Organic waterproof emulsion coating and preparation method thereof

A technology for waterproof emulsions and coatings, which is applied in mixing methods, chemical instruments and methods, mixers with rotary stirring devices, etc., to achieve the effects of wide applicability, good tensile properties and adhesion, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

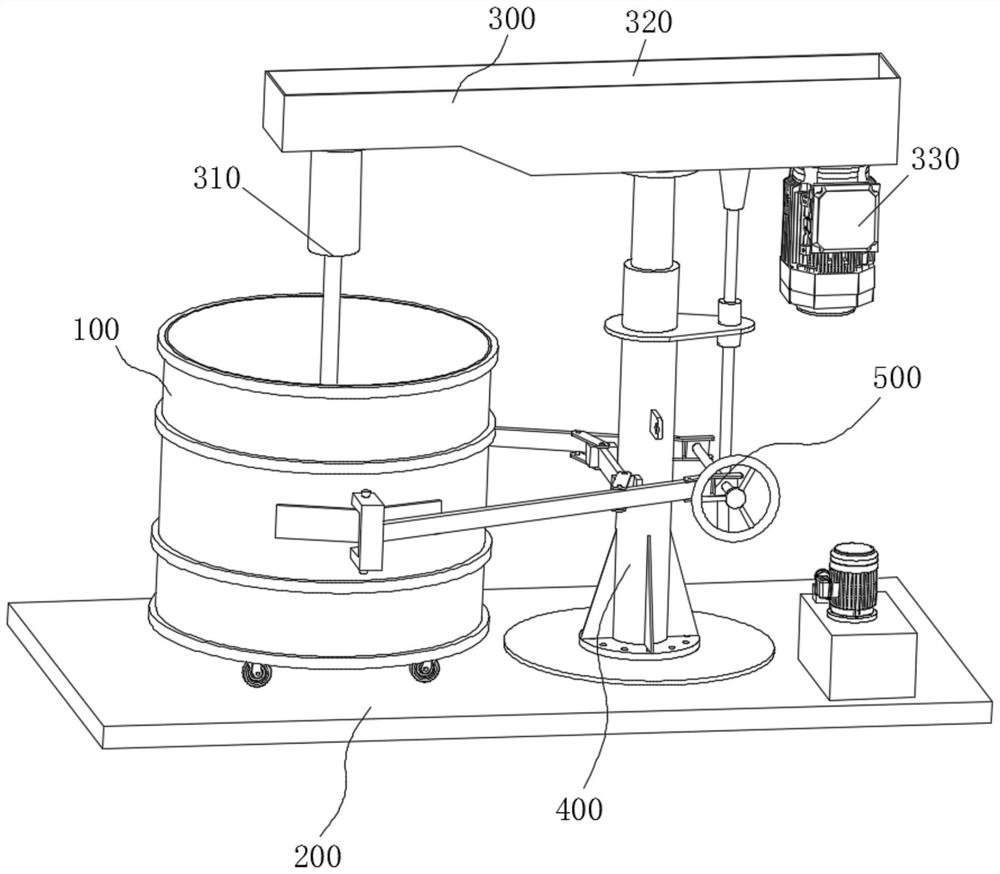

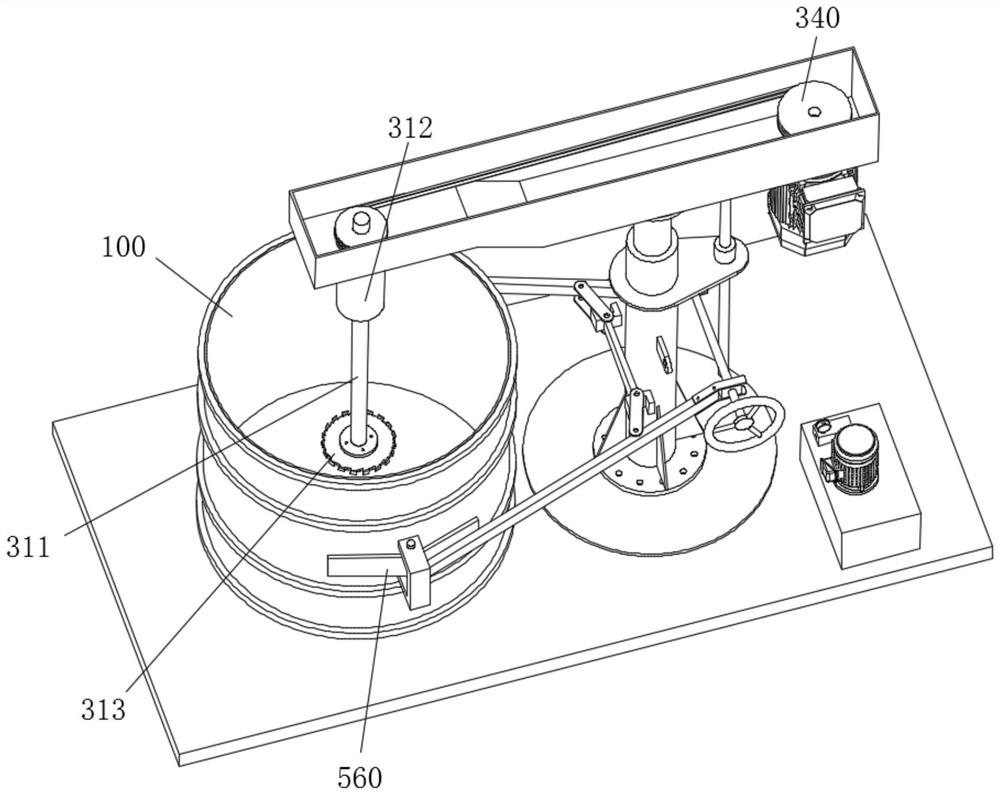

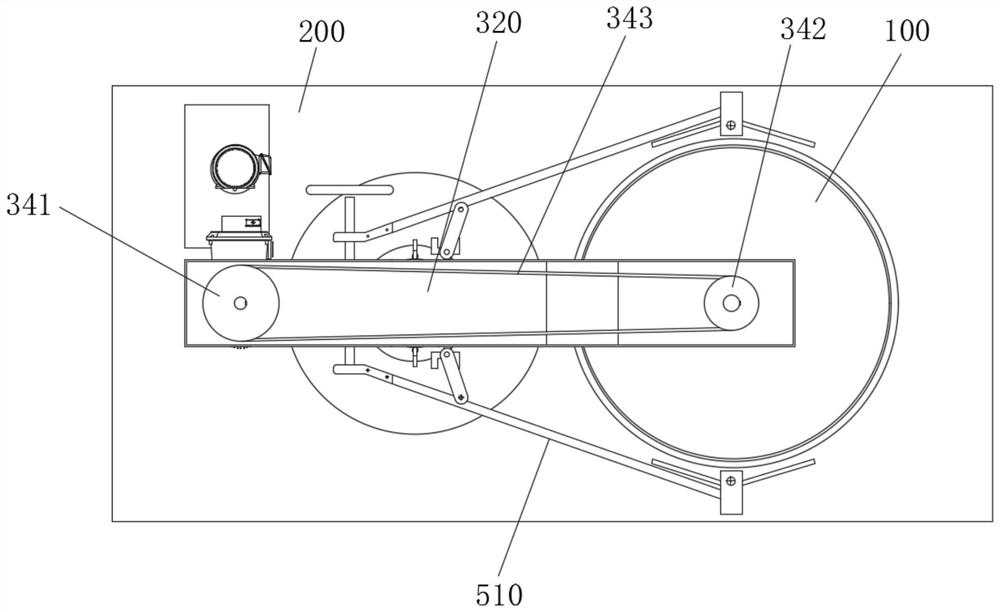

Image

Examples

Embodiment 1

[0030] An organic waterproof emulsion paint, comprising the following raw materials in parts by weight: 70 parts of emulsion, 3.5 parts of waterproofing agent, 15 parts of filler, 5 parts of stabilizer, 3.5 parts of plasticizer, 0.35 part of defoamer, 0.2 part of preservative, dispersant 0.3 parts, 7.5 parts of curing agent.

[0031] The emulsion is composed of acrylate elastic waterproof emulsion, cement-specific high-elastic waterproof emulsion and polyurethane modified acrylate emulsion; the filler is one or more of titanium dioxide, talc powder, wollastonite powder, heavy calcium, quartz powder, mica powder, and sodium bentonite Several kinds; the curing agent is composed of water and silicate solution; the stabilizer is ultrafine aluminum silicate; the plasticizer is dibutyl phthalate or dioctyl phthalate; the dispersant is water-based dispersant; The plasticizer is hydroxyethyl cellulose.

Embodiment 2

[0033] An organic waterproof emulsion paint, comprising the following raw materials in parts by weight: 60 parts of emulsion, 2 parts of waterproofing agent, 10 parts of filler, 3 parts of stabilizer, 2 parts of plasticizer, 0.2 part of defoamer, 0.1 part of preservative, dispersant 0.1 parts, 5 parts of curing agent.

