Vanadium phosphorus oxide catalyst as well as preparation method and application thereof

A vanadium phosphorus oxide and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of small specific surface area and pore volume, unsatisfactory conversion rate of reactants and maleic anhydride yield , the problem of uneven particle size distribution of vanadium phosphorus oxide catalyst, to achieve the effect of uniform particle size distribution, avoid particle agglomeration, and control the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

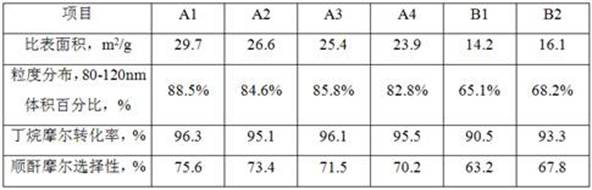

Embodiment 1

[0033]Using a four-necked flask with a stirring and reflux cooling device, add 100g of isobutanol and 25.0g of vanadium pentoxide into the four-necked flask, start stirring, and heat up to 95°C; mix 380g of isobutanol with a weight percentage of 100 37g of concentrated phosphoric acid in a high-speed shear homogenizer was stirred and mixed evenly, and kept at 70°C, and then this part of the mixture of isobutanol and phosphoric acid was added to the reactor at a constant speed for 7 hours. Dissolution coprecipitation reaction, keeping the reaction temperature at 105°C, and continuing the reaction for 16 hours to obtain a blue paste-colored suspension of the vanadium phosphorus oxygen catalyst precursor, the reaction product was vacuum filtered and dried after cooling down to room temperature. The filter cake in the suction filtration process was washed three times with isobutanol, the filter cake was naturally air-dried at room temperature, then placed in an oven, dried at 120°C...

Embodiment 2

[0035] Using a four-necked flask with a stirring and reflux cooling device, add 45g of isobutanol and 5.0g of vanadium pentoxide into the four-necked flask, add 0.06g of ferric sulfate as an additive, start stirring, and heat up to 90°C; 52g of isobutanol Butanol and 5.5g of concentrated phosphoric acid with a weight percentage of 110% were stirred and mixed evenly in a high-speed shear homogenizer, and kept at 70°C, and then this part of the mixture of isobutanol and phosphoric acid was controlled for 4 hours. Add a uniform flow into the reactor for dissolution and co-precipitation reaction, keep the reaction temperature at 100°C, and continue the reaction for 8 hours to obtain a blue paste-colored suspension of the vanadium phosphorus oxide catalyst precursor. The reaction product is reduced to room temperature and vacuum pumped Filter and dry. The filter cake in the suction filtration process was washed three times with isobutanol, the filter cake was air-dried naturally at...

Embodiment 3

[0037] Using a four-necked flask with a stirring and reflux cooling device, add 120g of isobutanol and 10.0g of vanadium pentoxide into the four-necked flask, start stirring, and heat up to 100°C; mix 70g of isobutanol with a weight percentage of 115 % concentrated phosphoric acid 12.2g was stirred and mixed evenly in a high-speed shear homogenizer, and kept at 70°C, and then the mixture of isobutanol and phosphoric acid was added to the reactor at a constant speed for 8 hours. Carry out elution co-precipitation reaction, keep the reaction temperature at 105°C, and continue the reaction for 12 hours to obtain a blue paste-colored suspension of the vanadium phosphorus oxide catalyst precursor. After the reaction product is lowered to room temperature, it is vacuum filtered and dried. The filter cake in the suction filtration process was washed three times with isobutanol, and the filter cake was air-dried at room temperature, then placed in an oven, dried at 120°C for 8 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com