Biodegradable mulching film suitable for long-period growing plants

A biodegradable, long-term technology, applied to plant protection covers, etc., to achieve the effects of increased yield and harvest, simple manufacturing method, and cheap and easy-to-obtain components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

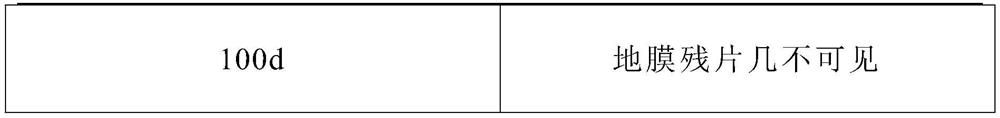

Examples

Embodiment 1

[0023] This embodiment provides a biodegradable mulch film suitable for long-term growth plants, including 80 parts by mass of PCL resin, 10 parts of polyvinyl alcohol, 5 parts of plant fiber, 15 parts of calcium carbonate, 0.1 part of Light stabilizer, 0.1 part of antioxidant, 3 parts of modified nano-montmorillonite, 1 part of paraffin and 0.5 part of 2-ethylhexanol acetate.

[0024] Wherein, the light stabilizer is light stabilizer 944; the antioxidant is antioxidant 1010; the plant fiber is bamboo fiber.

[0025] The modified nano-montmorillonite is prepared by the following method: adding nano-montmorillonite to an aqueous solution of sodium hydroxide with a pH value of 8, heating at 80°C for 20 minutes, filtering while hot, drying at 80°C for 30 minutes after filtration, and cooling for 5 minutes after drying to 10°C to obtain modified nano-montmorillonite.

[0026] Light stabilizer 944 is also known as hindered amine light stabilizer HS-944, and its molecular formula i...

Embodiment 2

[0029] This embodiment provides a biodegradable mulch film suitable for long-term growth plants, including 60 parts by mass of PCL resin, 20 parts of polyvinyl alcohol, 10 parts of plant fiber, 25 parts of calcium carbonate, 1 part of Light stabilizer, 1 part of antioxidant, 7 parts of modified nano-montmorillonite, 2 parts of paraffin and 2 parts of 2-ethylhexanol acetate.

[0030] Among them, the light stabilizer is light stabilizer 944; the antioxidant is antioxidant 1010; the plant fiber is a mixture of rice straw and corn stalks at a mass ratio of 1:1.

[0031] The modified nano-montmorillonite was prepared by the following method: adding nano-montmorillonite to an aqueous solution of sodium hydroxide with a pH value of 10, heating at 90°C for 40 minutes, filtering while hot, drying at 100°C for 60 minutes after filtration, and cooling for 3 minutes after drying to 5°C to obtain modified nano-montmorillonite.

Embodiment 3

[0033] This embodiment provides a biodegradable mulch film suitable for long-term growth plants, including 70 parts by mass of PCL resin, 15 parts of polyvinyl alcohol, 8 parts of plant fiber, 20 parts of calcium carbonate, 0.5 parts of Light stabilizer, 0.5 parts of antioxidant, 5 parts of modified nano-montmorillonite, 1.5 parts of paraffin and 1 part of 2-ethylhexanol acetate.

[0034] Wherein, the light stabilizer is light stabilizer 944; the antioxidant is antioxidant 1010; the plant fiber is cotton fiber.

[0035] The modified nano-montmorillonite is prepared by the following method: add the nano-montmorillonite to the sodium hydroxide aqueous solution with a pH value of 9, heat at 85°C for 30 minutes, filter while it is hot, dry at 90°C for 45 minutes after filtration, and cool for 4 minutes after drying to 8°C to obtain modified nano-montmorillonite.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap