal tungsten surface nanocrystallization device and the method thereof, the device is simple and convenient, is low in cost, simple in process and high in production efficiency, and is capable of forming uniform and consistent nanostructure growth layers in tight connection with the matrix on the surface of the metal tungsten; a new method for solving nanocrystallization of the tungsten surface is provided; the products can be further treated to obtain photocatalytic materials for preparing decomposition water.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Solar cell and hydrogenated amorphous silicon i membrane surface processing method thereof

ActiveCN107425087AImprove performanceEasy to cleanFinal product manufacturePhotovoltaic energy generationHydrogenPhysical chemistry

Owner:ENN SOLAR ENERGY

Method of forming semiconductor device

InactiveUS20180350663A1High yieldQuality improvementSemiconductor/solid-state device manufacturingDielectric layerSemiconductor

The present invention provides a method of forming a semiconductor device including the following steps. First of all, a dielectric layer is formed, and a helium plasma treatment is performed on the dielectric layer. Next, an acid cleaning process is performed on a surface of the dielectric layer after performing the helium plasma treatment. Then, an alkaline brushing process is performed on the surface.

Owner:UNITED MICROELECTRONICS CORP

Method for determining helium concentration depth distribution in metal material by using radio frequency glow discharge spectrometer

PendingCN111562253AQuick checkQuick calibrationAnalysis by electrical excitationMetallic materialsParticle physics

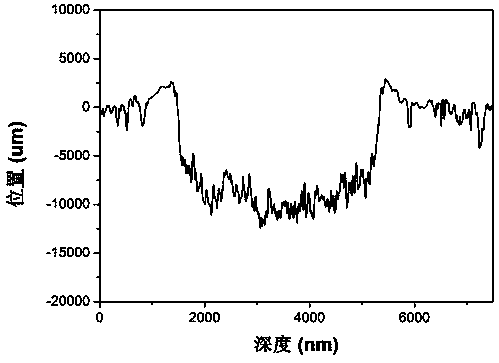

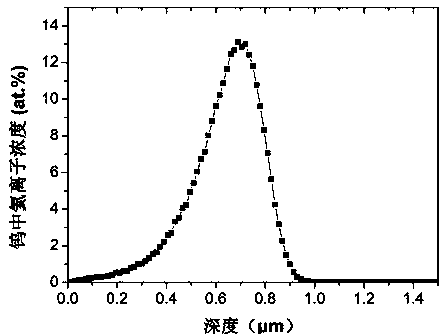

The invention provides a method for measuring helium concentration distribution in a metal material by a radio frequency glow discharge spectrometer. The method includes: preparing a helium-containingtungsten material as a standard sample through high-energy helium ion implantation, conducting SRIM software simulation calculation to obtain concentration distribution information of helium in the tungsten material, setting the working conditions of a radio frequency glow discharge spectrometer, carrying out glow discharge spectrum detection in the depth direction on the standard sample, and calibrating the relation between the etching depth and the test duration of the standard sample by a non-contact optical profilometer; combining an SRIM simulation result and the etching depth-time relationship, converting an electric signal curve of the detected helium into helium concentration depth distribution information; and finally, detecting the copper and EUROFER steel samples irradiated byhelium plasmas by using a radio frequency glow discharge spectrometry so as to verify the feasibility and accuracy of the method. The method can provide a rapid, quantitative and reliable detection and analysis method for retention of helium in a plasma-oriented material for a magnetic confinement nuclear fusion Tokamak device.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

