Preparation method of compact and thick thermal barrier coating

A thermal barrier coating, dense technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the uncertainty of crack growth direction, low bonding strength, coating bonding strength and low service life, etc. problems, to achieve the effect of improving high temperature service stability, improving service temperature and toughness, and uniform and controllable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a dense and thick thermal barrier coating, comprising:

[0029] S1 obtains ceramic powder prepared from nano raw material as raw material powder.

[0030] In this embodiment, nanostructured ceramic powder is used as the raw material powder of the dense and thick thermal barrier ceramic coating, wherein the purity of the ceramic powder used is ≥99.5%, and the impurity content is ≤0.5%, preferably, the purity of the ceramic powder is ≥99.9%. , impurity content ≤ 0.1%. The primary particle size of the ceramic powder used is 1-100 nm, preferably, the particle size is 5-60 nm.

[0031] In this embodiment, the composition of the ceramic powder includes one or more of zirconia, yttrium oxide, dysprosium oxide, ytterbium oxide, gadolinium oxide, lanthanum oxide, cerium oxide, and magnesium oxide.

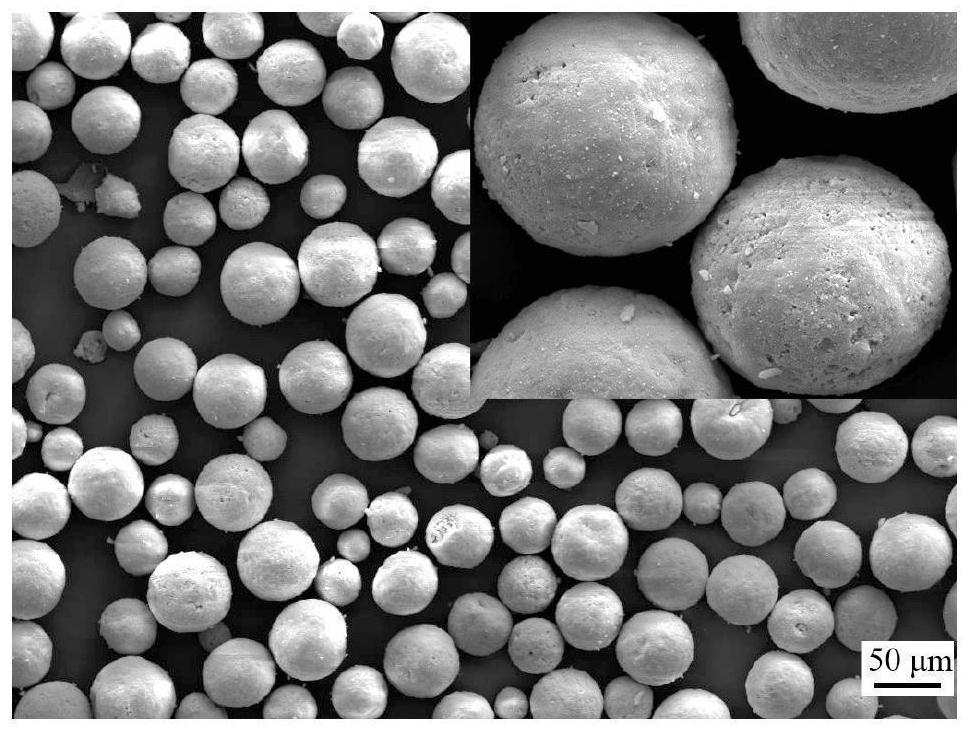

[0032] S2 granulating the ceramic powder, and plasma sintering the granulated ceramic powder to obtain a coating raw material.

[003...

Embodiment 1

[0043] In step S1, high-purity yttria-doped stabilized zirconia powder is used as the raw material powder of the dense thermal barrier coating. Wherein, the purity of the ceramic powder is ≥99.9%, and the primary particle size of the ceramic powder is 15-53 nm.

[0044] Step S2, granulating the coating material powder to obtain the original powder and then performing plasma sintering.

[0045]In step S3, the ceramic powder is graded according to a specific particle size ratio, and fully and evenly mixed to obtain a ceramic thermal barrier coating powder raw material with unimodal particle size distribution characteristics. Among them, the peak value of the medium particle size is 5-38 μm, which accounts for 80 wt%, and the fine powder and coarse powder account for 20 wt%.

