Long-acting antibacterial and anticoagulant material as well as preparation method and application thereof

A long-acting, base material technology, applied in the field of medical materials, can solve the problems of easy thrombosis and infection, insufficient anticoagulant performance, and insufficient antibacterial performance, and achieve the effect of long release cycle and prolonged release time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Embodiments of the present invention provide a method for preparing a long-acting antibacterial and anticoagulant material, comprising the following steps:

[0038] S1. Preparation of Cu-MOFs coating

[0039] A Cu-MOFs coating is formed on the substrate, and the Cu-MOFs nanoparticles containing amino groups can be used to introduce Cu-MOFs onto the substrate with functional groups such as quinone groups, epoxy groups, and isocyanate groups.

[0040] In the actual operation process, the preparation method of Cu-MOFs coating includes: mixing Cu-MOFs nanoparticles containing amino groups with a solution with reactive groups to obtain the coating solution, and then by dip coating or spin coating A Cu-MOFs coating is formed on the surface of the substrate; wherein, the reactive group is selected from at least one of quinone group, epoxy group and diisocyanate. The reactive group can be one kind or several kinds, which is not limited here.

[0041] Specifically, Cu-MOFs nan...

Embodiment 1

[0060] This embodiment provides a method for preparing a long-acting antibacterial and anticoagulant material, and the specific steps are as follows:

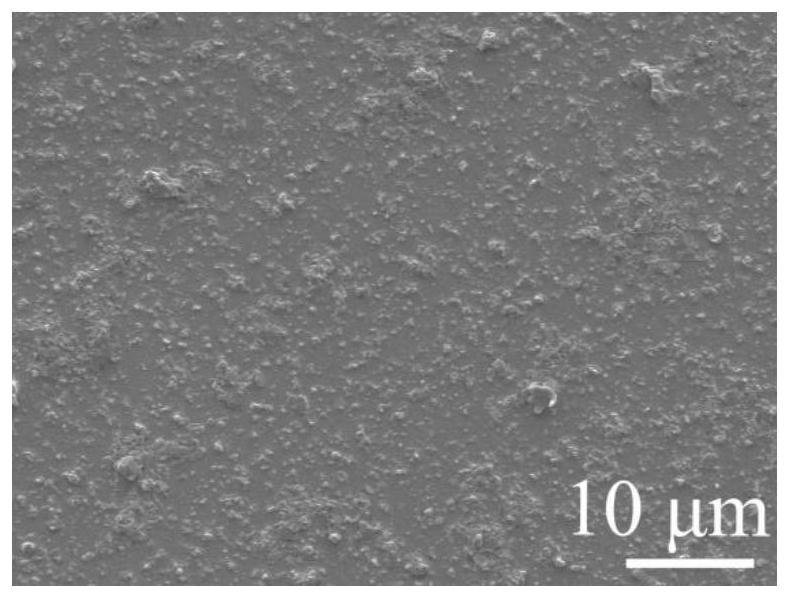

[0061] (1) Cut TPU into squares of 1cm×1cm, ultrasonically clean them with ethanol and distilled water for 10min, and dry them at 50°C for later use. Ultrasonic dispersion of the synthesized Cu-MOFs nanoparticles in 2 mg / mL Tris (pH=8.5) solution of dopamine with quinone groups to form a mixed solution of Cu-MOFs nanoparticles with a concentration of 4.5 mg / mL; the sample was placed in the configuration In a good mixed solution of Cu-MOFs / dopamine, it was deposited at 37°C for 12 hours and then ultrasonically cleaned; three layers were deposited repeatedly to obtain a mixed coating of polydopamine and Cu-MOFs nanoparticles, which was denoted as Cu-MOFs-PDA.

[0062] (2) Transfer the Cu-MOFs-PDA sample to the high-pressure reactor and pump the vacuum to 0.1MPa for 60min, then close the vacuum valve, open the nitric oxide main va...

