Method for resource utilization of sludge biochar

A technology of recycling and biochar, applied in chemical instruments and methods, cement mixing devices, manufacturing tools, etc., can solve the problems of complex biochar preparation process, poor applicability, and high cost, and achieve good economic and environmental benefits , Low product cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The biochar used in this test was taken from the biochar formed by pyrolysis of sludge from a sewage treatment plant in Xiamen City at 600 °C, and was used as brick-making material after being crushed and screened; standard 42.5 grade ordinary Portland cement was used; Ordinary fine-grained river sand; water for ingredients is ordinary tap water.

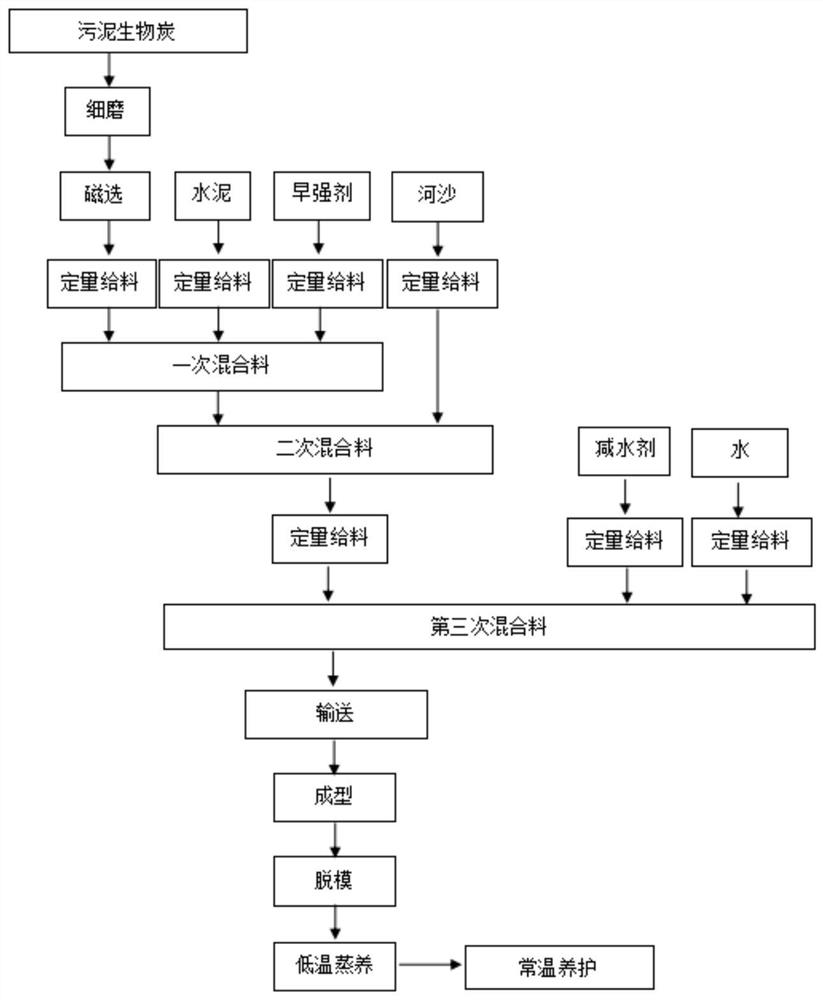

[0034] Fine grinding: finely grind the above-mentioned biochar to <100 mesh and magnetically separate to obtain ferromagnetic material and biochar micropowder without iron; among them, the ferromagnetic material is used as smelting raw material or chemical raw material.

[0035] Preparation of the primary mixture: Dry premix the above iron-free biochar micropowder with cement and early-strength agent to obtain the pre-mixture; the early-strength agent is calcium chloride, and its addition ratio is 1%.

[0036] Secondary mixture preparation: add river sand to the premixed material obtained above, and perform secondary mixing t...

Embodiment 2

[0049] Embodiment 2: Existing speciation analysis of heavy metals in biochar micropowder and solid brick

[0050] Existing forms of heavy metals are closely related to their hazards. At present, the BCR continuous extraction method is the main test method for the form of heavy metals in biochar and its products. Among them, the F1 state is a weak acid extraction state, which mainly refers to the existence of adsorption on the particle surface or in the form of carbonate binding, and is easily affected by the type of ions in the water body and the adsorption and desorption; the F2 state is a reducible state , mainly refers to the form combined with iron-manganese oxides, which is relatively unstable under anoxic or anaerobic conditions; F3 state is an oxidizable state, mainly referring to heavy metals combined with organic matter, sulfide, etc. Form, which can be degraded under certain conditions and thus be used by organisms; F4 state is a residue state, mainly referring to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com