Polypropylene composite dielectric with high energy storage density interlayer and preparation method thereof

A high energy storage density, dielectric technology, applied in chemical instruments and methods, layered products, flat products, etc., can solve the problems of reduced breakdown field strength and unsatisfactory improvement of energy storage performance, and achieve high energy storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

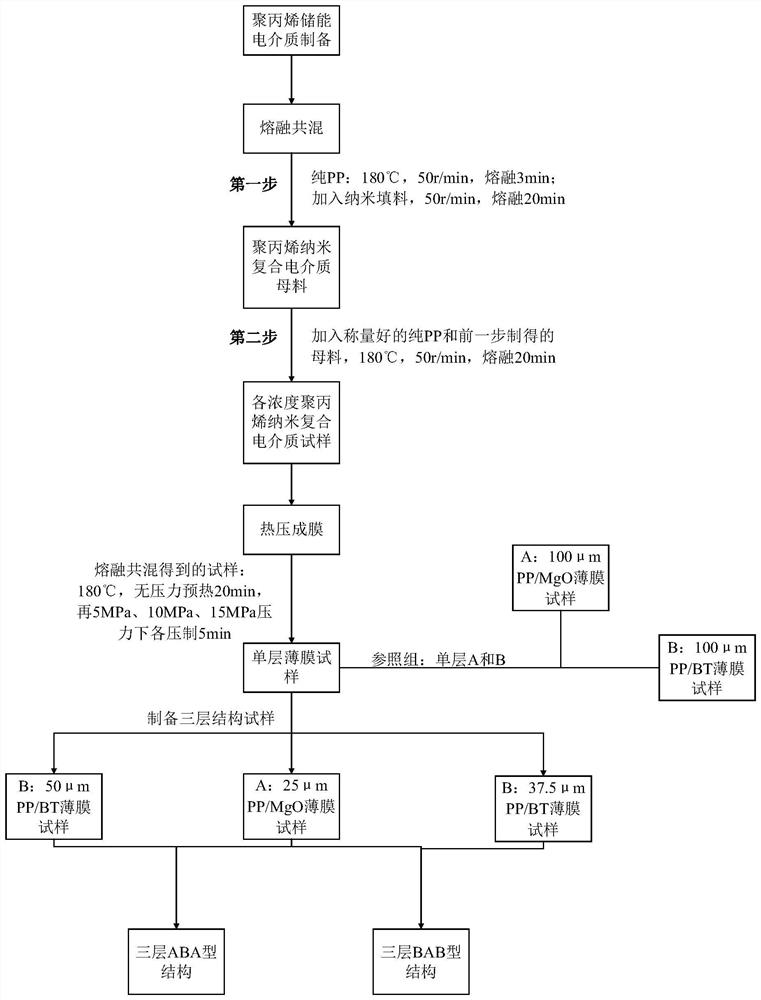

[0047] The preparation method of interlayer polypropylene composite dielectric with high energy storage density comprises the following steps:

[0048] Step 1, using two-step method to melt blend polypropylene (PP) base material and nanometer BaTiO 3 Granules, 10wt%, 20wt%, 30wt%, 40wt%, 45wt%, 50wt%, 55wt% and 60wt% PP / BaTiO 3 Nanocomposite dielectric samples were then hot-pressed PP / BaTiO with a flat vulcanizer using a step-by-step pressure boost method 3 Nanocomposite dielectrics, the vulcanization process of the flat vulcanizer is: first preheat for 20 minutes without pressure, then press for 5 minutes under 5MPa pressure, then press for 5 minutes under 10MPa pressure, and finally press for 5 minutes under 15MPa. After the end, keep the pressure and water cool to Take out the mold at about 35°C to get PP / BaTiO with a certain thickness 3 Single layer composite dielectric thin film specimen.

[0049] Step 2, adopt two-step method melt-blending polypropylene (PP) base mate...

Embodiment 1

[0064] refer to figure 1 , the preparation method of ABA type sandwich structure polypropylene nanocomposite dielectric (wherein A layer is 25 μm thick, the PP / MgO nanocomposite dielectric of doping content 0.5wt%; B layer is 50 μm thick, the PP / BaTiO of doping content 10wt% 3 single-layer composite dielectric), the specific steps are as follows:

[0065] Step 1, 50μm thick PP / BaTiO 3 Preparation of Nanocomposite Dielectric Films

[0066] Step 1.1. Preheat the mixer at 180°C. After reaching the set temperature, set the rotation speed to 5r / min. Put in 16g of PP base material, then increase the rotation speed to 50r / min, melt for 3min, and then reduce the rotation speed to 5r / min, then slowly add 24g of BaTiO 3 Nanoparticles, after being completely poured in, increase the speed to 50r / min, and blend for 20min; take out the blended sample to obtain PP / BaTiO with a concentration of 60wt%. 3 Nanocomposite dielectric masterbatch.

[0067] Step 1.2. Preheat the mixer at 180°C, ...

Embodiment 2

[0076] The preparation method of ABA type sandwich structure polypropylene nanocomposite dielectric (wherein A layer is 25 μm thick, the PP / MgO nanocomposite dielectric of doping content 0.5wt%; B layer is 50 μm thick, the PP / BaTiO of doping content 20wt% 3 single-layer composite dielectric), the specific steps are as follows:

[0077] Step 1, 50μm thick PP / BaTiO 3 Preparation of Nanocomposite Dielectric Films

[0078] Step 1.1, using melt blending to prepare PP / BaTiO with a concentration of 60wt% 3 Nanocomposite dielectric masterbatch, the specific implementation steps are the same as in Example 1.

[0079] Step 1.2. Preheat the mixer at 180°C. After it reaches the set temperature, adjust the speed to 5r / min. Put 20g of pure PP and 10g of 60wt% PP / BaTiO obtained in the previous step 3 For the nanocomposite dielectric masterbatch, increase the rotation speed to 50r / min, and blend for 20min. Take out the sample to obtain the concentration of 20wt% PP / BaTiO 3 Nanocomposite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com