Construction method for enhancing strength of cement mixing pile through combination of fiber reinforcement and electroosmosis method

A technology of cement mixing pile and fiber reinforcement, which is applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problem of delaying the construction progress of the superstructure, resistance to horizontal load of foundation pile, low impact load capacity of uplift load, low impact load capacity of cement and soil, etc. The problem of long hardening time, etc., can achieve the effect of increasing the current size and soil conductivity, enhancing the unconfined compressive strength, and optimizing the electroosmotic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A construction method for strengthening the strength of cement mixing piles with fiber reinforcement combined with electroosmosis method. In order to improve the strength of cement soil and accelerate the hardening speed of cement soil, polypropylene fibers are mixed into the mixture and steel bars are inserted during construction with the help of electroosmosis method. Accelerate pile precipitation.

[0027] The construction method of fiber reinforcement combined with electroosmotic method to enhance the strength of cement mixing pile in this embodiment includes the following construction steps:

[0028] a. Before construction, the construction site of the mixing pile should be leveled in advance, and all obstacles on the ground and underground at the pile position should be removed. When the site is low-lying, clay should be backfilled, and miscellaneous soil should not be backfilled;

[0029] b. Carry out measurement and setting out according to the pile position des...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, especially in that:

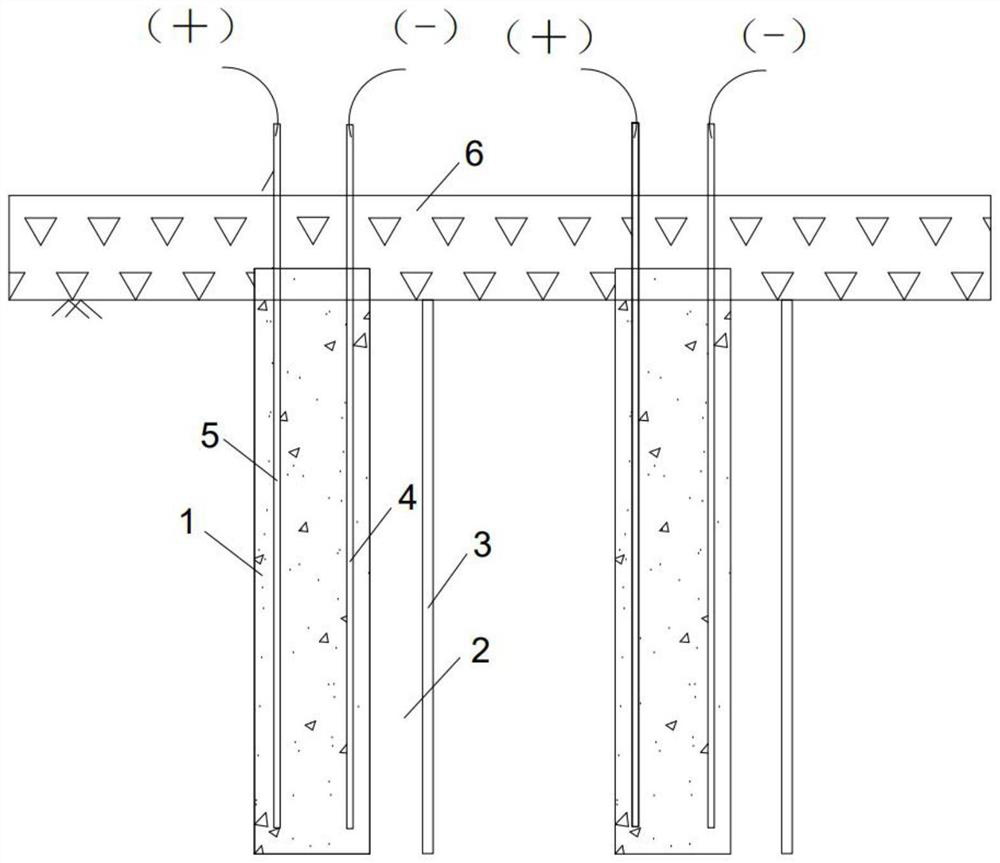

[0039] Such as figure 1 as shown, figure 1 It is a schematic diagram of the operation of strengthening the strength of cement mixing piles by combining fiber reinforcement and electroosmotic method in the present invention.

[0040] The embodiment of the present invention provides a construction method for strengthening the strength of cement mixing piles with fiber reinforcement combined with electroosmotic method, which includes: adding calcium chloride as an admixture to the ordinary Portland cement mixture, and mixing it with polypropylene fiber combine. After the pile position is drilled to the design depth, the drill bit of the powder spraying pile machine is stirred and lifted, and the reinforced mixture is fully stirred into the soil through the nozzle at the end of the drill pipe in the powder spraying system. Insert steel bars on both sides of the fiber-reinforced cement mixing pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com