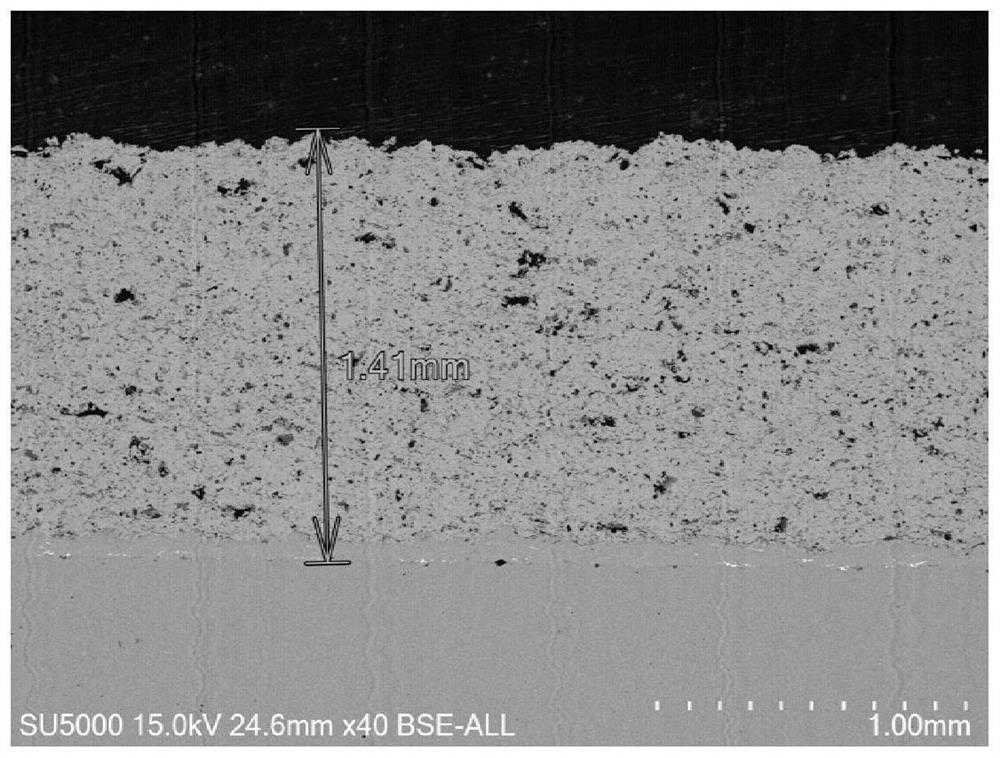

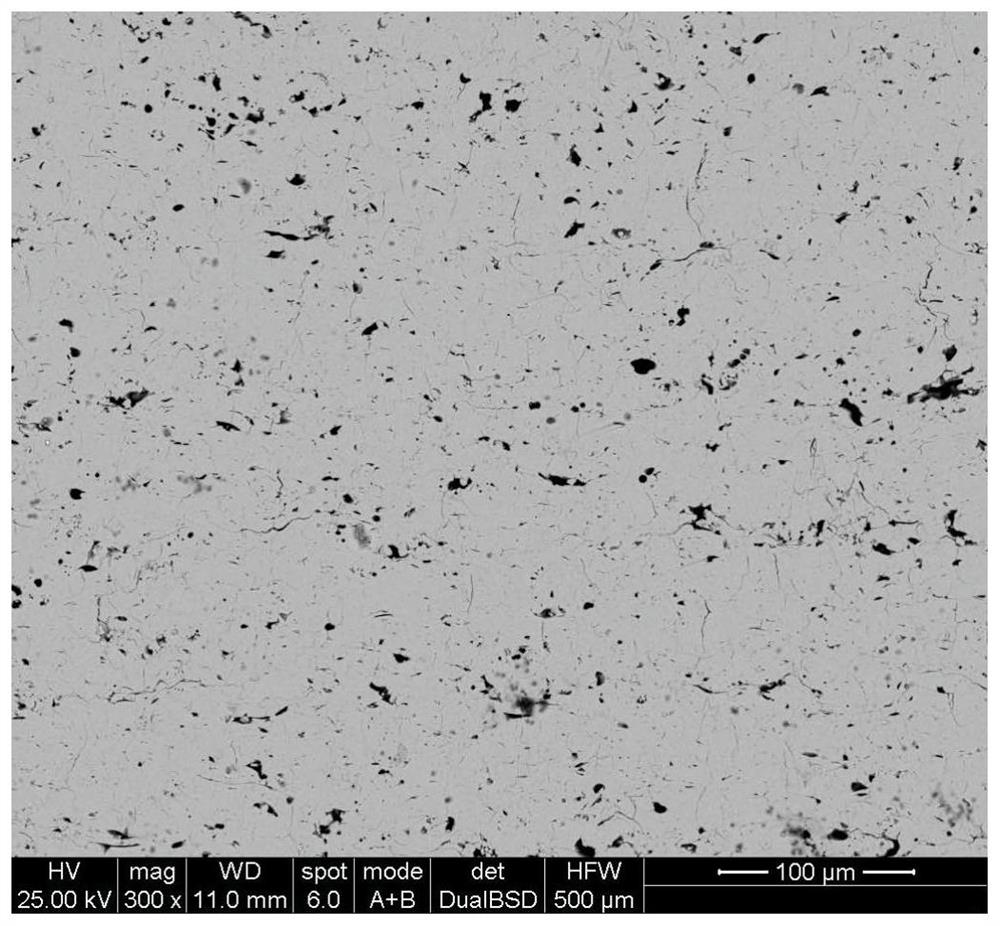

[0046] Step S4, using the powder obtained in step S3 as the raw material, by adjusting the spraying distance, spraying power, powder feeding amount, etc., the deposition pressure in this process is control...

Embodiment 2

[0051] In step S1, high-purity ytterbium oxide, cerium oxide, and gadolinium oxide-doped stabilized zirconia are used as raw material powders for the dense thermal barrier coating. Wherein, the purity of the ceramic powder is ≥99.9%, and the primary particle size of the ceramic powder is 25-50 nm.

[0052] Step S2, granulating the coating material powder to obtain the original powder and then performing plasma sintering.

[0053] In step S3, the ceramic powder is graded according to a specific particle size ratio, and fully and evenly mixed to obtain a ceramic thermal barrier coating powder raw material with unimodal particle size distribution characteristics. Among them, the peak of the medium particle size is 5-38 μm, accounting for 70wt%, and the fine powder and coarse powder accounting for 30wt%.

[0054] Step S4, using the powder obtained in step S3 as the raw material, by adjusting the spraying distance, spraying power, powder feeding amount, etc., the deposition pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com