Preparation method of low-fat soybean plant cream

A soybean plant and soybean oil body technology, applied in the production/processing of edible oil/fat, edible oil/fat composition, etc., can solve the problems of high oil content and heat, high hydrogenated oil content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

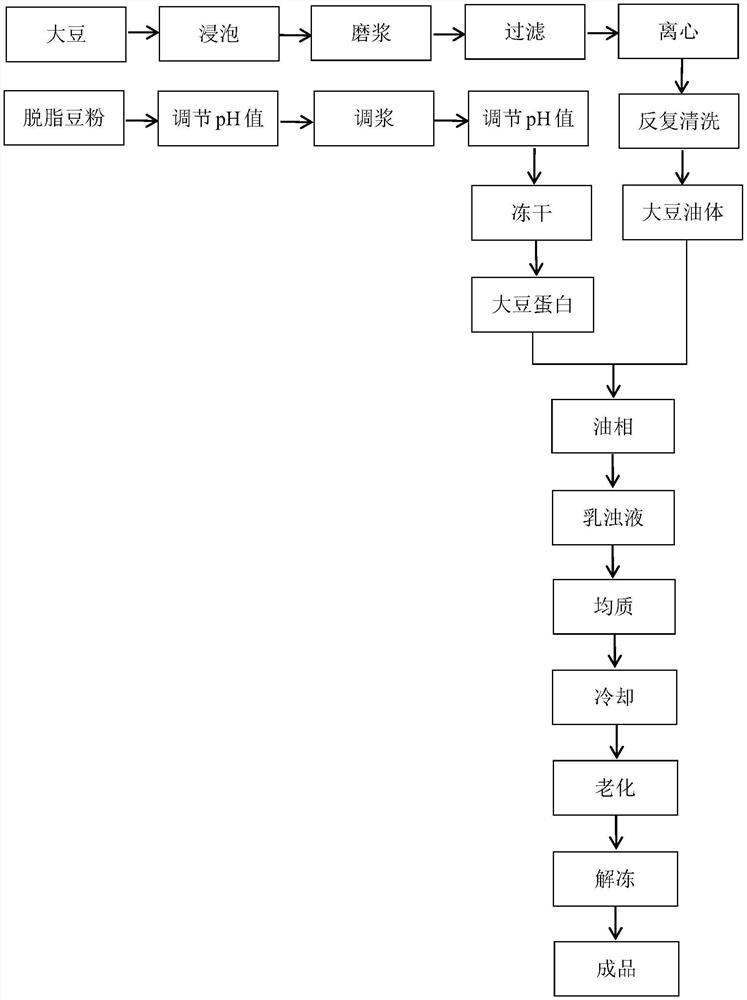

Image

Examples

preparation example Construction

[0016] A kind of preparation method of low-fat perilla oil flavor salad dressing is characterized in that, comprises the following steps:

[0017] (1) Soybean oil bodies are extracted from soybean milk. Soak soybeans and water in distilled water at a ratio of 1:5 (w / v) to liquid, and place them at 4°C for 18 hours. Soybean after soaking is placed in the buffer solution of pH 7.5 (comprising 50mmol / LTris-HCl, 0.4mol / L sucrose, 0.5mol / L sodium chloride, soybean and buffer solution solid-liquid ratio after soaking are 1:5, w / In v), stir for 180s with a crushing mixer to obtain a soybean homogenate. Remove bean dregs by filtering with three layers of filter cloth, centrifuge the filtrate at 4°C and 10,000×g for 30 min, and collect the upper layer of emulsion. The emulsion was washed 4 times with a buffer solution (50 mmol / L, Tris-HCl buffer solution 1:5, w / v) to obtain soybean oil bodies. (2) Emulsifier soy protein isolate was prepared by alkali-dissolving and acid-extracting. ...

Embodiment 1

[0018] Example 1: (1) Soybean oil bodies are extracted from soybean milk. Soak soybeans and water in distilled water at a solid-to-liquid ratio of 1:5 (w / v), and place them at 4°C for 18 hours. Soybean after soaking is placed in the buffer solution of pH 7.5 (comprising 50mmol / LTris-HCl, 0.4mol / L sucrose, 0.5mol / L sodium chloride, soybean and buffer solution solid-liquid ratio after soaking are 1:5, w / In v), stir for 180s with a crushing mixer to obtain a soybean homogenate. Remove bean dregs by filtering with three layers of filter cloth, centrifuge the filtrate at 4°C and 10,000×g for 30 min, and collect the upper layer of emulsion. The emulsion was washed 4 times with a buffer solution (50 mmol / L, Tris-HCl buffer solution 1:5, w / v) to obtain soybean oil bodies. (2) Emulsifier soy protein isolate was prepared by alkali-dissolving and acid-extracting. Edible defatted soybean powder was dispersed in deionized water (1:15, w / v), and the pH was adjusted to 9.0. The mixture wa...

Embodiment 2

[0019] Example 2: (1) Soybean oil bodies are extracted from soybean milk. Soak soybeans and water in distilled water at a solid-to-liquid ratio of 1:5 (w / v), and place them at 4°C for 18 hours. Soybean after soaking is placed in the buffer solution of pH 7.5 (comprising 50mmol / LTris-HCl, 0.4mol / L sucrose, 0.5mol / L sodium chloride, soybean and buffer solution solid-liquid ratio after soaking are 1:5, w / In v), stir for 180s with a crushing mixer to obtain a soybean homogenate. Remove bean dregs by filtering with three layers of filter cloth, centrifuge the filtrate at 4°C and 10,000×g for 30 min, and collect the upper layer of emulsion. The emulsion was washed 4 times with a buffer solution (50 mmol / L, Tris-HCl buffer solution 1:5, w / v) to obtain soybean oil bodies. (2) Emulsifier soy protein isolate was prepared by alkali-dissolving and acid-extracting. Edible defatted soybean powder was dispersed in deionized water (1:15, w / v), and the pH was adjusted to 9.0. The mixture wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com