Hierarchical pore carbon-based photo-thermal phase change material as well as preparation method and application thereof

A phase change material and multi-level hole technology, which is applied in the field of phase change materials to achieve the effects of high photothermal conversion efficiency, efficient and fast heat transfer and light absorption, and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

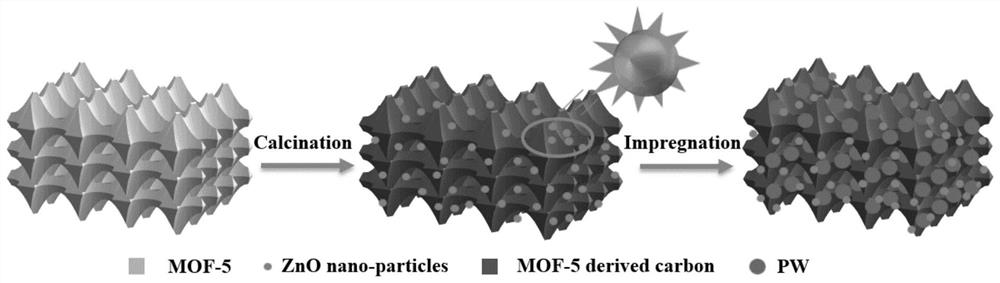

[0052] A method for preparing a hierarchically porous carbon-based photothermal phase change material, specifically comprising the following steps:

[0053] (1) Preparation of MOF-5:

[0054] Zn(NO 3 ) 2 .6H 2 A solution of O (12.39 g) and terephthalic acid (3.06 g) dissolved in 360 mL of dimethylformamide (DMF) was stirred in a flask for 1 h, then triethylamine (14.4 g) was slowly dropped dropwise. After stirring for 30 min, 2.7 ml of 30% hydrogen peroxide aqueous solution was added, and stirred for another 30 min. Finally, the obtained solid was filtered, washed three times with DMF and three times with methanol, and dried at 80° C. for 24 h.

[0055] (2) Preparation of MOF-5-PC carrier material:

[0056] MOF-5 was directly carbonized to obtain MOF-5-PC. Put the MOF-5 white powder in an alumina crucible, heat it to a certain temperature X at a rate of 5 °C / min under nitrogen flow, maintain the temperature X for 3 hours, and then cool it to room temperature at a rate of...

Embodiment 2

[0070] A method for preparing a three-dimensional metal-organic framework derivative-based photothermal composite phase change material, specifically comprising the following steps:

[0071] (1) Preparation of IRMOF-3:

[0072] Zn(NO 3 ) 2 .6H 2 O (595 mg) and 2-aminoterephthalic acid (181 mg) were dissolved in 50 ml of DMF, stirred vigorously for 5 min, then added triethylamine (101 mg), and stirred for 120 min. The generated precipitate was collected by centrifugation, washed three times in DMF and three times with methanol, and then dried in a vacuum oven at 80° C. for 24 hours to obtain a sample.

[0073] (2) Preparation of IRMOF-3-PC carrier material:

[0074] IRMOF-3 was directly carbonized to obtain IRMOF-3-PCs. Put IRMOF-3 white powder in an alumina crucible, heat it to a certain temperature X at a rate of 5°C / min under nitrogen flow, and maintain it for 3 hours, and then cool it to room temperature at a rate of 10°C / min to obtain a carbon material .

[0075] Amon...

Embodiment 3

[0080] A method for preparing a three-dimensional metal-organic framework derivative-based photothermal composite phase change material, specifically comprising the following steps:

[0081] (1) Preparation of ZIF-8:

[0082] Zn(NO 3 ) 2 .6H 2 O (623 mg) and 2-methylimidazole (221 mg) were dissolved in 25 mL of methanol solution, respectively. Then Zn(NO 3 ) 2 .6H 2 The O methanol solution was quickly poured into the 2-methylimidazole methanol solution, and stirred vigorously for 5 min. After the stirring, the samples were aged for 10min, 3h and 24h respectively. Finally, the white precipitate was centrifuged and washed several times with methanol and dried overnight at room temperature.

[0083] (2) Preparation of ZIF-8-PC carrier material:

[0084] ZIF-8 was directly carbonized to obtain ZIF-8-PCs. Put ZIF-8 white powder in an alumina crucible, heat it to a certain temperature X at a rate of 5°C / min under nitrogen flow, and maintain it for 3 hours, and then cool it...

PUM

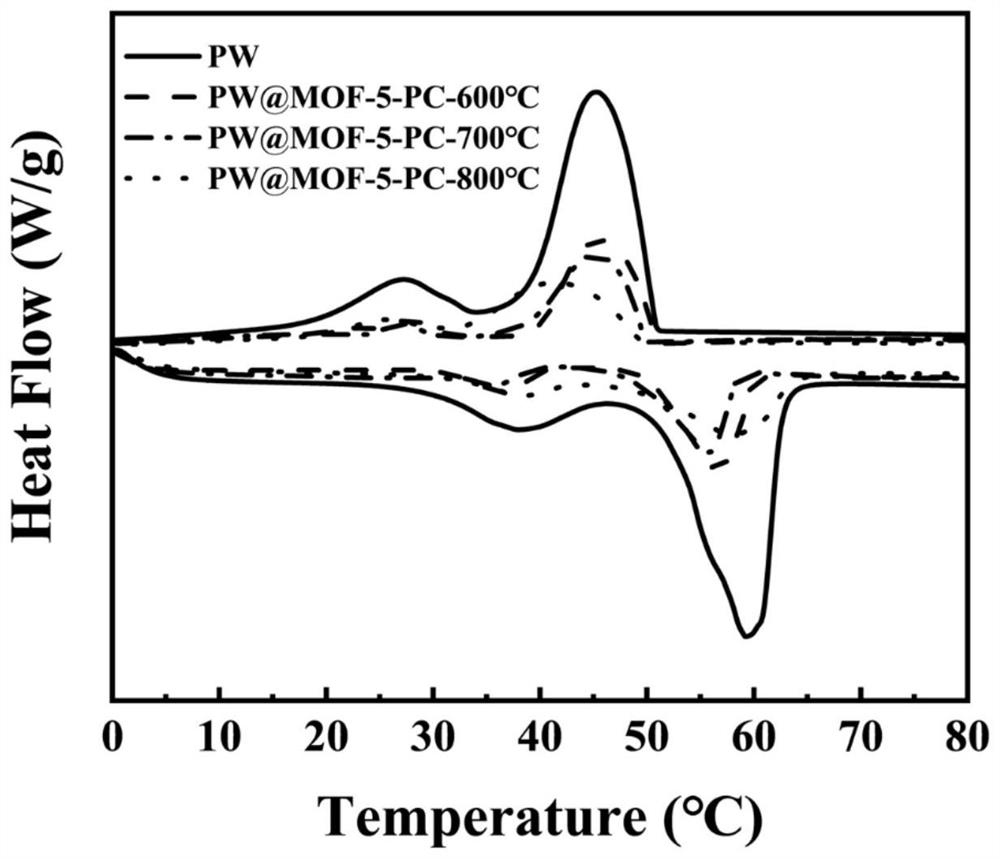

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com