Heavy oil lightening method

It is a light and heavy oil technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrogenation process, etc. It can solve the problems of limited industrial application, limited industrial application of suspended bed hydrogenation process, and high operating pressure. The operating pressure and other conditions are not harsh, which is conducive to industrial production and application, and the effect of easing the operating pressure and other conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

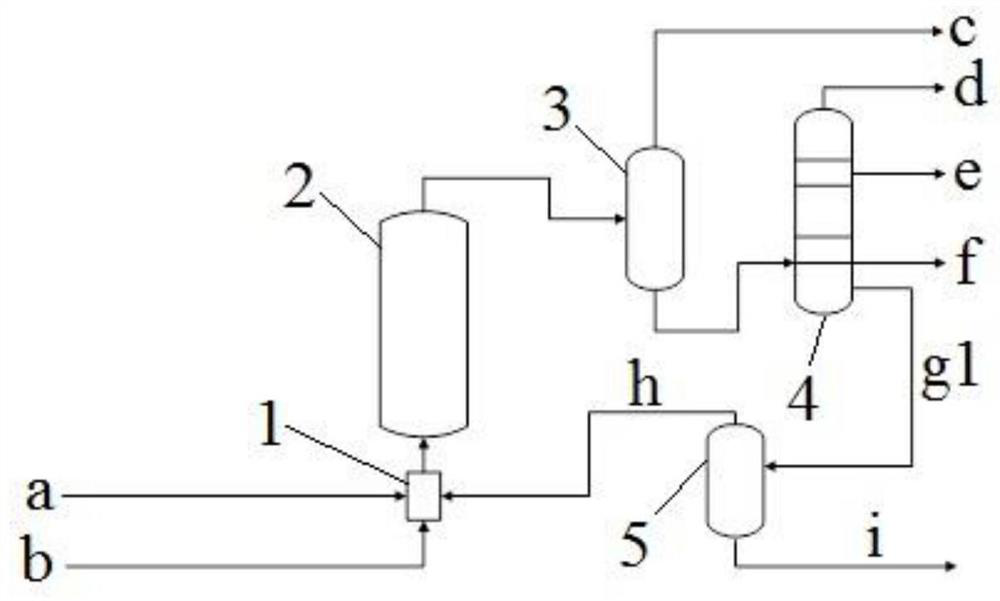

[0045] This embodiment provides a method for lightening heavy oil, such as figure 1 As shown, the hydrogen a and the heavy oil raw material b mixed with catalyst enter the Venturi type micro-element generating device 1 for dispersion treatment, and obtain a micro-element dispersion system in which hydrogen gas is dispersed in the heavy oil raw material with bubbles with an average size not greater than 500 microns; The micro-dispersion system enters the hydrogenation reactor 2 from the top of the hydrogenation reactor to carry out the hydrogenation reaction (the hydrogenation reaction system in the hydrogenation reactor is a dispersion system in which hydrogen gas is dispersed in the oil phase with bubbles no larger than 500 microns) , to obtain the hydrogenation reaction product; the hydrogenation reaction product enters the gas-liquid separator 3 for gas-liquid separation, and obtains the gas phase component (the mixed gas c of cracked gas and hydrogen) and the liquid phase c...

Embodiment 2

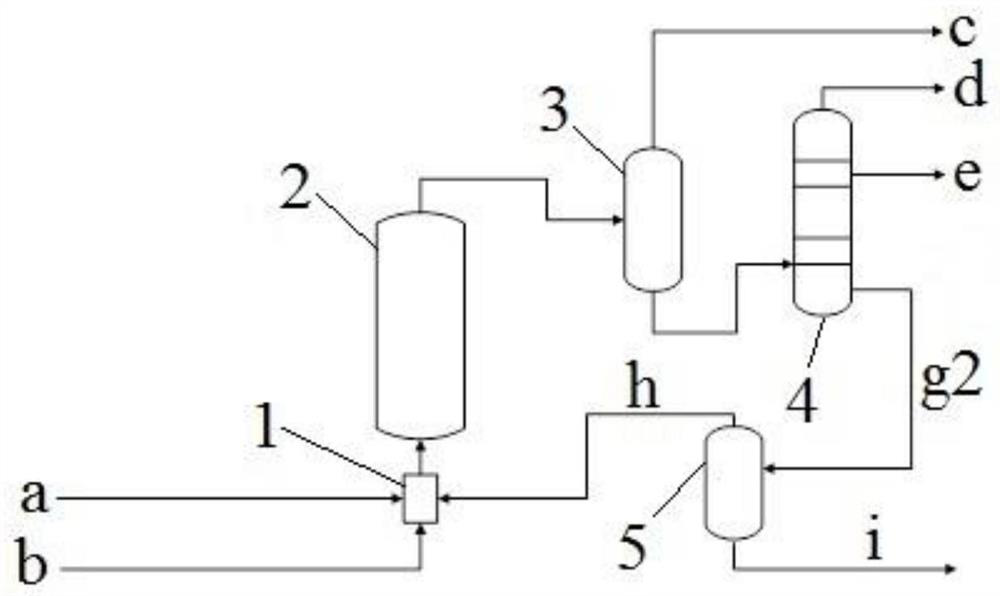

[0047] Such as figure 2 As shown, the difference between the heavy oil lightening method provided in this example and Example 1 is that the liquid phase components enter the distillation tower 4 for fractional distillation to obtain gasoline fraction d at 350°C g2. All the other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com