Para-aramid lithium battery diaphragm and preparation method thereof

A lithium battery separator and para-aramid technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problem of para-aramid being insoluble in polar solvents, and improve cycle performance and heat resistance. , the effect of increasing the energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

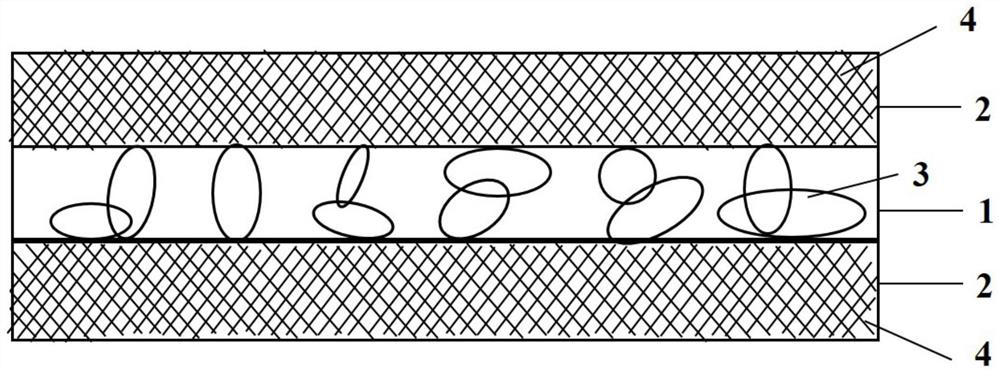

[0029] A preparation method of para-aramid lithium battery separator, comprising the following steps:

[0030] Step 1, the preparation of wet-process aramid porous membrane layer 1: add a cosolvent in an organic solvent under nitrogen protection, dissolve p-phenylenediamine, slowly add terephthaloyl chloride to react while stirring, and react in ice It is carried out in a water bath, and after reacting for 30 minutes, a neutralizing agent is added for neutralization to obtain a para-aramid polymerization solution with a concentration of 0.5-10wt / %. Pour the above-mentioned para-aramid polymerization solution on a glass plate, scrape the film with a scraper, put it in a water bath for phase inversion film formation, take it out, dry it in a 60°C drying oven for 1 hour, and take it out to obtain a wet-process aramid Porous film layer.

[0031] Step 2. Preparation of the aramid nanofiber layer: add a cosolvent and a modifier to an organic solvent under nitrogen protection, disso...

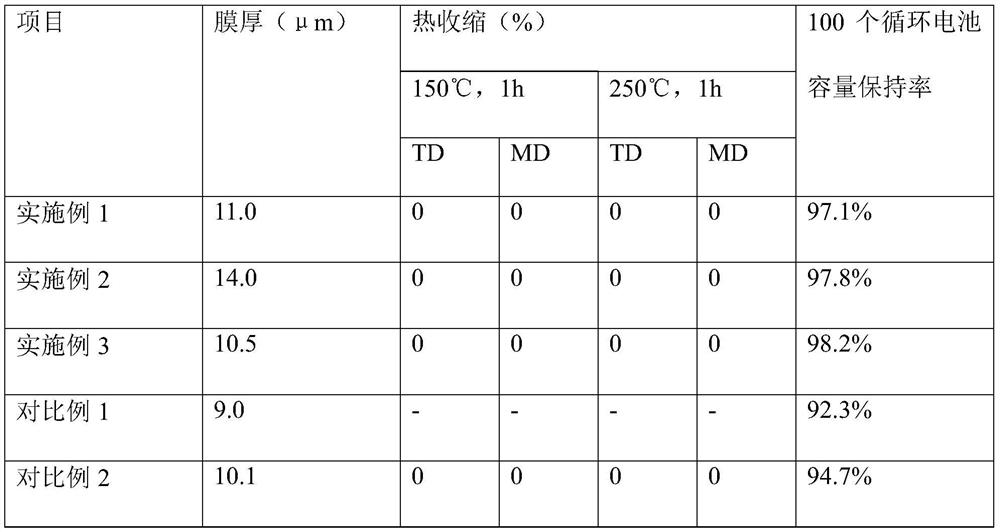

Embodiment 1

[0035] Add CaCl to 30 ml of NMP under nitrogen protection 2 , dissolve 1.0814g p-phenylenediamine, react in an ice-water bath, slowly add 2.1317g terephthaloyl dichloride while stirring, add 0.56g potassium hydroxide to neutralize after reacting for 30min, and obtain a concentration of 10wt / % p-phenylenediamine Aramid polymer solution. Pour the above polymerization solution on a glass plate, scrape the film with a scraper, put it in a water bath for phase inversion film formation, take it off, put it in a drying oven at 60°C for 1 hour, and take it out to obtain a wet-process film with a thickness of 10 μm. Aramid porous membrane layer.

[0036] Under the condition of nitrogen protection, add LiCl in 150ml of DMAc, add 0.0003g of polyethylene glycol, dissolve 1.0814g of p-phenylenediamine, then slowly add 1.9896g of terephthaloyl dichloride to react while stirring, and react in ice Carry out in a water bath, add 100ml DMAc after reacting for 30min, break the gel of the mixtu...

Embodiment 2

[0038] Add CaCl to 50ml of NMP under nitrogen protection 2, dissolve 1.0814g p-phenylenediamine, react in an ice-water bath, slowly add 2.0708g terephthaloyl chloride while stirring, add 0.40g sodium hydroxide to neutralize after reacting for 30min, and obtain a concentration of 6wt / % p-phenylenediamine Aramid polymer solution. Pour the above polymerization solution on a glass plate, scrape the film with a scraper, put it in a water bath for phase inversion film formation, take it out, put it in a drying oven at 60°C for 1 hour, and take it out to obtain a wet-process film with a thickness of 8 μm. Aramid porous membrane layer.

[0039] Add CaCl to 20 ml of NMP under nitrogen protection 2 , add 0.6g of terminal methyl polyoxyethyl ether, dissolve 1.0814g of p-phenylenediamine, then slowly add 2.0708g of terephthaloyl chloride to react while stirring, the reaction is carried out in an ice-water bath, after 30min of reaction, add 10ml of DMAc, The gel of the mixture was broke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com