Full-bio-based high-durability super-hydrophobic cotton fabric and preparation method thereof

An all-biological, cotton fabric technology, applied in plant fibers, textiles and papermaking, fiber processing, etc., can solve the problems affecting the inherent properties of cotton fabrics, such as air permeability and softness, low water-oil separation efficiency, and changes in inherent properties of full fabrics, etc. problems, to achieve the effects of improved safety and bio-environmental protection, excellent water-oil separation ability, and high-efficiency water-oil separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

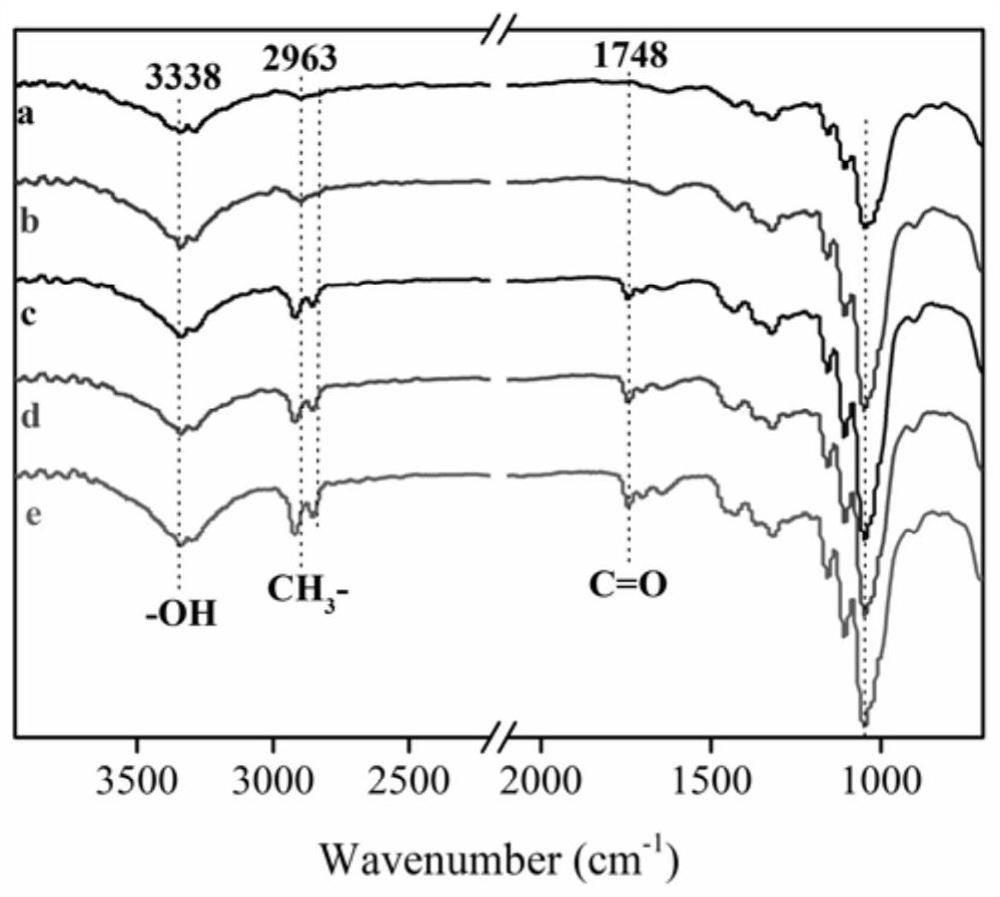

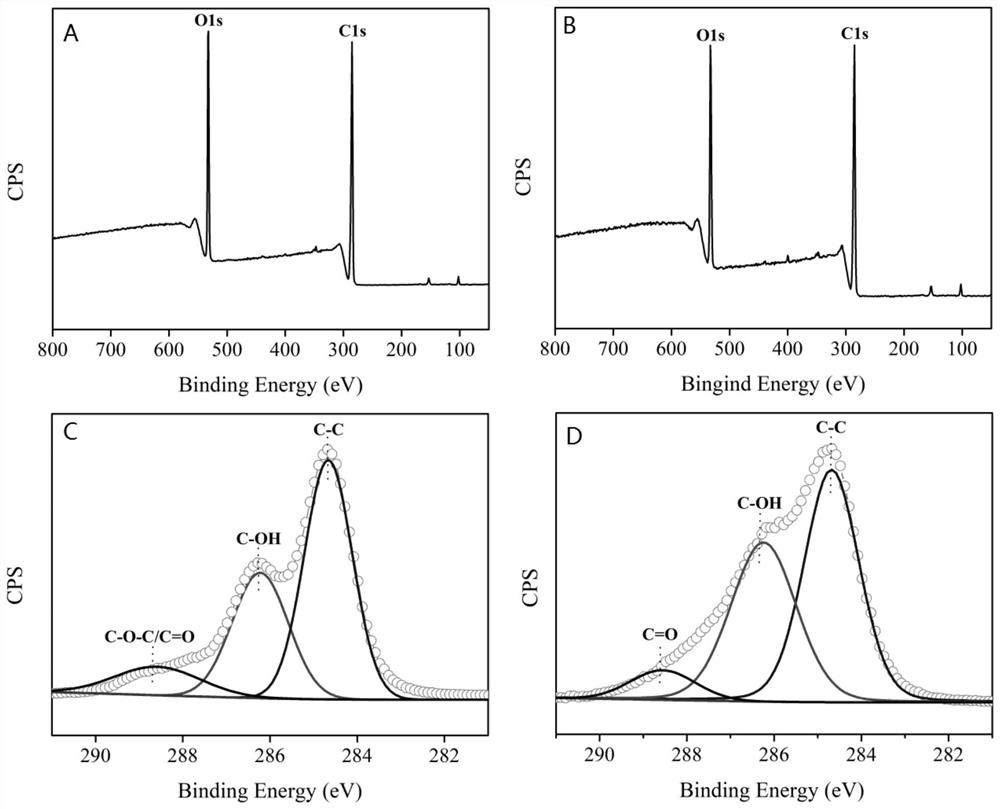

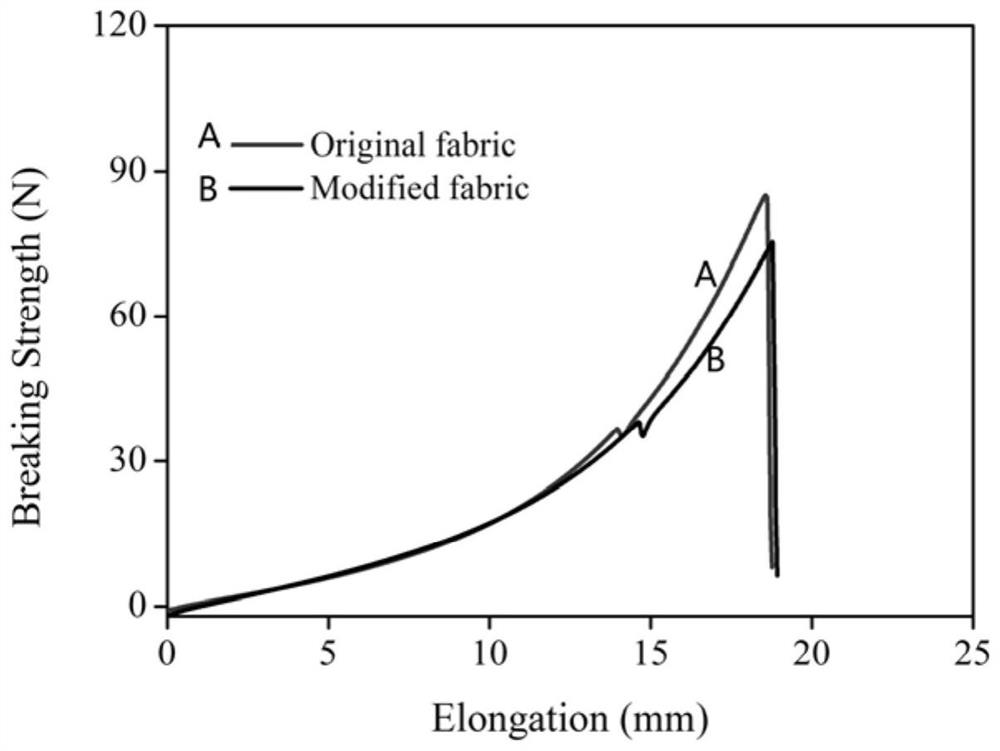

[0034] A fully bio-based high-durability super-hydrophobic cotton fabric, including cotton fabric and a super-hydrophobic finishing layer grafted thereon, the thickness of the super-hydrophobic finishing layer is 0.5 microns, and the content accounts for 4.9% of the total mass of the fabric.

[0035] Its preparation method comprises the following steps:

[0036] (1) A mixture of choline chloride (139.62g, 1.00mol) and oxalic acid hydrate (126.07g, 1.00mol) was heated at 110°C for 2h to obtain a deep eutectic solvent; the original cotton fabric (5cm×5cm) Immerse in the prepared eutectic solution, etch at 60°C for 2h;

