Preparation method of catalyst and preparation method of chlorine-containing unsaturated polyester

An unsaturated and catalyst technology, applied in the field of preparation of chlorine-containing unsaturated polyester, can solve problems such as no practical use value, and achieve the problem of solving solid waste in production lines, shortening reaction time, and improving flame retardancy and heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Catalyst preparation:

[0050] Add 21.8g of pyrophthalic anhydride, 16.66g of isophorone diamine and 346g of DMAC into a 2000ml three-necked flask, start stirring, stir and dissolve until the viscosity no longer increases, and obtain a polyamic acid solution; add 0.77g to the solution sebacic acid and 2.31g of N-phenyl-N'-phenylbisphthalimide with formula A structure, continue to stir until dissolved, add 0.04g of acetic anhydride, 0.04g of pyridine, and continue to stir for 3h to prepare polyimide solution. The polyimide solution was mixed with 1038g of water and pulverized with a wet pulverizer, and the obtained solid was filtered and washed with boiling water 4 times, each time with 308g of water. The solid obtained after washing was dried in absolute vacuum at 140° C. for 24 hours to prepare catalyst a.

[0051] Resin preparation:

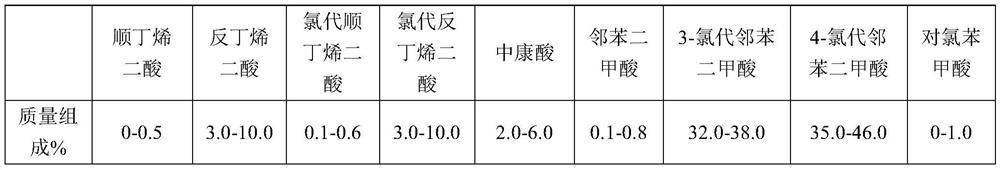

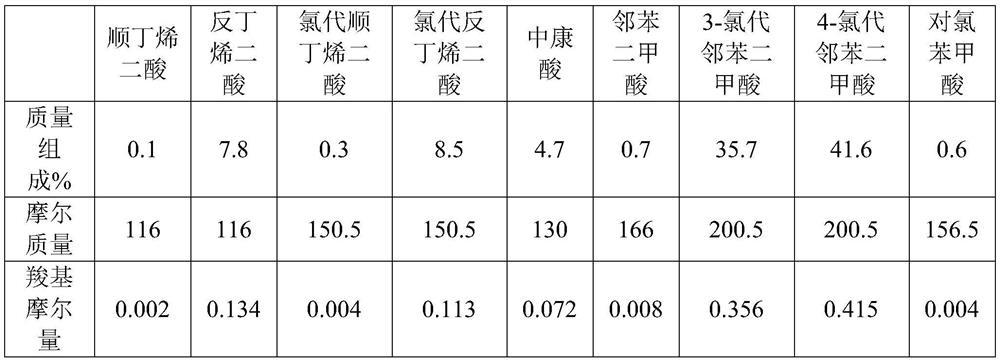

[0052] Connect a condenser, a water separator and an agitator to a 1000ml three-necked flask, add 100g of chlorinated o-xylene gas-p...

Embodiment 2

[0056] Catalyst preparation:

[0057] Add 29.4g of biphenyl dianhydride, 16.83g of isophorone diamine, and 262g of DMF into a 2000ml three-necked flask, start stirring, stir and dissolve until the viscosity no longer increases, and obtain a polyamic acid solution; add 1.85g to the solution Dodecanedioic acid and 9.25g of N-phenyl-N'-phenylbisphthalimide of the formula B structure, continue to stir until dissolved, add 0.09g of acetic anhydride, 0.09g of pyridine, continue to stir for 3h, Prepare polyimide solution. The polyimide solution was mixed with 1048g of water and pulverized with a wet pulverizer, and the obtained solid was filtered and washed with boiling water 4 times, each time with 462g of water. The solid obtained after washing was dried in absolute vacuum at 145° C. for 24 hours to prepare catalyst b.

[0058] Resin preparation:

[0059] Connect a condenser, a water separator and an agitator to a 1000ml three-necked flask, add 100g of chlorinated o-xylene gas-p...

Embodiment 3

[0063] Catalyst preparation:

[0064] Add 32.2g of benzophenone dianhydride, 11.286g of 1,4-cyclohexanediamine and 174g of NMP into a 2000ml three-necked flask, start stirring, stir and dissolve until the viscosity no longer increases, and obtain a polyamic acid solution; add 2.61g of dodecanedioic acid and 20.87g of N-phenyl-N'-phenylbisphthalimide with formula A structure, continue to stir until dissolved, add 0.13g of acetic anhydride, 0.13g of pyridine, and continue to stir 3h, made of polyimide solution. The polyimide solution was mixed with 1739g of water and pulverized with a wet pulverizer, and the obtained solid was filtered and washed four times with 522g of water each time. The solid obtained after washing was dried in absolute vacuum at 150° C. for 24 hours to obtain catalyst c.

[0065] Resin preparation:

[0066] Connect the condenser tube, water separator and stirrer on the 1000ml three-necked flask, add 100g of chlorinated o-xylene gas-phase oxidation by-pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com