Wide-range flexible resistance type pressure sensor and preparation method thereof

A resistive pressure and sensor technology, applied in the measurement of force, electric solid devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem that the measurement range is not as good as that of composite sponge, the synthesis process of porous structure is complicated, and the practical application is restricted. and commercialization, to achieve the effect of increasing the effective contact area, good linear response, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

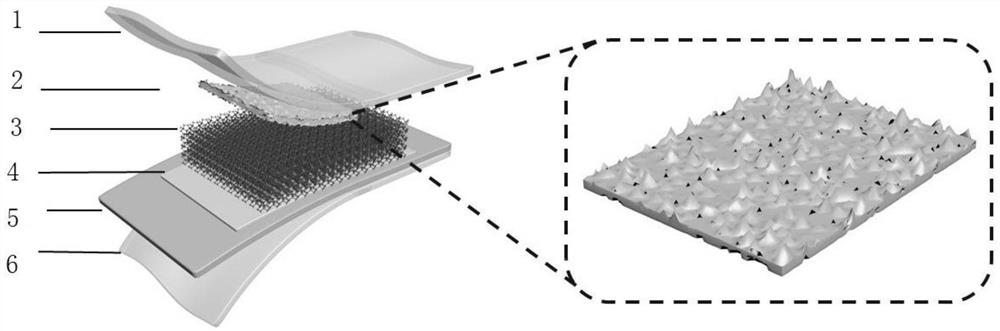

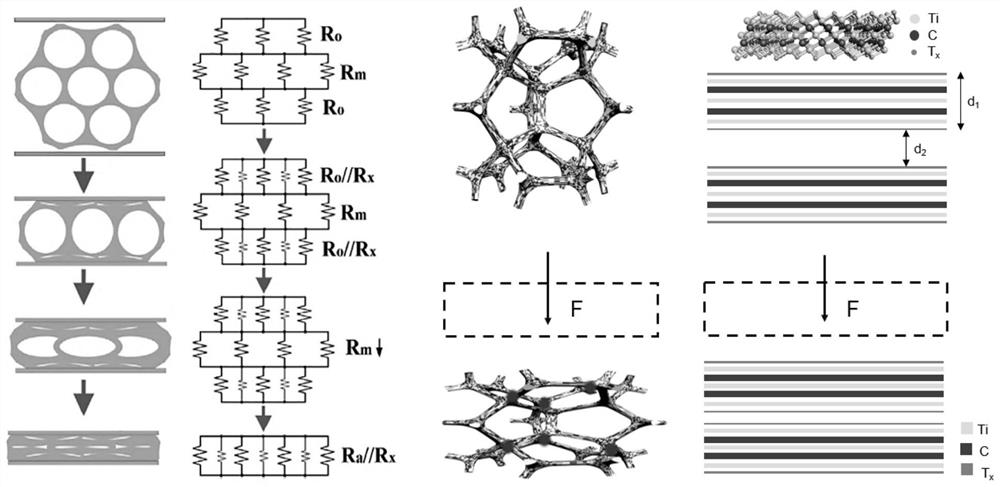

[0039] like figure 1 As shown, a wide-range flexible resistive pressure sensor, the sensor is a multi-layer structure, from bottom to top are the lower packaging layer 6, the flexible base layer 5, the first conductive electrode 4, the composite sponge layer 3, the second conductive electrode 2 , the upper packaging layer 1; one side of the second conductive electrode 2 has a nano-fluff structure, and the side with the nano-fluff structure is in contact with the composite sponge layer 3, and the composite sponge layer 3 is a porous elastic structure wrapped with conductive materials; the upper packaging layer 1, The lower packaging layer 6 is used to seal and fix the entire device; the first conductive electrode 4 and the second conductive electrode 2 each have a lead wire, which is bonded to one side of the electrode surface with silver paste for applying operating voltage and output measurement .

[0040] The second conductive electrode 2 is prepared by powder metallurgy, a...

