In-situ remediation passivator for cadmium-copper contaminated rice field soil and preparation and use methods thereof

An in-situ remediation and contaminated soil technology, applied in the field of contaminated soil remediation, can solve problems such as the limited ability of chemical passivators to adjust soil fertility, differences in types and physical and chemical properties of heavy metal-contaminated soil, and different passivation remediation effects. Convenience, low price, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides an in-situ remediation passivator for cadmium-copper-contaminated paddy field soil, and the passivator is prepared through the following steps:

[0033] S1: Grinding calcium carbonate, humus and calcium magnesium phosphate fertilizer respectively;

[0034] S2: passing the calcium carbonate, humus and calcium magnesium phosphate fertilizer powder obtained in step S1 through a 150-mesh sieve;

[0035] S3: The calcium carbonate, humus and calcium-magnesium phosphate fertilizer powder sieved in step S2 are mixed according to the following mass percentages, 20% of calcium carbonate, 60% of humus, and 20% of calcium-magnesium phosphate fertilizer.

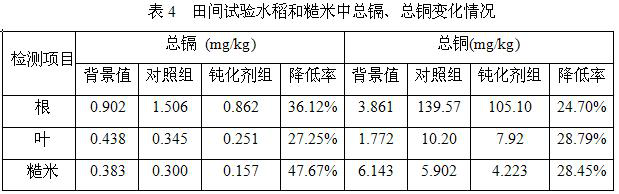

[0036] The cadmium copper polluted paddy field soil that embodiment 1 adopts, crosses 10 mesh soil sieves for subsequent use after air-drying, pulverizing, and its basic physicochemical property is as shown in table 1:

[0037]

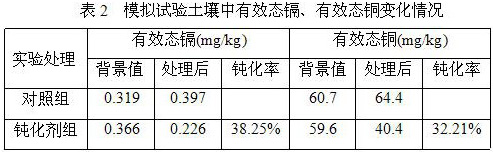

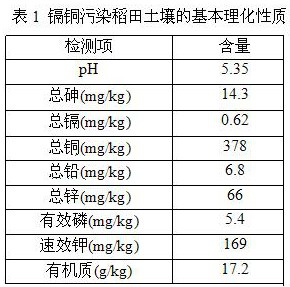

[0038] In order to verify the remediation effect of the passivating agent p...

Embodiment 2

[0048] The invention provides an in-situ remediation passivator for cadmium-copper-contaminated paddy field soil, and the passivator is prepared through the following steps:

[0049] S1: Grinding calcium carbonate, humus and calcium magnesium phosphate fertilizer respectively;

[0050] S2: Pass the calcium carbonate, humus and calcium magnesium phosphate fertilizer powder obtained in step S1 through a 120-mesh sieve;

[0051] S3: The calcium carbonate, humus and calcium-magnesium phosphate fertilizer powder sieved in step S2 are mixed according to the following mass percentages, 15% of calcium carbonate, 65% of humus, and 20% of calcium-magnesium phosphate fertilizer.

[0052] Adopt the passivator that embodiment 2 prepares to carry out the method for in-situ remediation of cadmium polluted paddy field soil, comprise the following steps:

[0053] S1: Before applying the passivating agent, the heavy metal content in the polluted rice field soil was detected first. After testin...

Embodiment 3

[0057] The invention provides an in-situ remediation passivator for cadmium-copper-contaminated paddy field soil, and the passivator is prepared through the following steps:

[0058] S1: Grinding calcium carbonate, humus and calcium magnesium phosphate fertilizer respectively;

[0059] S2: passing the calcium carbonate, humus and calcium magnesium phosphate fertilizer powder obtained in step S1 through a 160-mesh sieve;

[0060] S3: The calcium carbonate, humus and calcium-magnesium phosphate fertilizer powder sieved in step S2 are mixed according to the following mass percentages, 20% of calcium carbonate, 55% of humus, and 25% of calcium-magnesium phosphate fertilizer.

[0061] Adopt the passivator that embodiment 3 prepares to carry out the method for in-situ remediation of cadmium polluted paddy field soil, comprise the following steps:

[0062] S1: Before applying the passivating agent, the heavy metal content in the polluted paddy soil was detected. After testing, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com