High-performance cord fabric rubber for tires and preparation method of high-performance cord fabric rubber

A high-performance, cord fabric technology, applied in the rubber field, can solve the problems of various physical properties deterioration, large sulfur, etc., and achieve the effect of reducing heat generation, small hysteresis loss, and reducing compression heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

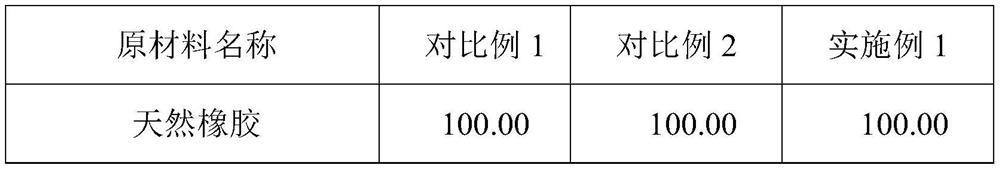

[0032] According to formula in table 1, the raw material of preparation embodiment 1 and comparative example 1, comparative example 2

[0033] Table 1 raw material formula

[0034]

[0035]

[0036] According to the formula in Table 1, the cord glue is prepared by the following method:

[0037](1) One stage of mastication: take the respective components by weight according to Table 1, start the internal mixer, set the rotor speed of the internal mixer to 45rpm, the mixing pressure to 10MPa, the cooling water temperature to 30°C, and the rotor temperature to 35°C, then add natural rubber, masticate for 35 seconds to lift up the top bolt, stay for 10 seconds to press on the top bolt, lift the top bolt at the mixing temperature to 145°C, reduce the speed to 30rpm, stay for 15 seconds to press on the top bolt, wait The temperature is up to 160°C to remove the glue, and a section of plain glue is obtained;

[0038] (2) Second-stage master mixing: Start the internal mixer, s...

Embodiment 2

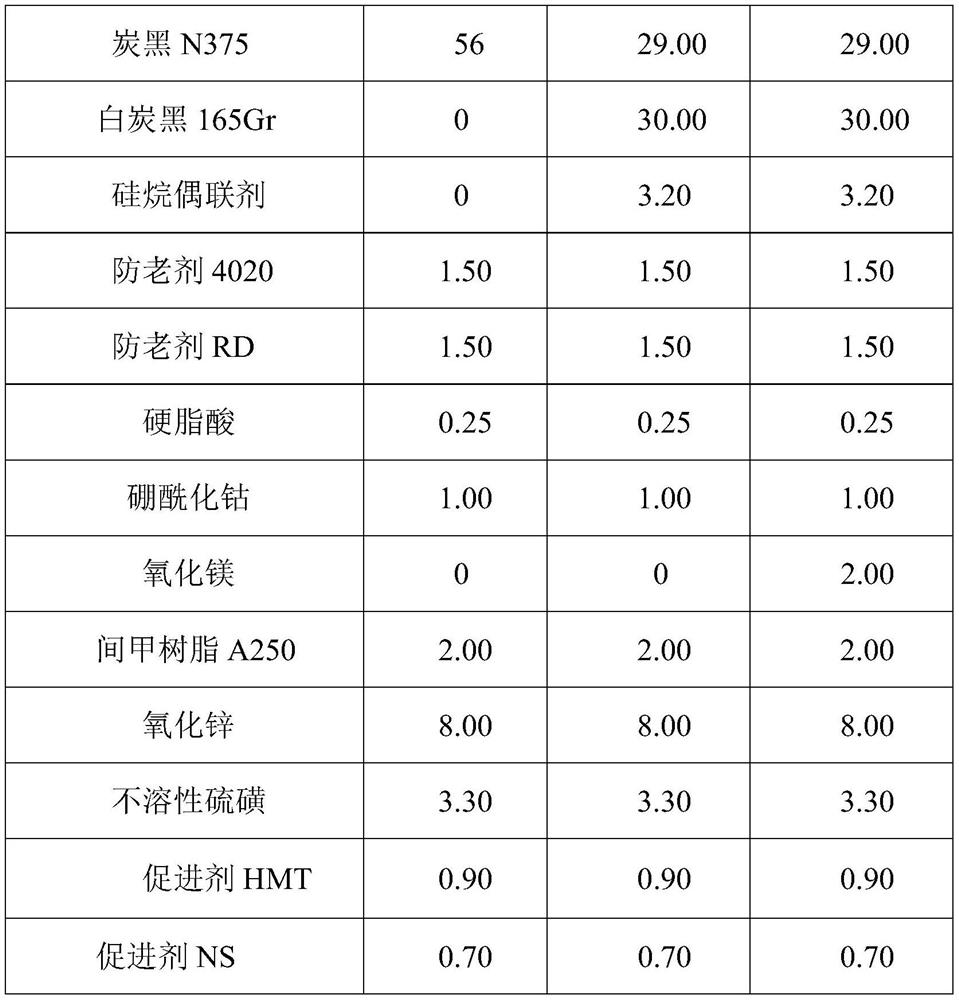

[0047] Embodiment 2 The formula of high-performance cord rubber for tires is as shown in Table 3:

[0048] Table 3 Example 2 Cord Glue Formula

[0049] raw material name parts by weight natural rubber 70.00 Isoprene Rubber 30.00 Carbon black N326 30.00 Carbon black N660 40.00 Silica 165Gr 8.00 A silane coupling agent 0 Antiaging agent 4020 1.00 Antiaging agent RD 1.00 stearic acid 3.00 Cobalt boroacylate 0 magnesium oxide 4.00 Meta-formic resin A250 0 Zinc oxide 10.00 insoluble sulfur 5.40 Accelerator HMT 0 Accelerator NS 1.50 Anti-scorch agent CTP 0.50 Anti-reversion agent 3.0

[0050] According to the formula in Table 3, the cord glue is prepared by the following method:

[0051] (1) One stage of mastication: Weigh each component of the corresponding weight portion, start the internal mixer, set the rotor speed of the internal mixer to be 40rpm, the mix...

Embodiment 3

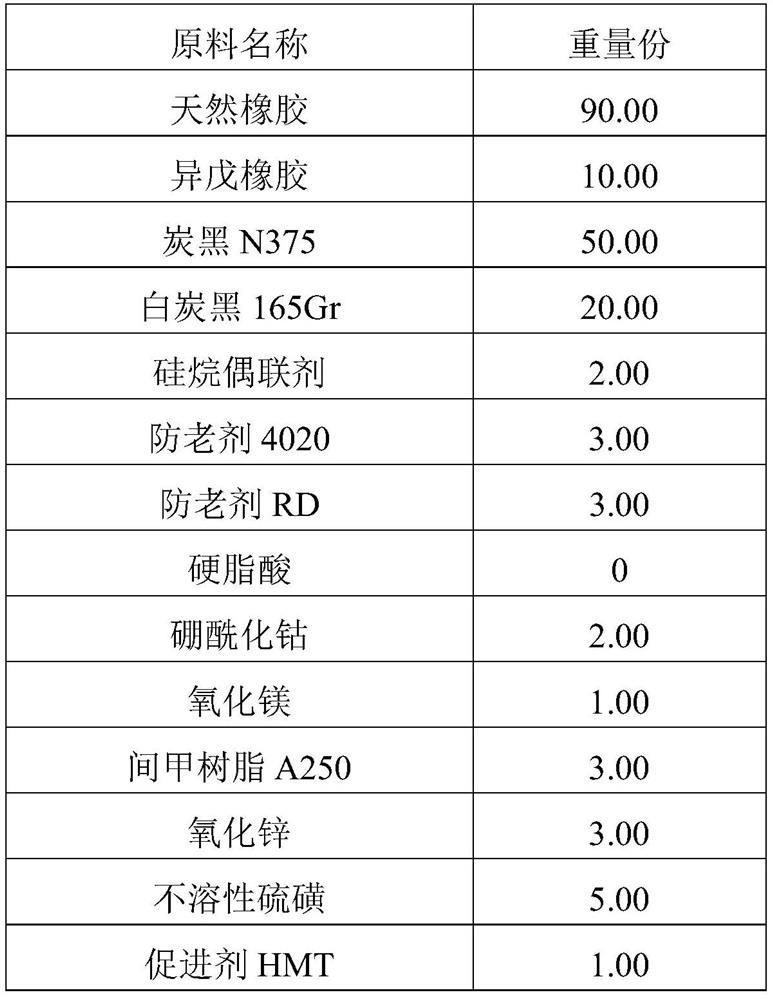

[0056] Embodiment 3 The formula of high-performance cord rubber for tires is as shown in table 4:

[0057] Table 4 Example 3 Cord Glue Formula

[0058]

[0059]

[0060] According to the formula in Table 4, the cord rubber is prepared by the following method:

[0061] (1) One-stage mastication: Weigh each component of the corresponding weight portion, start the internal mixer, set the rotor speed of the internal mixer to 50rpm, the mixing pressure to 15MPa, the cooling water temperature to 35°C, and the rotor temperature to 40°C. Then add natural rubber and isoprene rubber, masticate for 40 seconds to lift up the top bolt, stay for 15 seconds to press the top bolt, lift the top bolt at the mixing temperature to 150°C, reduce the speed to 35rpm, stay for 20 seconds to press the top bolt, Wait until the temperature reaches 170°C to remove the glue, and get a piece of plain glue;

[0062] (2) Second-stage master mixing: Start the internal mixer, set the rotor speed of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com