Magnetic attapulgite cellulose composite microsphere as well as preparation method and application thereof

A technology of attapulgite and composite microspheres, applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problems of unfavorable adsorption of heavy metal cadmium, etc. The effect of grafting ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

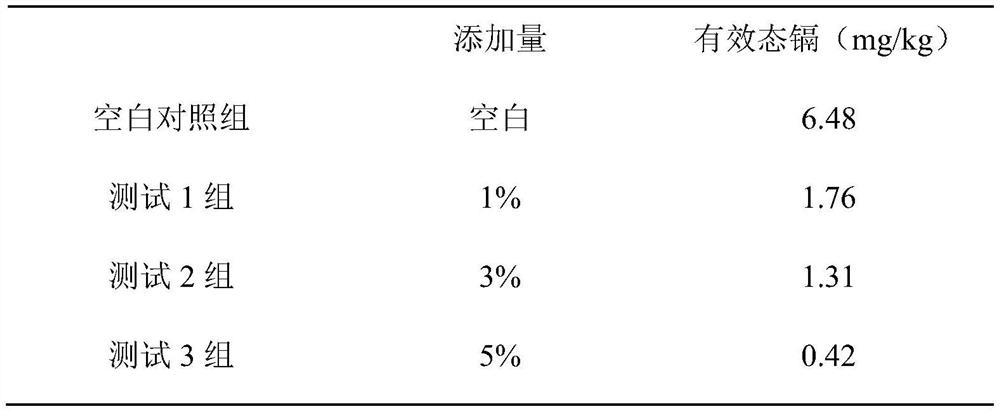

Embodiment 1

[0040] This embodiment provides a method for preparing magnetic attapulgite cellulose composite microspheres, comprising the following steps:

[0041] 1) Attapulgite (the specific surface area of attapulgite is 800m 2 / g) washing with water to remove impurities, passing through a 400-mesh sieve after drying, then weighing 30g of the sieved attapulgite, adding it to 300g of hydrochloric acid with a concentration of 4mol / L, stirring and activating at 90°C for 4h, and suction filtration. The product was washed with water until neutral, and then dried at 60°C for 12 hours to obtain activated attapulgite;

[0042] 2) Take 40 g of ionic liquid 1-allyl-3 methylimidazolium chloride salt, add 1 g of microcrystalline cellulose to the ionic liquid, and heat at 100° C. for 2 hours to completely dissolve the cellulose to obtain a cellulose solution;

[0043] 3) Add 0.5 g of activated attapulgite, 0.2 g of nano-ferric oxide and 0.15 g of calcium carbonate to the cellulose solution obtain...

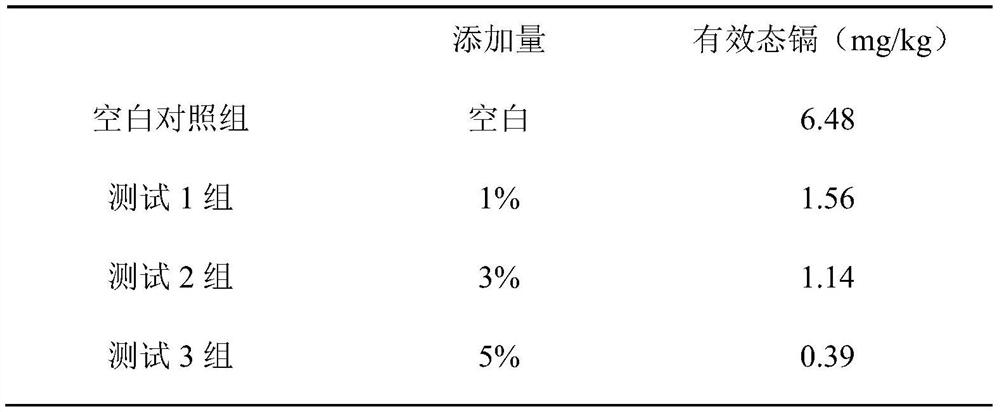

Embodiment 2

[0055] This embodiment provides a method for preparing magnetic attapulgite cellulose composite microspheres, comprising the following steps:

[0056] 1) Attapulgite (the specific surface area of attapulgite is 800m 2 / g) washing with water to remove impurities, passing through a 400-mesh sieve after drying, then weighing 30g of the sieved attapulgite, adding it to 300g of hydrochloric acid with a concentration of 4mol / L, stirring and activating at 90°C for 4h, and suction filtration. The product was washed with water until neutral, and then dried at 60°C for 12 hours to obtain activated attapulgite;

[0057] 2) Take 40 g of ionic liquid 1-allyl-3 methylimidazolium chloride salt, add 1 g of microcrystalline cellulose to the ionic liquid, and heat at 100° C. for 2 hours to completely dissolve the cellulose to obtain a cellulose solution;

[0058] 3) Add 1g of activated attapulgite to the cellulose solution obtained in step 2), 0.5g of nano-ferric oxide and 0.2g of calcium ca...

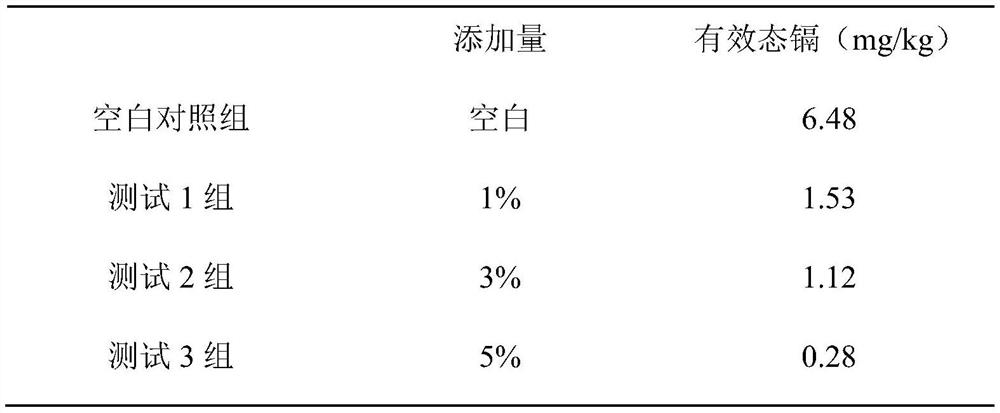

Embodiment 3

[0069] This embodiment provides a method for preparing magnetic attapulgite cellulose composite microspheres, comprising the following steps:

[0070] 1) Attapulgite (the specific surface area of attapulgite is 800m 2 / g) washing with water to remove impurities, passing through a 400-mesh sieve after drying, then weighing 30g of the sieved attapulgite, adding it to 300g of hydrochloric acid with a concentration of 4mol / L, stirring and activating at 90°C for 4h, and suction filtration. The product was washed with water until neutral, and then dried at 60°C for 12 hours to obtain activated attapulgite;

[0071] 2) Take 40 g of ionic liquid 1-allyl-3 methylimidazolium chloride salt, add 1 g of microcrystalline cellulose to the ionic liquid, and heat at 100° C. for 2 hours to completely dissolve the cellulose to obtain a cellulose solution;

[0072] 3) Add 1g of activated attapulgite to the cellulose solution obtained in step 2), 0.5g of nano-ferric oxide and 0.6g of calcium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com