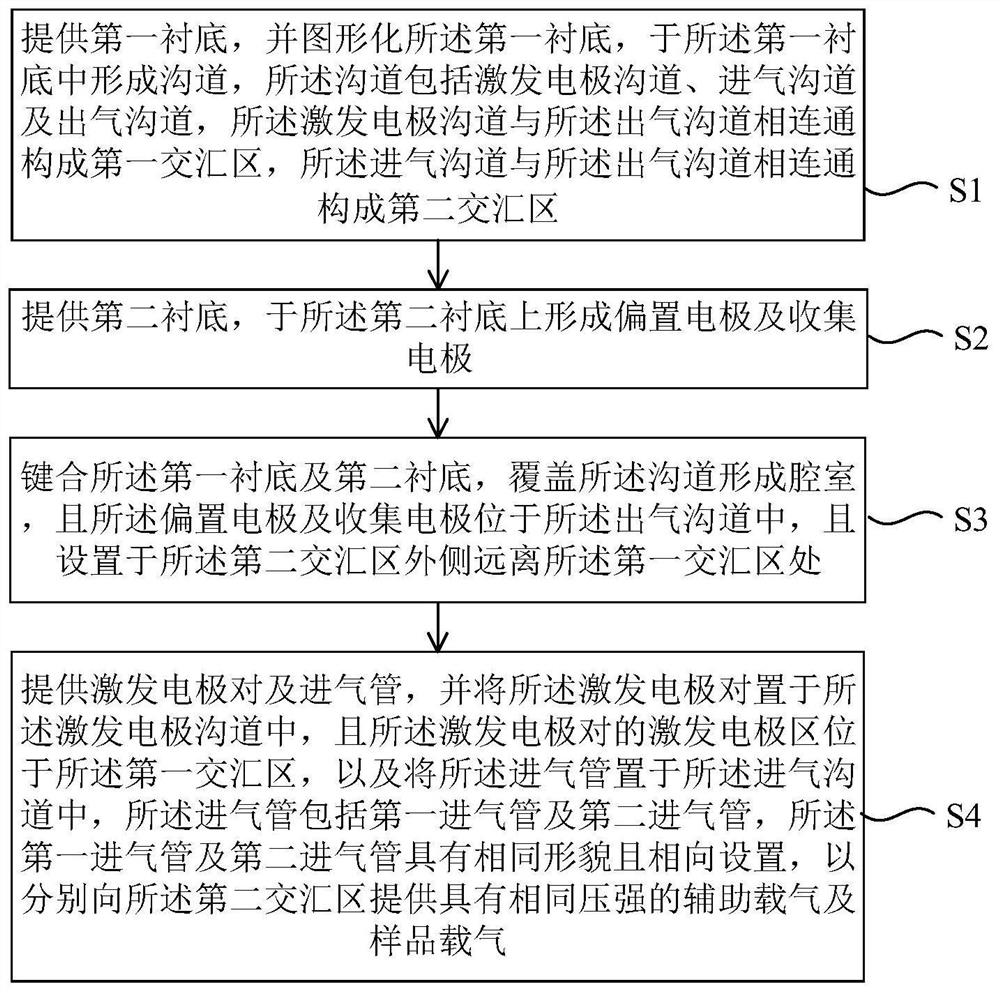

Helium ionization detector and preparation method thereof

PendingCN113311096AHigh densityReduce noiseComponent separationHelium ionization detectorHelium ions

The invention provides a helium ionization detector and a preparation method thereof. The helium ionization detector comprises a substrate, an excitation electrode pair, gas inlet pipes, a bias electrode and a collection electrode; a cavity is formed in the substrate, the cavity comprises an excitation electrode channel, an air inlet channel and an air outlet channel, the excitation electrode channel and the air outlet channel are communicated to form a first intersection area, and the air inlet channel and the air outlet channel are communicated to form a second intersection area; an excitation electrode region of the excitation electrode pair is positioned in the first intersection area; the gas inlet pipes are a first gas inlet pipe and a second gas inlet pipe which have the same morphology and are oppositely arranged, and can provide auxiliary carrier gas and sample carrier gas with the same pressure intensity for the second intersection area; the bias electrode and the collection electrode are located in the air outlet channel and arranged on the outer side of the second intersection area away from the first intersection area. According to the invention, a high-pressure quasi-zero flow velocity region can be formed in the cavity, helium plasma excitation is facilitated, the helium flow velocity in the area is extremely low, helium plasma groups can be stabilized, and then baseline noise can be reduced.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

