Processing method for refining Ti-V alloy grains

A processing method and alloy technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of recrystallized grain growth, affecting performance, and not being deeply explored, so as to eliminate shrinkage cavities and improve Effect of number and total area of grain boundaries, enhanced activation performance and reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

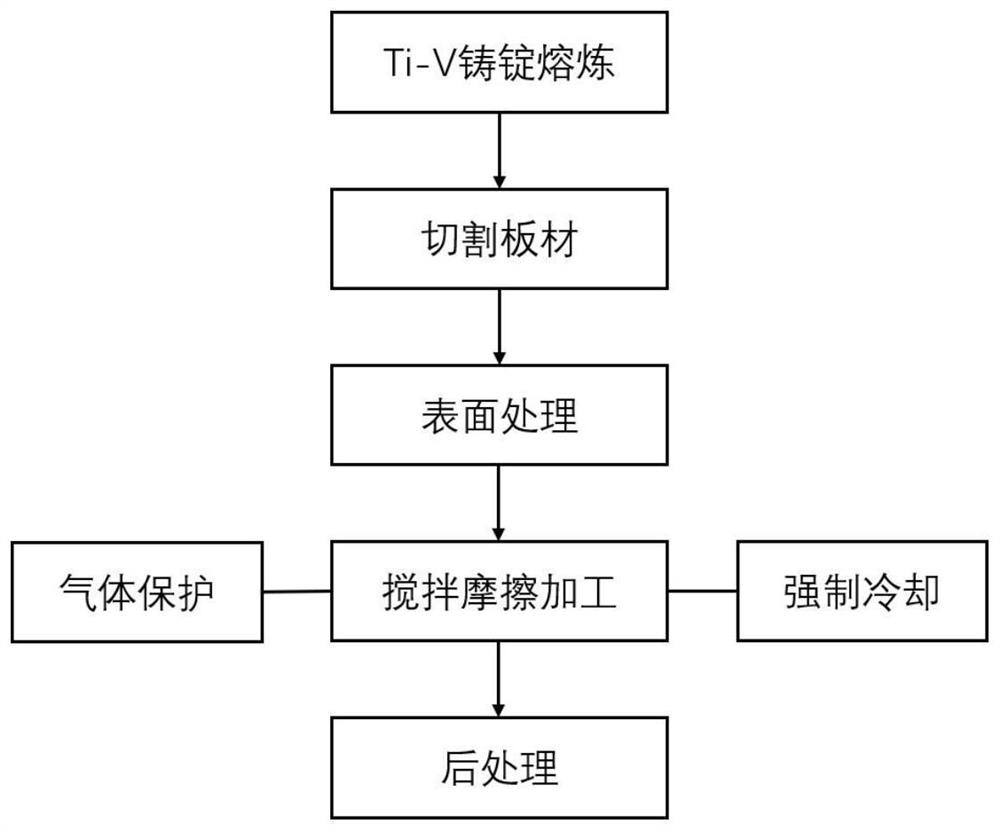

[0029] A processing method for refining Ti-V alloy grains, comprising the following specific steps:

[0030] (1) Smelting: Using sponge titanium and dendritic vanadium as raw materials, the above raw materials are smelted into Ti-V alloy ingots by vacuum consumable arc melting; and the purity of the sponge titanium and dendritic vanadium is not less than 99.9% %; Gained Ti-V alloy ingot is the solid solution alloy of BCC structure; The chemical composition general formula of described Ti-V alloy ingot is expressed as Ti 0.9 V 0.1 ;

[0031] (2) Cutting: the obtained Ti-V alloy ingot (Ti 0.9 V 0.1 ) cut into a Ti-V alloy plate with a thickness of 2mm;

[0032] (3) surface treatment: the surface of the obtained Ti-V alloy plate is polished and cleaned;

[0033] (4) Friction stir processing: under the protection of an inert gas (argon gas), carry out single-pass friction stir processing to the above-mentioned surface-treated Ti-V alloy plate to prevent oxidation; wherein: th...

Embodiment 2

[0038] A processing method for refining Ti-V alloy grains, comprising the following specific steps:

[0039] (1) Smelting: Using sponge titanium and dendritic vanadium as raw materials, the above raw materials are smelted into Ti-V alloy ingots by vacuum consumable arc melting; and the purity of the sponge titanium and dendritic vanadium is not less than 99.9% %; Gained Ti-V alloy ingot is the solid solution alloy of BCC structure; The chemical composition general formula of described Ti-V alloy ingot is expressed as Ti0.5 V 0.5 ;

[0040] (2) Cutting: the obtained Ti-V alloy ingot (Ti 0.5 V 0.5 ) cut into a Ti-V alloy plate with a thickness of 3mm;

[0041] (3) surface treatment: the surface of the obtained Ti-V alloy plate is polished and cleaned;

[0042] (4) Friction stir processing: under the protection of an inert gas (argon gas), carry out single-pass friction stir processing to the above-mentioned surface-treated Ti-V alloy plate to prevent oxidation; wherein: the ...

Embodiment 3

[0047] A processing method for refining Ti-V alloy grains, comprising the following specific steps:

[0048] (1) Smelting: Using sponge titanium and dendritic vanadium as raw materials, the above raw materials are smelted into Ti-V alloy ingots by vacuum consumable arc melting; and the purity of the sponge titanium and dendritic vanadium is not less than 99.9% %; Gained Ti-V alloy ingot is the solid solution alloy of BCC structure; The chemical composition general formula of described Ti-V alloy ingot is expressed as Ti 0.7 V 0.3 ;

[0049] (2) Cutting: the obtained Ti-V alloy ingot (Ti 0.7 V 0.3 ) cut into a Ti-V alloy plate with a thickness of 2mm;

[0050] (3) surface treatment: the surface of the obtained Ti-V alloy plate is polished and cleaned;

[0051] (4) Friction stir processing: under the protection of an inert gas (argon gas), carry out single-pass friction stir processing to the above-mentioned surface-treated Ti-V alloy plate to prevent oxidation; wherein: th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com