[0037] (2) The cotton fabric after etching is immersed in the ethanol solution containing epoxy soybean oil, sebacic acid and 1,8 diazabicyclo[5.4.0]undec-7-ene for 30min, then at 150 ℃ oven for 3 hours; the concentrations of epoxidized soybean oil, sebacic acid and 1,8-diazabicyclo[5.4.0]undec-7-ene in ethanol solution were 2%, 0.32%, 0.032%, respectively %; ...

Embodiment 2

[0041] A fully bio-based high-durability super-hydrophobic cotton fabric, comprising a cotton fabric and a super-hydrophobic finishing layer grafted thereon, the thickness of the super-hydrophobic finishing layer is 0.6 microns, and the content accounts for 6.5% of the total mass of the fabric.

[0042] Its preparation method comprises the following steps:

[0043] (1) with step (1) in embodiment 1;

[0044] (2) The cotton fabric after etching is immersed in the ethanol solution containing epoxy soybean oil, sebacic acid and 1,8 diazabicyclo[5.4.0]undec-7-ene for 30min, then at 150 ℃ oven for 3 hours; the concentrations of epoxidized soybean oil, sebacic acid and 1,8-diazabicyclo[5.4.0]undec-7-ene in ethanol solution were 3%, 0.48%, 0.048%, respectively %;

