Needle-shaped carbon nano tube for packaging magnetic particles and preparation method of needle-shaped carbon nano tube

A technology of magnetic particles and carbon nanotubes, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as complex operation, hidden safety hazards, cumbersome and complicated, etc. Excellent magnetic properties and the effect of increasing the acceptable absorption bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

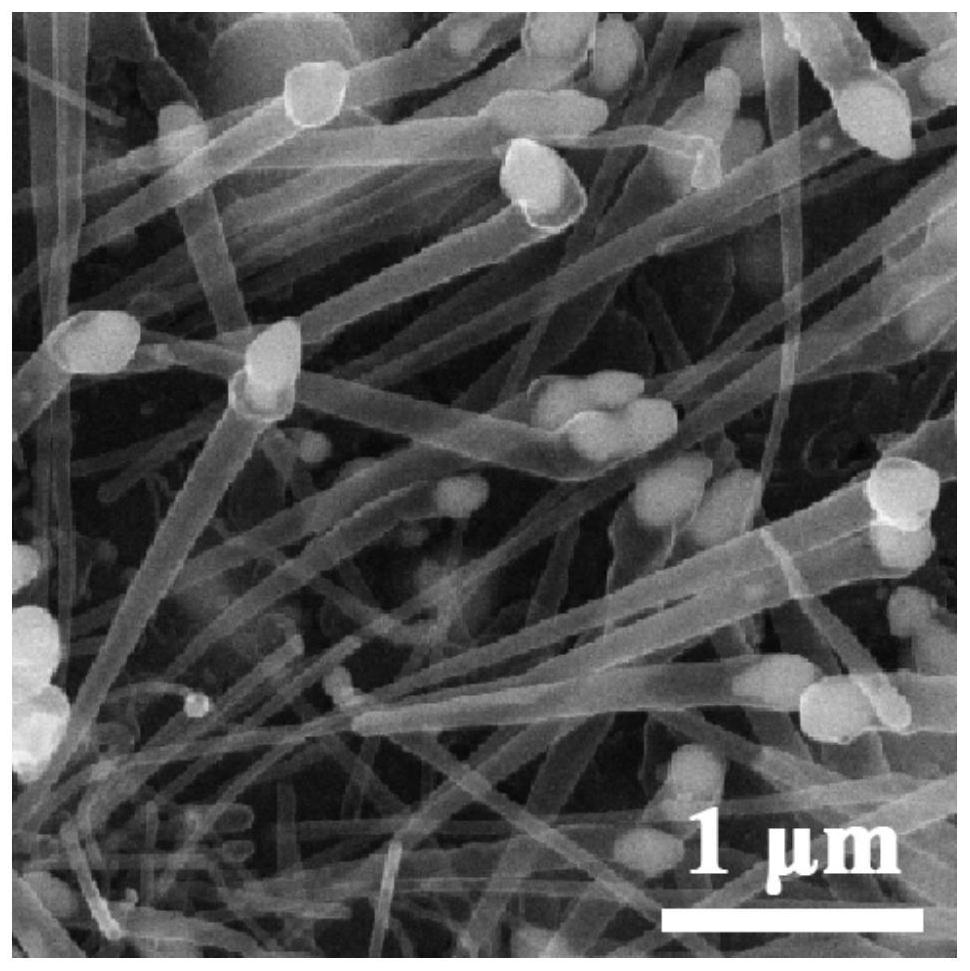

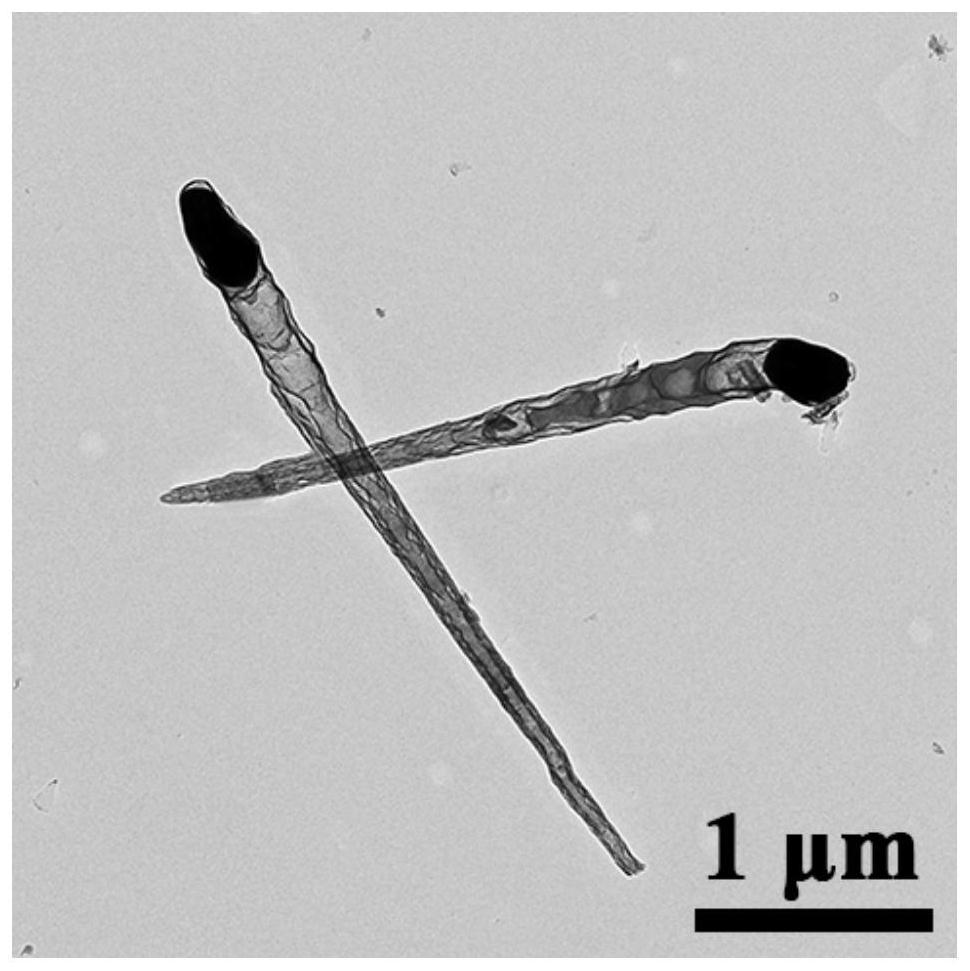

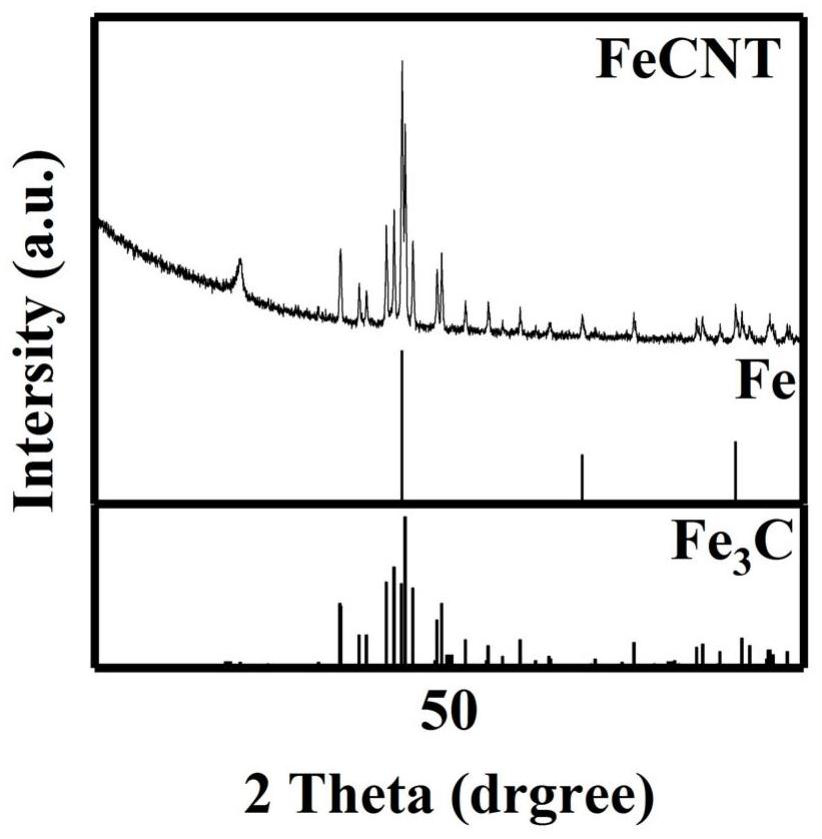

[0035] (1) Weigh 3.0g of ferric chloride hexahydrate and dissolve it in 30mL of ethanol solution, place it in an oil bath at 60°C, add 3.0g of melamine after the ferric chloride hexahydrate is completely dissolved, and stir the mixture thoroughly with magnetic force. Dry in an oven at 60°C for 24 hours to obtain an orange powder;

[0036] (2) Place the orange-yellow powder prepared in step (1) in a container, put it into the temperature-controlled area of the tube furnace, and under nitrogen atmosphere (gas flow rate 60mL / min), the heating rate is 5°C / min Heat at 700°C for 3 hours, and cool to room temperature to obtain black powder, which is needle-shaped carbon nanotubes.

Embodiment 2

[0038] The difference between this embodiment and Example 1 is that ferric chloride hexahydrate is used instead of iron acetylacetonate in step (1), and other steps and parameters are the same as in Example 1.

Embodiment 3

[0040] The difference between this embodiment and embodiment 1 is that the ethanol solution in step (1) is changed to deionized water, and other steps and parameters are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com