Salt mud curing material as well as preparation method and application thereof

A technology for solidifying materials and salt mud, applied in the field of salt mud solidifying materials and their preparation, can solve problems such as shortage, damage to chemical corrosion resistance, and easy corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] For the returned salt mud after crude salt refining in a coastal salt field in North China, the moisture content after air drying is about 5%. Using 94 parts of the above-mentioned salt mud, add 3 parts of sand and stones with a particle size less than 3mm and 5 parts of aluminate cement, stir for 1 min, and mix well to obtain a mixture; take 0.02% of the total mass of the mixture and reduce Water agent, diluted 30 times with water, added to the mixture, stirred evenly, formed by ordinary rolling, added water every 12 hours for curing, a total of 7 days of curing, to obtain a rectangular brick structure with a length of 24cm, a width of 11.5cm, and a height of 5.6cm body. Then unconfined compressive strength, continuous seawater immersion, compactness, ion leaching test and immersion resistance test were carried out.

Embodiment 2

[0041] The difference from Example 1 is that a 200-ton brick making machine is used for compression molding.

Embodiment 3

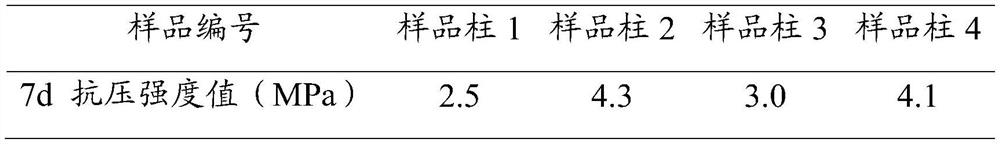

[0045] Unconfined compressive strength, continuous seawater immersion and compactness test results:

[0046] For the bricks of Example 1, the 7-day unconfined compressive strength is 2.8 MPa; for the bricks of Example 2, the 7-day unconfined compressive strength is 18.2 MPa, and the 28-day strength reaches 27 MPa. The compactness of the bricks in Example 1 and Example 2 is 95%. After 7 days of continuous seawater immersion test, there is no any collapse on the surface, and it is still relatively smooth and smooth.

[0047] Anti-immersion performance test results:

[0048] The bricks prepared in Example 2 were soaked continuously in water for 30 days, wherein the ratio of the mass of bricks to the volume of water was 1kg:10L. The results show that there is no corrosion, collapse and holes on the surface of the bricks, and the corners are relatively hard without collapse.

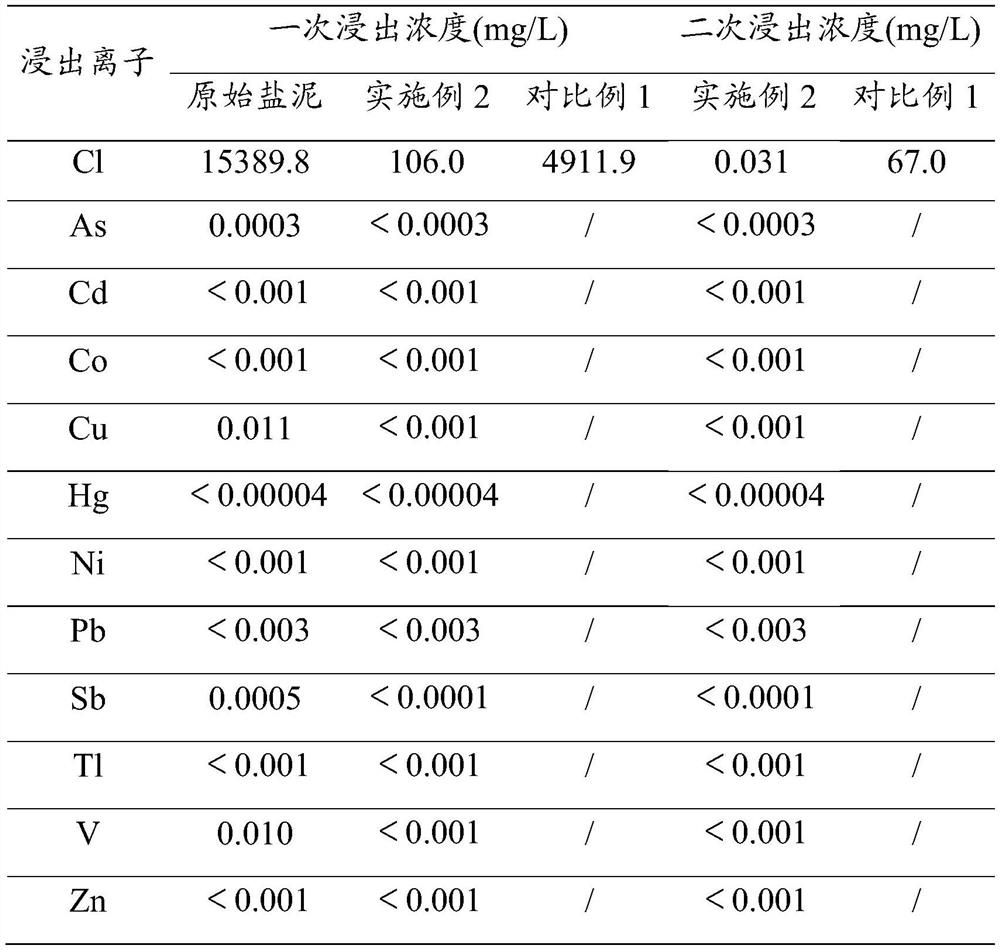

[0049] Ion leaching experiment results:

[0050] According to "HJ 557-2010", the bricks obtained in Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com