Embodiment 2

[0051] This embodiment provides a method for preparing a wide-range flexible resistive pressure sensor, which includes the following steps:

[0052] ① Take a polyurethane sponge sheet with a thickness of 3-8mm and a polyimide film with a thickness of 100-300um, and then ultrasonically clean and dry it with ultrapure water, absolute ethanol, etc.; the polyimide film is used as a flexible base layer;

[0053] ② Cut the cleaned polyurethane sponge sheet into a square structure with a side length of 0.5-2 cm, and cut the cleaned polyimide film into a square structure with a side length of 1-3 cm as the sponge material of the composite sponge layer;

[0054] ③ The molybdenum electrode that has been powder metallurgy and mechanically polished is cut into a block sample with a side length of 5-15mm and a height of 1-5mm by wire cutting, using a low-load energy high-flux helium plasma with a bias voltage of 0-100V Radiation etching to obtain a molybdenum electrode with a nano-fluff st...

Embodiment 3

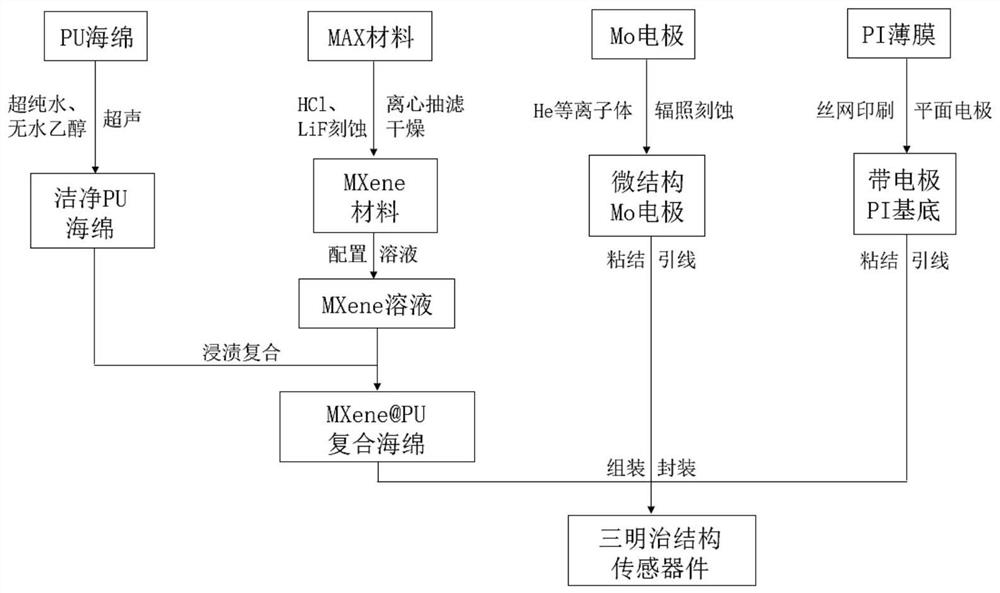

[0061] like figure 2 As shown, this embodiment provides a preparation method of a wide range flexible resistive pressure sensor:

[0062] 1. Ti 3 C 2 T x MXene material synthesis

[0063] ① Mix 40ml of HCl solution with a concentration of 9mol / L, 1.2g of Ti 3 AlC 2 The powder and 2gLiF were added into a plastic jar, sealed and stirred at a constant temperature of 35°C for 24h.

[0064] ②Pipe the solution after stirring in ① into a centrifuge tube, add ultrapure water and centrifuge at a speed of 5000r / min for 5min, pour off the supernatant in each centrifuge tube and add ultrapure water again, centrifuge 5 times in total .

[0065] ③Collect the centrifuged MXene aqueous solution in ②, use small-pore filter paper for suction filtration, and then vacuum-dry at 35°C for 24h to obtain Ti 3 C 2 T x Powder ready for use.

[0066] 2. Sensor device preparation

[0067] ① Take a polyurethane sponge sheet with a thickness of 5mm and a polyimide film with a thickness of 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com