Large-size ultra-pure vanadium sputtering target material for integrated circuit chip and preparation process thereof

A sputtering target material and a preparation process technology, which are applied in the field of large-sized ultra-high-purity vanadium sputtering target material and its preparation, and can solve the problem of difficult industrial production, small size of high-purity vanadium target material, and purity that cannot meet the requirements of electronic-grade products, etc. problem, to achieve the effect of consistent grain distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

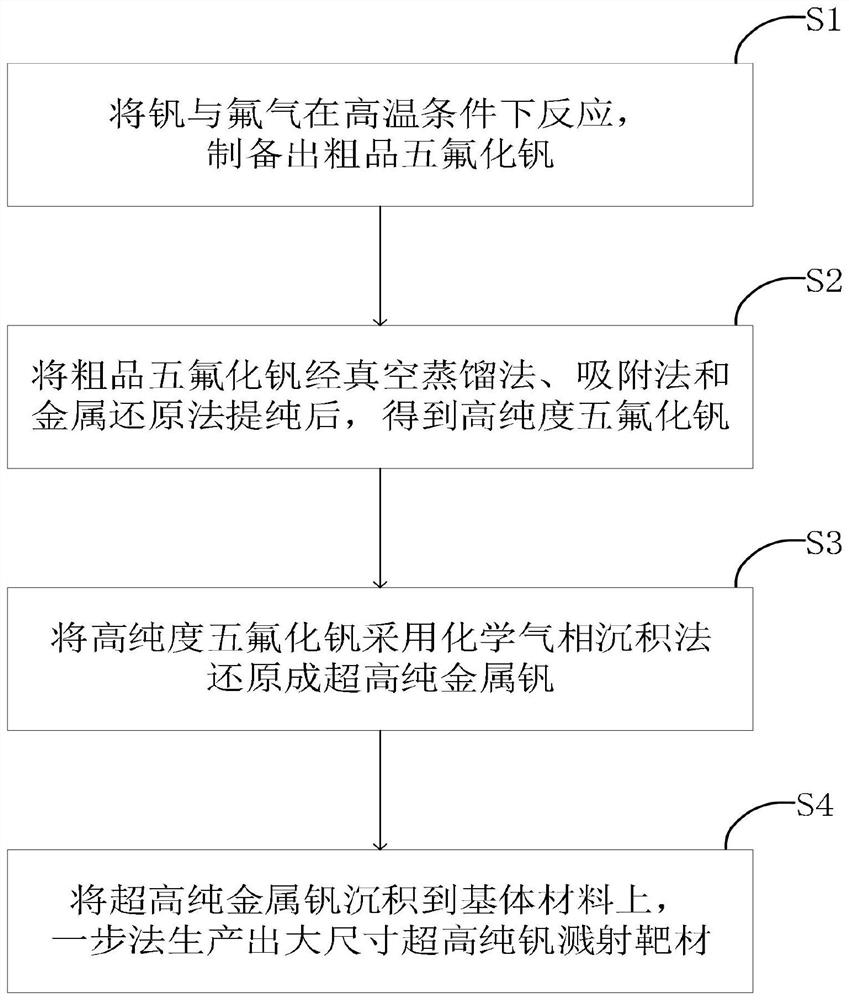

[0046] A method for preparing a large-scale ultra-high-purity vanadium sputtering target for an integrated circuit chip, comprising the following steps:

[0047] Step S1, reacting vanadium and fluorine gas under high temperature conditions to prepare crude vanadium pentafluoride;

[0048] In step S2, the crude vanadium pentafluoride is purified by vacuum distillation, adsorption and metal reduction to obtain high-purity vanadium pentafluoride;

[0049] Step S3, reducing high-purity vanadium pentafluoride into ultra-high-purity metal vanadium by chemical vapor deposition;

[0050] Step S4, depositing ultra-high-purity metal vanadium on the base material, and producing a large-scale ultra-high-purity vanadium sputtering target in one step.

[0051] Wherein, the fluorine gas (diluted with nitrogen gas) in step S1 is fluorine gas (diluted with nitrogen gas) with a purity of 99.999% or more, and the metal vanadium is vanadium powder with a purity of 99.95% or more.

[0052] Speci...

Embodiment 2

[0062] A method for preparing a large-scale ultra-high-purity vanadium sputtering target for an integrated circuit chip, comprising the following steps:

[0063] Step S1, reacting vanadium and fluorine gas under high temperature conditions to prepare crude vanadium pentafluoride;

[0064] In step S2, the crude vanadium pentafluoride is purified by vacuum distillation, adsorption and metal reduction to obtain high-purity vanadium pentafluoride;

[0065] Step S3, reducing high-purity vanadium pentafluoride into ultra-high-purity metal vanadium by chemical vapor deposition;

[0066] Step S4, depositing ultra-high-purity metal vanadium on the base material, and producing a large-scale ultra-high-purity vanadium sputtering target in one step.

[0067] Wherein, the fluorine gas (diluted with nitrogen gas) in step S1 is fluorine gas (diluted with nitrogen gas) with a purity of 99.999% or more, and the metal vanadium is vanadium powder with a purity of 99.95% or more.

[0068] Speci...

Embodiment 3

[0078] A method for preparing a large-scale ultra-high-purity vanadium sputtering target for an integrated circuit chip, comprising the following steps:

[0079] Step S1, reacting vanadium and fluorine gas under high temperature conditions to prepare crude vanadium pentafluoride;

[0080] In step S2, the crude vanadium pentafluoride is purified by vacuum distillation, adsorption and metal reduction to obtain high-purity vanadium pentafluoride;

[0081] Step S3, reducing high-purity vanadium pentafluoride into ultra-high-purity metal vanadium by chemical vapor deposition;

[0082] Step S4, depositing ultra-high-purity metal vanadium on the base material, and producing a large-scale ultra-high-purity vanadium sputtering target in one step.

[0083] Wherein, the fluorine gas (diluted with nitrogen gas) in step S1 is fluorine gas (diluted with nitrogen gas) with a purity of 99.999% or more, and the metal vanadium is vanadium powder with a purity of 99.95% or more.

[0084] Speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com