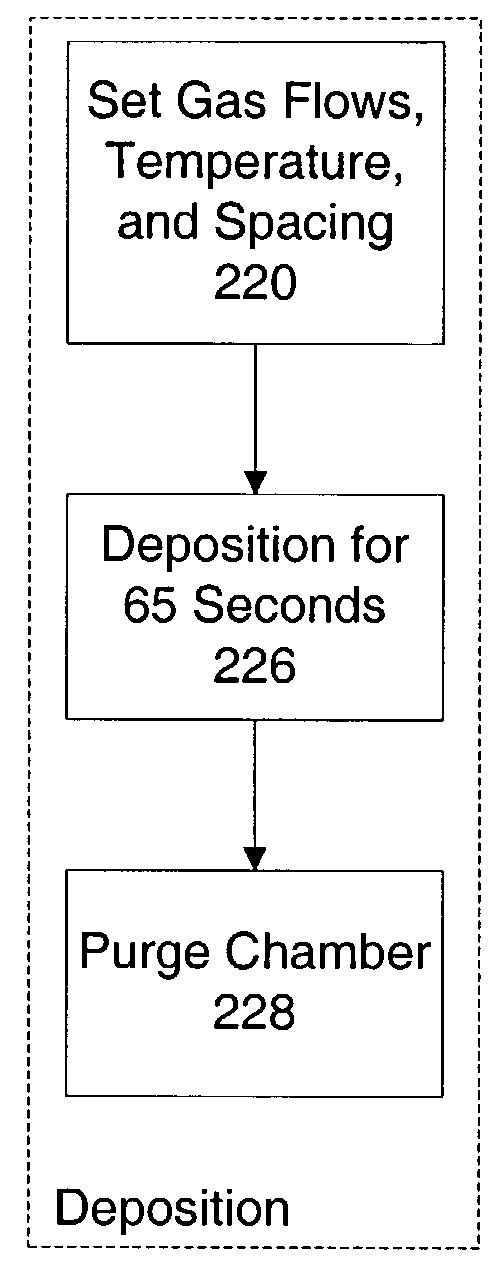

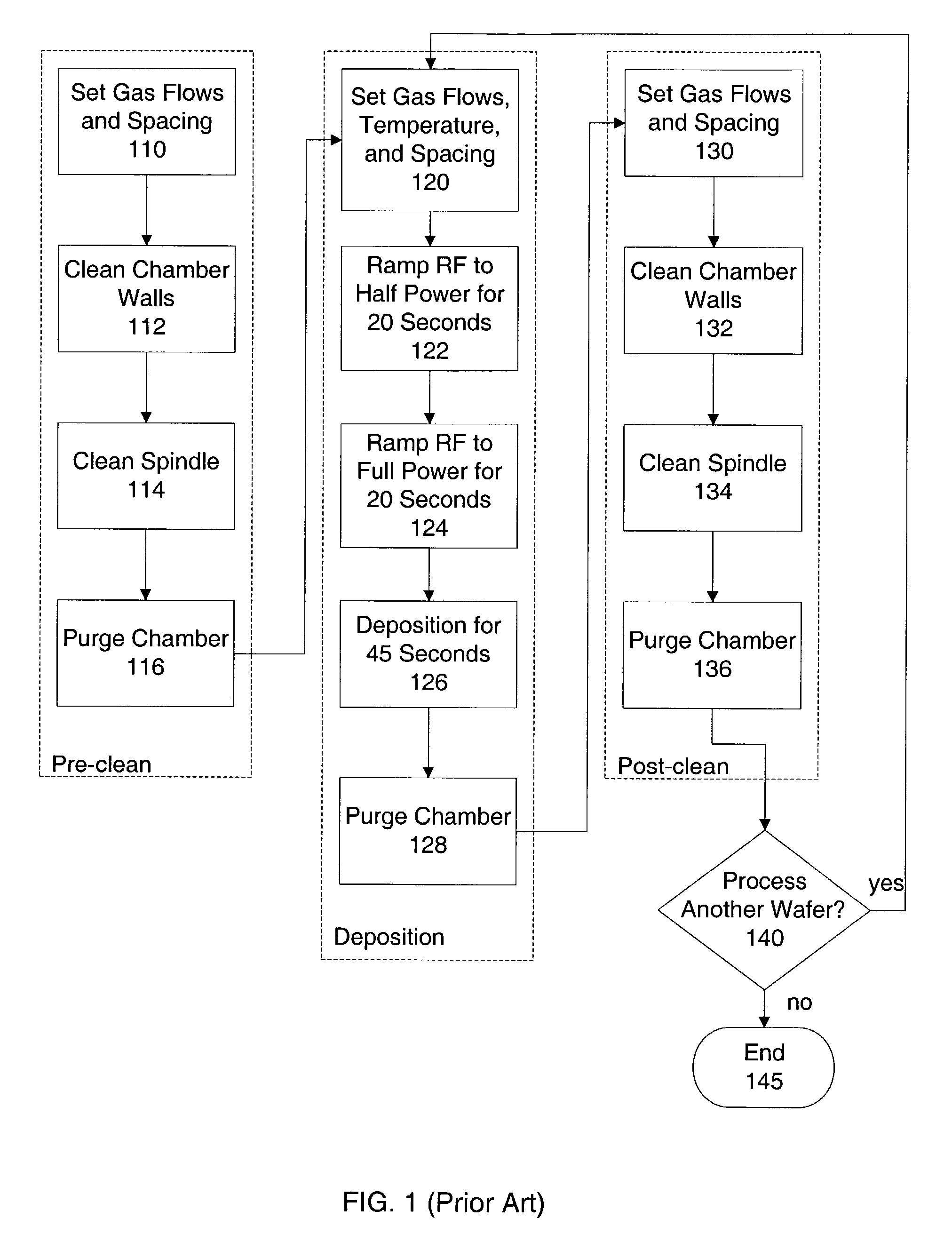

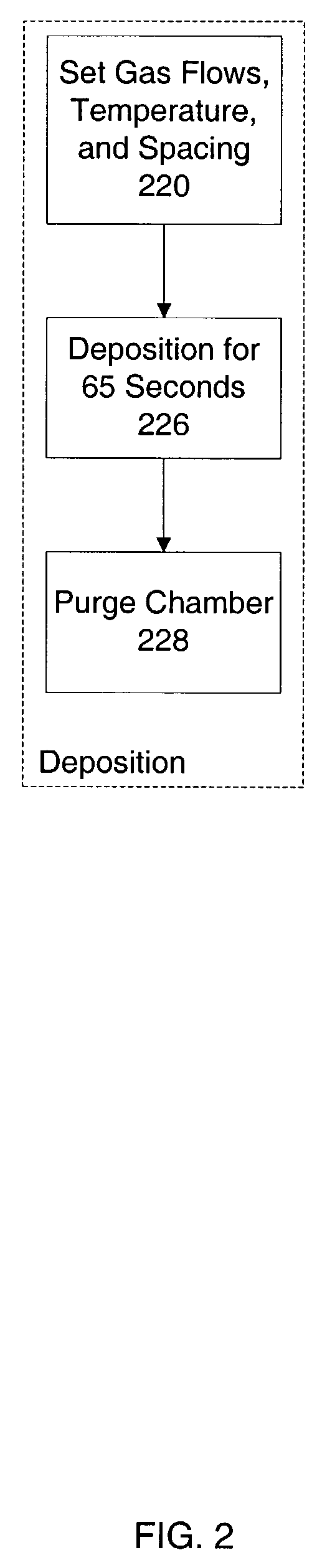

Chemical vapor deposition chamber pre-deposition treatment for improved carbon doped oxide thickness uniformity and throughput

InactiveUS7125583B2Improve throughputImprove uniformityHollow article cleaningElectrostatic cleaningDeposition processChemical vapor deposition

A method for improving thickness uniformity and throughput of a carbon doped oxide deposition process is described. That method comprises removing pre-deposition steps in a deposition phase. Moreover, helium plasma is added to a pre-clean phase to eliminate the production of dummy wafers.

Owner:INTEL CORP

Post treatment methods for oxide layers on semiconductor devices

ActiveUS9431237B2Slow changeInterfaceSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceHydrogen

Methods and apparatus for post treating an oxide layer on a semiconductor substrate are disclosed. In one or more embodiments, the oxide layer is formed by thermal oxidation or plasma oxidation and treated with a plasma comprising helium. The helium-containing plasma may also include hydrogen, neon, argon and combinations thereof. In one or more embodiments, a SiO2 oxide layer is formed on a silicon substrate and treated with a plasma to improve the interface between the silicon substrate and the SiO2 oxide layer.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com