Preparation method of catalyst for catalyzing sulfachloropyridazine sodium in ozonized water

A technology of sulfachloropyridazine sodium and a catalyst, which is applied in the field of catalytic ozonation of wastewater containing sulfachloropyridazine sodium, can solve the problems of low catalytic efficiency and low utilization rate, and achieve high catalytic activity, good stability, and expanded dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Activation treatment of the carrier: first wash with distilled water until neutral, and then put it into a vacuum drying oven and dry at 120° C. for 2 hours. Finally, it was calcined at 200 °C for 2 h in a muffle furnace.

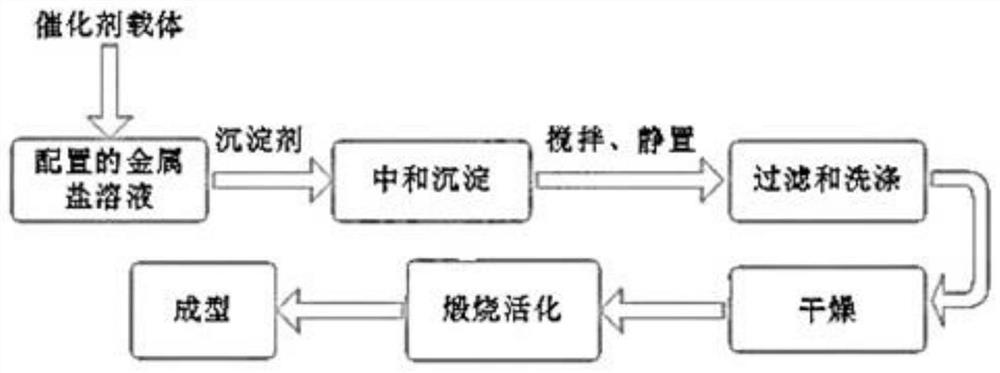

[0040] Preparation of catalyst: prepare Ce-Fe / AC supported metal catalyst by co-precipitation method, take 4.34g Ce(NO 3 ) 3 ·6H 2 O was put into five beakers with 100mL of distilled water, and after the dissolution was complete, add 0.278g, 0.417g, 0.556g, 0.834g, 0.973g, 1.390g FeSO 4 •7H 2 O, configured as a solution with a molar ratio of primary and secondary metals of 1:0.1, 1:0.15, 1:0.2, 1:0.3, 1:0.35, 1:0.5, completely dissolved with a magnetic stirrer, and 10g of activated The carrier was added to 100 mL of metal ion solutions of different concentrations, stirred at 25°C for 4 hours and then left to stand for 2 hours, so that the metal ions were evenly loaded inside the carrier. Then, a certain concentration of NaOH solution was added, ...

Embodiment 2

[0044] Activation treatment of the carrier: first wash with distilled water until neutral, and then put it into a vacuum drying oven and dry at 120° C. for 2 hours. Finally, it was calcined at 200 °C for 2 h in a muffle furnace.

[0045] Catalyst preparation: Ce-Fe-Zn / AC supported metal catalyst was prepared by co-precipitation method, and 4.34g Ce(NO 3 ) 3 ·6H 2 O, 0.556g FeSO 4 •7H 2 O was added to five beakers filled with 100mL of distilled water, and 0.029g, 0.058g, 0.087g, 0.145g, and 0.203g of ZnSO were added after the dissolution was complete. 4 •7H 2 O, configured into three kinds of solutions with metal molar ratios of 1:0.3:0.001, 1:0.3:0.002, 1:0.3:0.003, 1:0.3:0.005, 1:0.3:0.007, using a magnetic stirrer to make it completely dissolve. 10 g of the activated carrier was added to 100 mL of metal ion solutions of different concentrations, stirred at 25° C. for 4 h and then allowed to stand for 2 h, so that the metal ions were evenly loaded inside the carrier. ...

Embodiment 3

[0049] Activation treatment of the carrier: first wash with distilled water until neutral, and then put it into a vacuum drying oven and dry at 120° C. for 2 hours. Finally, it was calcined at 200 °C for 2 h in a muffle furnace.

[0050] The preparation of catalyst: take by weighing 4.34gCe(NO 3 ) 3 ·6H 2 O, 0.556g FeSO 4 •7H 2 O was added to a beaker containing 100mL of distilled water, and after the dissolution was complete, 0.058g of ZnSO was added 4 •7H 2 O, use a magnetic stirrer to dissolve it completely. 10 g of the activated carrier was added to 100 mL of metal ion solutions of different concentrations, stirred at 25° C. for 4 h and then allowed to stand for 2 h, so that the metal ions were evenly loaded inside the carrier. Then, a certain concentration of NaOH solution was added, stirred continuously for 4 hours at 25° C., and then stood still for 24 hours to completely precipitate the loaded metal ions. Wash the filtered catalyst with distilled water until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com