Method for regulating crystal morphology and granularity of alpha-semi-hydrated gypsum in solution system

A hemihydrate gypsum and system technology, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium compounds, etc., can solve the problems of few, unable to generate carboxylate ions, and unable to effectively control the morphology of phase change products, etc. , to achieve the effects of short time, control of crystal particle size and reduction of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

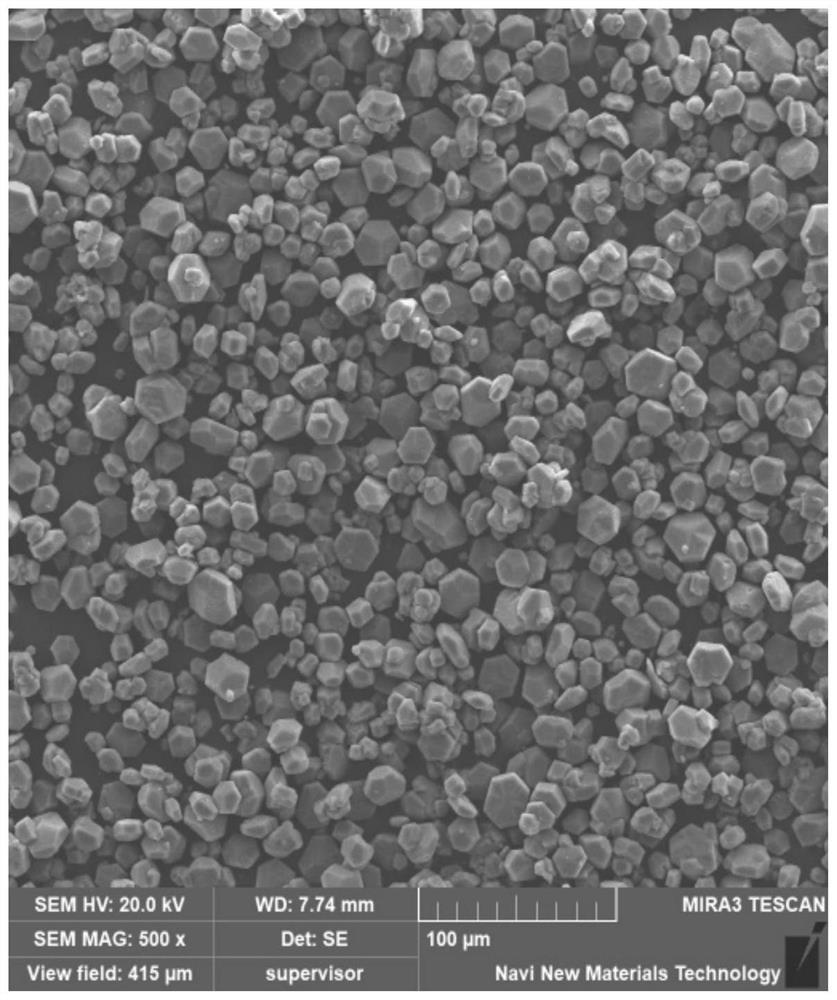

[0053] Prepare a sodium chloride solution with a mass fraction of 25%, add desulfurized gypsum (the mass fraction of dihydrate gypsum is 92%) to it according to the solid-to-liquid ratio of 1:4 and mix to form a gypsum suspension, and then add the gypsum suspension to the phase In the variable reactor, add 15×10 -4 mol / kg sodium succinate, react at 95°C for 2h, then filter while hot, wash the separated solid phase with boiling water and transfer to an oven at 60°C to dry to constant weight to obtain α-hemihydrate gypsum seed crystals Such as figure 1 As shown, the average length is about 7.56 μm, the average diameter is about 15.94 μm, and the average aspect ratio is about 0.48.

[0054] Prepare the hydrochloric acid solution of 0.4mol / L, add sodium chloride thereinto, form the mixed solution that the mass fraction of sodium chloride is 15%, the concentration of hydrochloric acid is 0.4mol / L, the mixed solution is joined in the phase change reactor, reaction temperature Set ...

Embodiment 2

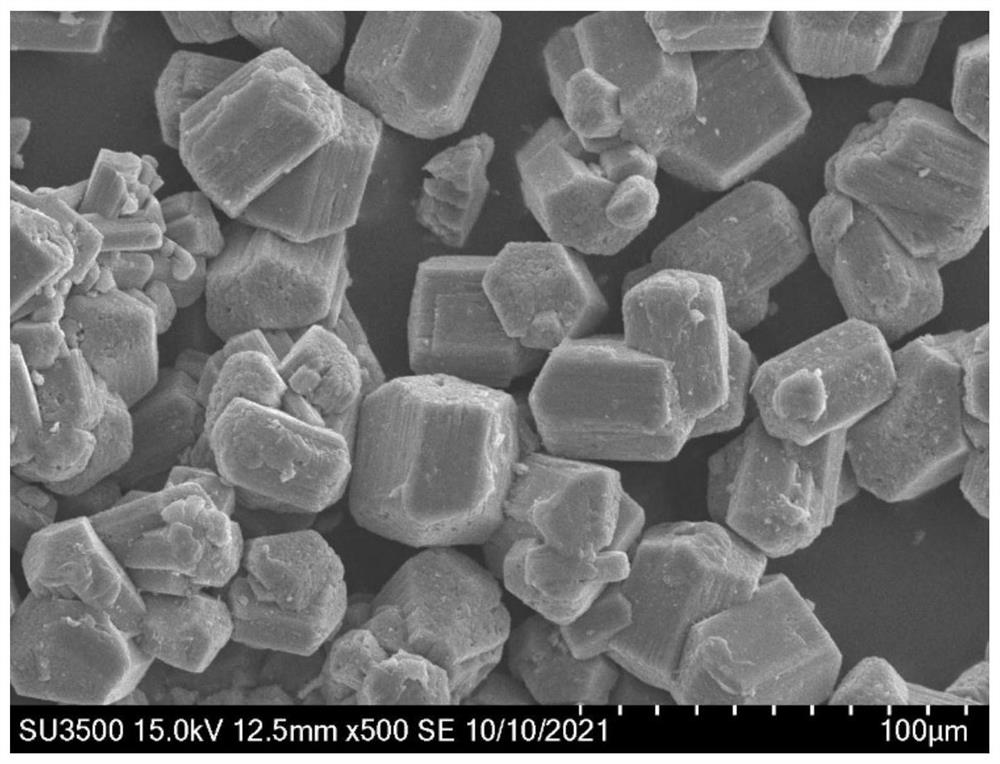

[0058] Prepare an aqueous solution of glycerol with a mass fraction of 45%, add desulfurized gypsum (dihydrate gypsum mass fraction of 92%) to it according to the solid-to-liquid ratio of 1:3 and mix to form a gypsum suspension, and then add the gypsum suspension to the phase change reaction In the device, add 15×10 at the same time -4 mol / kg sodium succinate, react at 95°C for 2h, then filter while hot, wash the separated solid phase with boiling water and transfer to an oven at 60°C to dry to constant weight to obtain α-hemihydrate gypsum seed crystals Such as Figure 4 As shown, the average length is about 16.34 μm, the average diameter is about 16.63 μm, and the average aspect ratio is about 1.02.

[0059] Prepare the hydrochloric acid solution of 0.6mol / L, add sodium chloride thereinto, form the mixed solution that the mass fraction of sodium chloride is 20%, the concentration of hydrochloric acid is 0.6mol / L, the mixed solution is joined in the phase change reactor, rea...

Embodiment 3

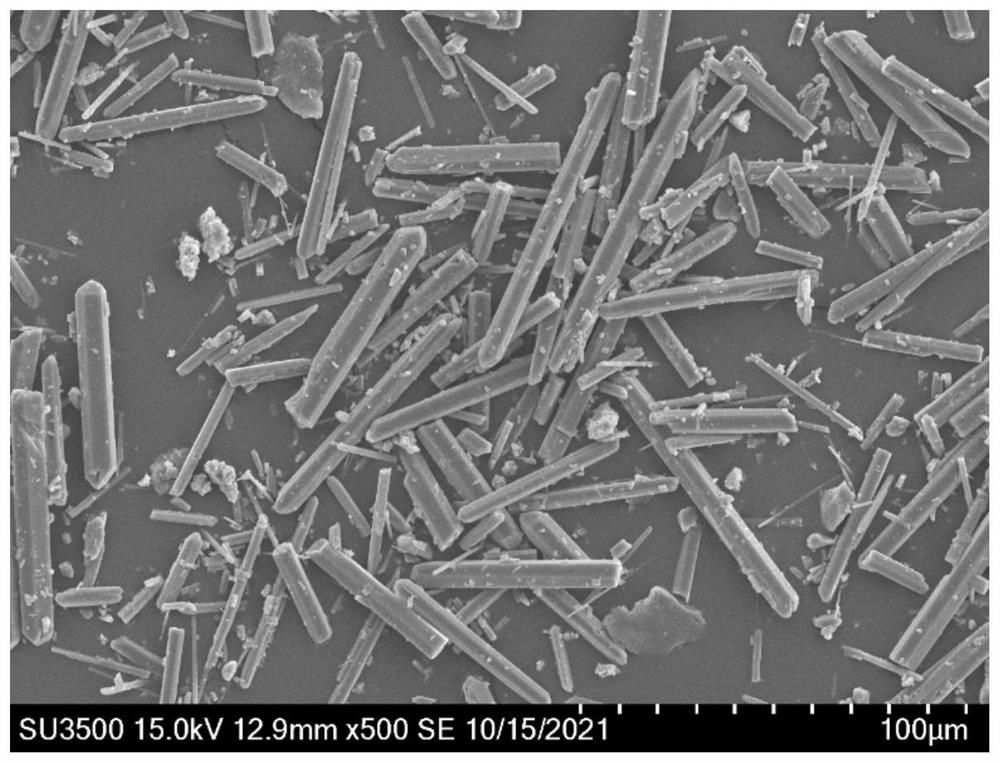

[0066] Prepare a potassium chloride solution with a mass fraction of 15%, add dihydrate gypsum (analytical pure) to it according to the solid-to-liquid ratio of 1:4 and mix to form a gypsum suspension, then add the gypsum suspension to the phase change reactor, Simultaneously join 1.5×10 -4 mol / kg sodium citrate, reacted at 95°C for 2h, then filtered while hot, and the separated solid phase was washed with boiling water and transferred to an oven at 60°C to dry to constant weight to obtain α-hemihydrate gypsum seed crystals such as Figure 10 As shown, the average length is about 29.08 μm, the average diameter is about 16.31 μm, and the average aspect ratio is about 1.76.

[0067] Prepare a 1.2mol / L sulfuric acid solution, add sodium sulfate thereto to form a mixed solution with a mass fraction of sodium sulfate of 10% and a sulfuric acid concentration of 1.2mol / L, add the mixed solution to the phase change reactor, and set the reaction temperature When the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com