Alkane isomerization catalyst and preparation method thereof

A kind of alkane isomerization and catalyst technology, which is applied in the direction of catalyst activation/preparation, isomerization hydrocarbon production, physical/chemical process catalyst, etc. It can solve the problems of low operating cost, high energy consumption of operating cost, and large investment, and achieves Precise control of load, avoiding side effects, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The catalyst prepared by the preparation method of the present invention may also contain other components or a mixture of these components, which can be used alone or together as a catalyst modifier to improve the activity, selectivity or stability of the catalyst. Some known catalyst modifiers include Rh, In, Co, Ni, Fe, W, Mo, Cr, Bi, Sb, Zn, Cd, and Cu. Catalytically effective amounts of these components may be added to the support material in any suitable manner after or during its preparation, or to the catalyst before, simultaneously with or after the introduction of the other components.

[0042] The present invention also provides an alkane isomerization catalyst prepared by the method provided in the present invention.

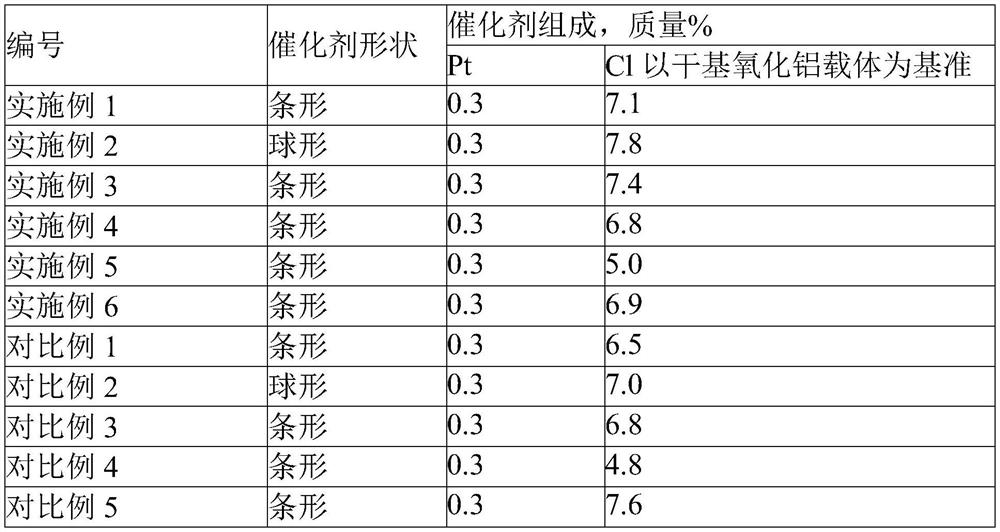

[0043] In the prepared alkane isomerization catalyst, the content of group VIII metals is 0.01-5% by mass, preferably 0.05-1.5% by mass; the content of chlorine is 3.0-10% by mass, based on the dry alumina carrier. Preferably it is 3.5-8.5 ma...

Embodiment 1

[0049] This example is used to illustrate the preparation method of the alkane isomerization catalyst of the present invention.

[0050] (1) the aluminum hydroxide powder of 100g (Germany, the SB powder that Condea company produces, aluminum oxide content is 75 mass %) and deionized water are mixed according to the weight ratio of water and aluminum hydroxide powder 1:1.6, then add 7mL of dilute nitric acid with a volume ratio of 1:1 was kneaded, then extruded, dried at 120°C for 2 hours, and then calcined at 550°C for 4 hours to obtain γ-alumina carrier S1.

[0051] (2) impregnating the alumina support S1 prepared in step (1) with an impregnating solution containing chloroplatinic acid, hydrochloric acid and trichloroacetic acid to obtain an impregnated support. The volume ratio of the impregnating solution to the alumina carrier S1 is 1.8, and the impregnating time is 24 hours. Compared with the dry alumina carrier S1, the contents of hydrochloric acid (calculated as HCl), t...

Embodiment 2

[0056] This example is used to illustrate the preparation method of the alkane isomerization catalyst of the present invention.

[0057] (1) Take 100g of aluminum hydroxide powder and an appropriate amount of deionized water to make the liquid / solid mass ratio 2.0, and stir to make it slurry. Add the dilute nitric acid of 1:1 (volume ratio), the SB powder that its addition amount is 7.5ml / 100g, add the urea of 30g simultaneously, stir 1h, then add the kerosene of 30g and the fatty alcohol polyoxyethylene ether of 3g and stir 1h, Then drop the ball into the oil ammonia column to form. The wet bulb was solidified in ammonia water for 1 hour, then filtered, rinsed with deionized water 2-3 times, dried at 60°C for 6 hours, 120°C for 10 hours, and then calcined at 550°C for 1 hour to obtain γ-alumina carrier S2.

[0058] (2) impregnating the alumina support S2 prepared in step (1) with an impregnating solution containing chloroplatinic acid, hydrochloric acid and trichloroacetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com