Magnesium alloy rotary body structural part and preparation process thereof

A preparation process and technology of gyratory bodies, applied in the field of magnesium alloys, can solve problems such as poor structure uniformity of forgings, uneven metal flow, and low local mechanical properties, and achieve the effects of ensuring uniform plastic flow, improving mechanical properties, and reducing the risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mg-10.2Li-3.1Al-2.8Zn (wt.%) magnesium-lithium alloy vacuum smelted casting ingot is turned into a forged billet with a diameter of 290mm and a length of 500mm;

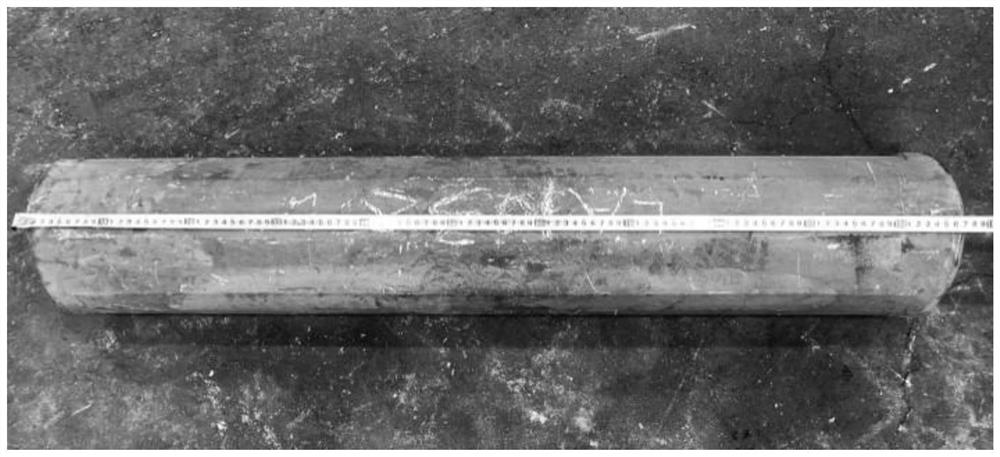

[0031] The forging billet is heated to 270°C with the furnace, and after 6 hours of heat preservation, the billet is opened for multi-directional large deformation forging. Upsetting 10%, after flattening the two ends, then pulling out, during the process, the forging billet is reversed once, after forging, it is air-cooled to room temperature, and the diameter of the forging is 195mm, and the length is 1060mm, such as figure 1 shown;

[0032] The forgings are sawed according to the length of 200mm to obtain multiple ingots. The ingots are heated with the furnace to 220°C for 5 hours, the mold is preheated to 220°C, and the die forging is formed once. The speed of die forging is 4mm / s, and the reduction is 95%. The die forgings are then demolded immediately and air cooled to room temperature;

[0033] The di...

Embodiment 2

[0035] Mg-9.8Li-3.3Al-2.6Zn (wt.%) magnesium-lithium alloy vacuum smelted casting ingots were turned and blanked to obtain a forged billet with a diameter of 260 mm and a length of 480 mm;

[0036]The forging billet is heated to 270°C with the furnace, and after holding for 6 hours, multi-directional large deformation forging is carried out. Upsetting 13%, after flattening the two ends, then pulling out, the forging billet is reversed once during the process, after forging, it is air-cooled to room temperature, and the diameter of the forging is 190mm, and the length is 870mm;

[0037] The forging is sawed according to the length of 195mm to obtain multiple ingots. The ingots are heated with the furnace to 240°C for 5 hours, the mold is preheated to 200°C, and the die forging is formed once. The die forging reduction speed is 6mm / s and the reduction is 94.9%. The die forgings are then demolded immediately and air cooled to room temperature;

[0038] The die forgings were subj...

Embodiment 3

[0040] Mg-11.3Li-2.8Al-3.5Zn (wt.%) magnesium-lithium alloy vacuum smelted casting ingots were turned and blanked to obtain a forged billet with a diameter of 255 mm and a length of 520 mm;

[0041] The forging billet is heated to 300°C with the furnace, and after 6 hours of heat preservation, multi-directional large deformation forging is carried out to open the billet. Upsetting 16%, after flattening the two ends, then elongating, the forging billet is reversed once during the process, after forging, it is air-cooled to room temperature, and the diameter of the forging is 180mm, and the length is 1010mm;

[0042] The forging is sawed according to the length of 240mm to obtain multiple ingots. The ingots are heated with the furnace to 290°C for 5 hours, the mold is preheated to 220°C, and the die forging is formed once. The die forging reduction speed is 9mm / s and the reduction amount is 95.8%. The die forgings are then demolded immediately and air cooled to room temperature;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com