[0045] (3) Soak the cotton fabric treated in step (2) in ethanol solution containing stearic acid, the concentration of stearic acid in ethanol solution is 2.84%, react at 25°C for 3h, then continue drying at 80°C In 10...

Embodiment 3

[0048] A fully bio-based high-durability super-hydrophobic cotton fabric, comprising a cotton fabric and a super-hydrophobic finishing layer grafted thereon, the thickness of the super-hydrophobic finishing layer is 0.7 microns, and the content accounts for 7.6% of the total mass of the fabric.

[0049] Its preparation method comprises the following steps:

[0050] (1) with step (1) in embodiment 1;

[0051] (2) The cotton fabric after etching is immersed in the ethanol solution containing epoxy soybean oil, sebacic acid and 1,8 diazabicyclo[5.4.0]undec-7-ene for 30min, then at 150 ℃ oven for 3 hours; the concentrations of epoxidized soybean oil, sebacic acid and 1,8-diazabicyclo[5.4.0]undec-7-ene in ethanol solution were 4%, 0.64%, 0.064%, respectively %;

[0052] (3) Soak the cotton fabric treated in step (2) in ethanol solution containing stearic acid, the concentration of stearic acid in ethanol solution is 2.84%, react at 25°C for 3h, then continue drying at 80°C In 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com