[0034] The emulsion is composed of acrylate elastic waterproof emulsion, cement-specific high-elastic waterproof emulsion and polyurethane modified acrylate emulsion; the filler is one or more of titanium dioxide, talc powder, wollastonite powder, heavy calcium, quartz powder, mica powder, and sodium bentonite Several kinds; the curing agent is composed of water and silicate solution; the stabilizer is ultrafine aluminum silicate; the plasticizer is dibutyl phthalate or dioctyl phthalate; the dispersant is water-based dispersant; The plasticizer is hydroxyethyl cellulose.

Embodiment 3

[0036] An organic waterproof emulsion paint, comprising the following raw materials in parts by weight: 80 parts of emulsion, 5 parts of waterproofing agent, 20 parts of filler, 7 parts of stabilizer, 5 parts of plasticizer, 0.5 part of defoamer, 0.3 part of preservative, dispersant 0.5 parts, curing agent 10 parts

[0037] The emulsion is composed of acrylate elastic waterproof emulsion, cement-specific high-elastic waterproof emulsion and polyurethane modified acrylate emulsion; the filler is one or more of titanium dioxide, talc powder, wollastonite powder, heavy calcium, quartz powder, mica powder, and sodium bentonite Several kinds; the curing agent is composed of water and silicate solution; the stabilizer is ultrafine aluminum silicate; the plasticizer is dibutyl phthalate or dioctyl phthalate; the dispersant is water-based dispersant; The plasticizer is hydroxyethyl cellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com