Embodiment 2

[0064] This embodiment provides a method for preparing a long-acting antibacterial and anticoagulant material, and the specific steps are as follows:

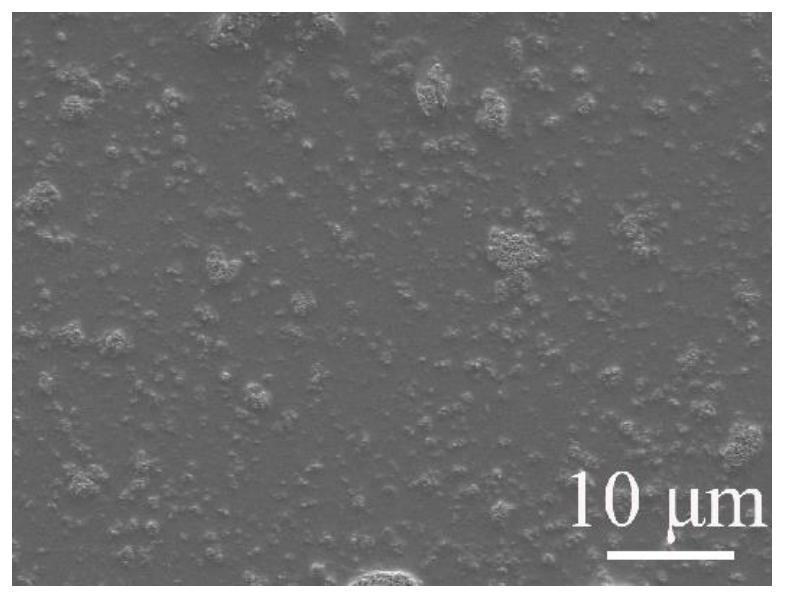

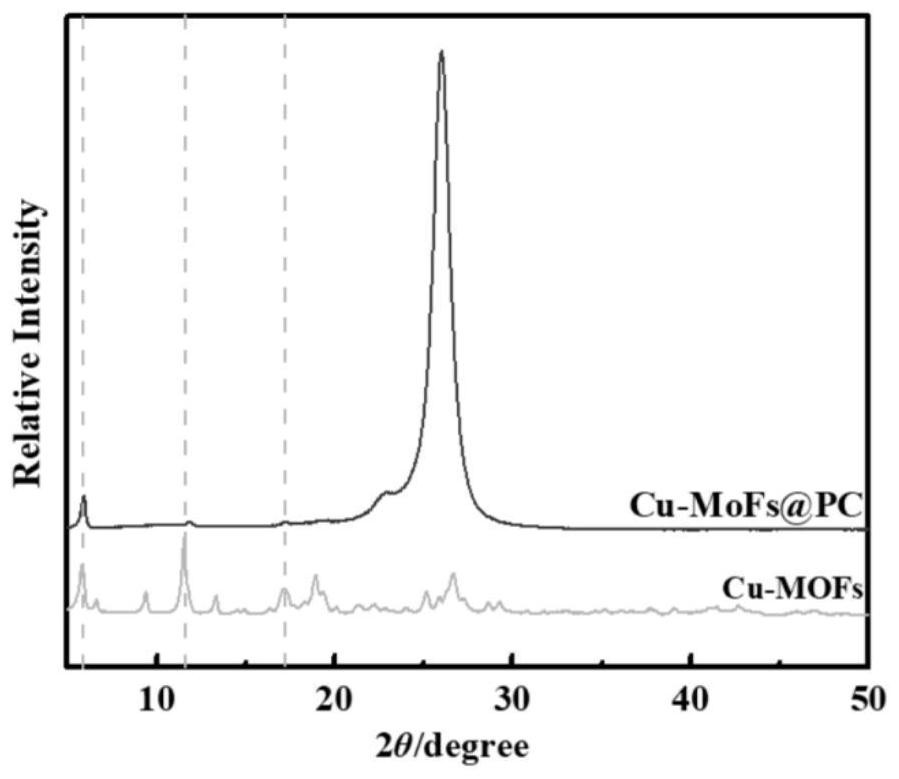

[0065] (1) Cut TPU into squares of 1cm×1cm, ultrasonically clean them with ethanol and distilled water for 10min, and dry them at 50°C for later use. The synthesized Cu-MOFs nanoparticles were ultrasonically dispersed in the medical coating solution with epoxy groups and diisocyanates to form a mixed solution with a concentration of Cu-MOFs nanoparticles of 4.5 mg / mL. Then use a spin coater to spin-coat 10 layers on the surface of the base material. During each layer of spin-coating, the control speed is 800r / min, and the spin-coating time is 40s to obtain a mixed coating of medical coating and Cu-MOFs nanoparticles. For Cu-MOFs@PC.

[0066] (2) Transfer the Cu-MOFs@PC sample obtained by spin coating to a high-pressure reactor and pump the vacuum to 0.1 MPa for 60 minutes, then close the vacuum valve, open the main valve of ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap