Method and equipment for industrially preparing low-GI lotus root starch

A technology of lotus root powder and equipment, applied in the field of industrialized preparation of low GI lotus root powder, can solve the problems of increased cost of low GI lotus root powder, affecting the RS characteristics of lotus root powder, poor quality of lotus root powder, etc., to increase the amorphous area, avoid non-enzymatic browning, Improvement of slow digestion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

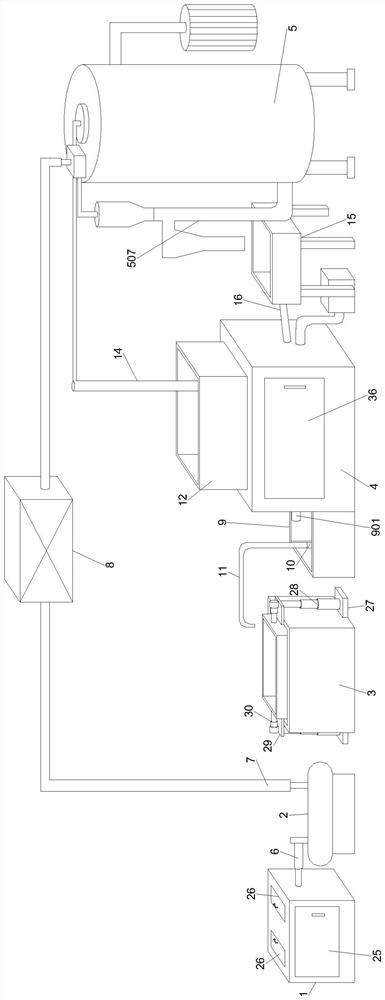

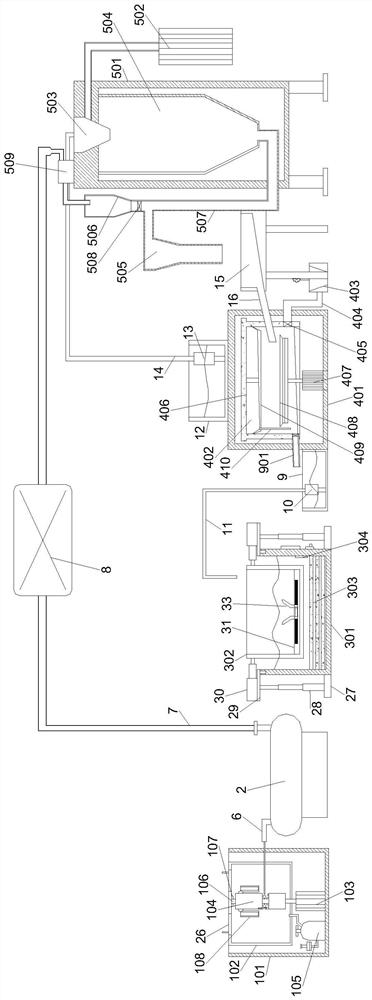

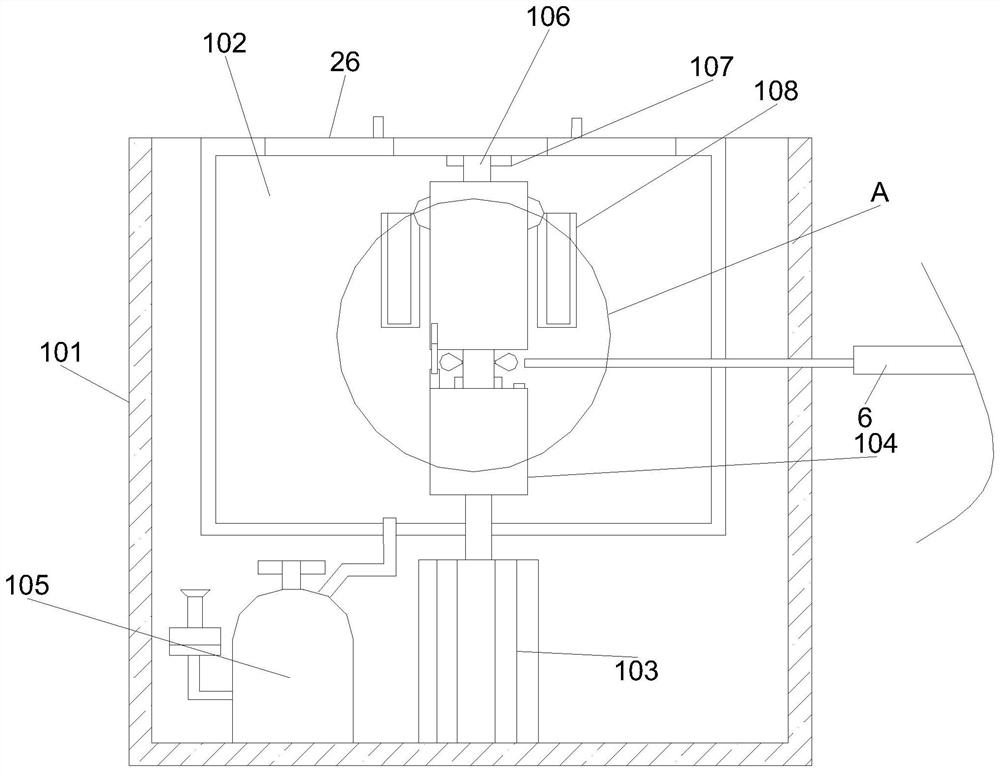

[0065] Such as figure 1 and figure 2 The shown a kind of industrialization prepares the equipment of low GI lotus root starch, comprises the freezing separator 1, air compressor 2, constant temperature water bath box 3, vacuum drying box 4 and spray drier 5 that are arranged successively, and freezing separator 1 includes freezing separator 1. Casing 101, freezing bin 102, first driving motor 103 and rotating connecting column 104, the bottom of freezing bin 102 is provided with such as image 3 As shown in the micro compressor 105, the first drive motor 103 is arranged below the freezer 102, the output end of the first drive motor 103 extends to the insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com