Preparation method of magnesium-aluminum-vanadium co-doped lithium cobalt oxide positive electrode material

A positive electrode material and co-doping technology, applied in positive electrodes, chemical instruments and methods, cobalt compounds, etc., can solve the problems of inability to improve the charging capacity of lithium cobaltate materials, short service life, slow charging speed, etc., and achieve reduction Polarization effect, good cycle performance, and the effect of increasing the discharge platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 200g of KL-III lithium cobaltate, 95.25g of battery grade lithium carbonate, 0.4g of magnesium oxide, 0.93g of aluminum oxide, and 0.97g of ammonium vanadate, and mix them in a planetary ball mill for 60 minutes.

[0034] (2) Transfer the mixed powder to a sagger, transfer the sagger to a muffle furnace, heat up from room temperature to 1060°C for 10 hours at a heating rate of 5°C / min, and continuously feed air as an oxygen source during the sintering process; After cooling down to room temperature naturally, take it out.

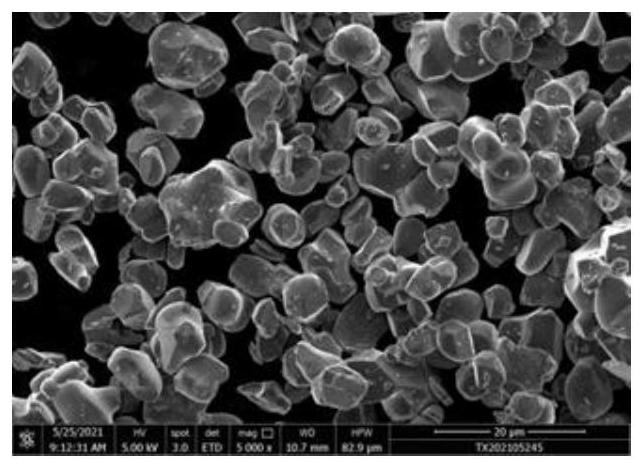

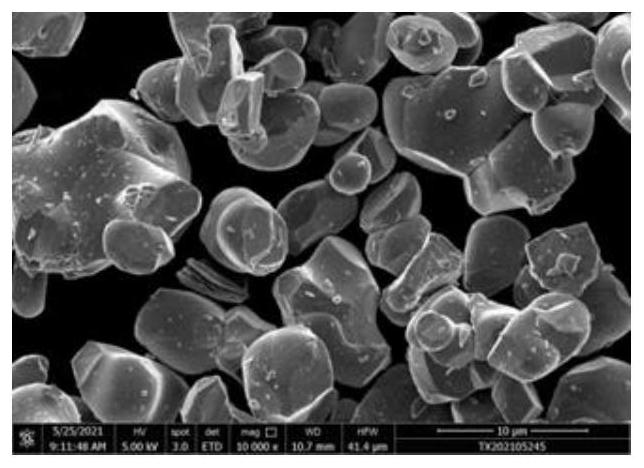

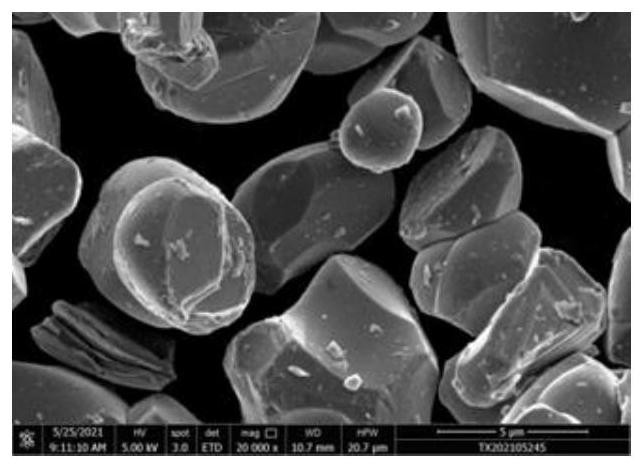

[0035] (3) Place the obtained sample in a small universal pulverizer, pulverize it for 20 seconds, pour the pulverized sample into a 325-mesh sieve for sieving, collect the sieved sample, and obtain a co-doped positive electrode material powder, D50 = 16.5 μm.

[0036] (4) The prepared LiCoO 2 Mix the sample, conductive agent SP, and binder PVDF at a mass ratio of 90:5:5, add the binder NMP, stir evenly, and coat it on a 12 μm thick alumi...

Embodiment 2

[0038] (1) Put KL-III type cobalt oxide, lithium carbonate, nano-magnesia, nano-alumina, and ammonium vanadate raw materials into a high-speed mixing device and mix for 10 minutes, wherein the molar ratio of lithium element to cobalt element is 1.04, and the nano-magnesium oxide The mass fraction is 0.05%, the mass fraction of nano-alumina is 0.05%, and the mass fraction of ammonium vanadate is 0.05%;

[0039] b. Place the mixed raw materials in step a in a box furnace at 500°C, and sinter at a constant temperature in an air atmosphere for 2 hours. After the sintering is completed, naturally cool to room temperature and take it out;

[0040] c. After the product obtained in step b is pulverized through a 200-mesh sieve, a magnesium-aluminum-vanadium co-doped lithium cobalt oxide positive electrode material is obtained. The obtained product has a D50 of 16.2 μm and a discharge capacity of 188.7 Mah / g at a rate of 0.2C and a voltage of 4.5V.

Embodiment 3

[0042] (1) Put cobalt oxide, lithium carbonate, nano-magnesia, nano-alumina, and ammonium vanadate raw materials into a three-dimensional mixing device and mix for 100 minutes, wherein the molar ratio of lithium element to cobalt element is 1.05, and the mass fraction of nano-magnesia is 0.1 %, the massfraction of nano-alumina is 0.3%, and the massfraction of ammonium vanadate is 0.3%;

[0043] b. Place the mixed raw materials in step a in a box furnace at 800°C, and sinter at a constant temperature in an air atmosphere for 10 hours. After the sintering is completed, naturally cool to room temperature and take it out;

[0044]c. After the product obtained in step b is pulverized through a 350-mesh sieve, a magnesium-aluminum-vanadium co-doped lithium cobalt oxide positive electrode material is obtained. The obtained product has a D50 of 16.4 μm and a discharge capacity of 188.2 Mah / g at a rate of 0.2C and a voltage of 4.5V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com