Epoxy resin composition as well as preparation method and application thereof

A technology of epoxy resin and composition, which is applied in the direction of epoxy resin glue, epoxy polymerized polyolefin adhesive, aldehyde/ketone condensation polymer adhesive, etc., which can solve the problems of low bonding strength and packaging bonding Poor properties and other problems, to achieve the effect of enhanced bonding, good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] According to a preferred embodiment of the present invention, the preparation method further includes: cooling and pulverizing the melt-kneaded epoxy resin composition to obtain the epoxy resin composition.

[0051] Preferably, the particle size of the pulverized epoxy resin composition does not exceed 1.5 mm.

[0052] The third aspect of the present invention provides the application of the above epoxy resin composition in the copper-nickel-plated frame package;

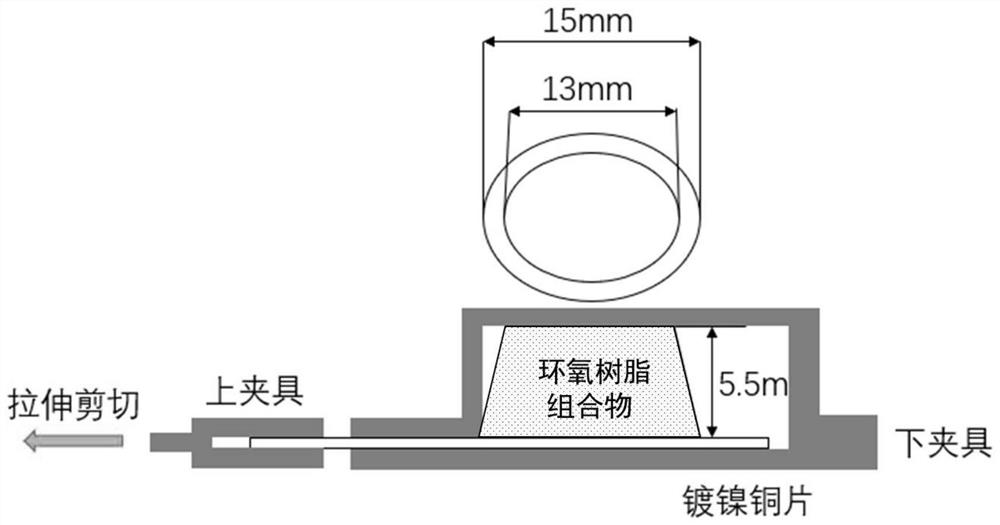

[0053] Wherein, the application includes molding the epoxy resin composition on a nickel-plated copper frame.

[0054] In the present invention, the epoxy resin composition has excellent adhesion performance on the metal frame, especially for copper-nickel-plated frame packaging with higher reliability, and can avoid defects such as delamination caused by insufficient adhesion .

[0055] According to the present invention, the molding conditions have a wide range and can be adjusted according to actual appl...

Embodiment 1-13

[0084]After weighing and mixing according to the proportion of each component in Table 1, melt and knead uniformly on an open mill preheated at a temperature of 65-95 ℃, and then remove the uniformly mixed material from the mill and naturally cool it, and pulverize to obtain powder. After passing through a 10-mesh sieve, the particle size of the powdery material after sieving does not exceed 1.5mm. Further preformed to obtain the cake of epoxy resin composition, the density of preformed cake is 1.6-2.1g / cm 3 , evaluated by the following methods, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com