Preparation method of ZIF-8-loaded Janus electrospun fibrous membrane

A ZIF-8, electrospinning fiber technology, used in fiber processing, electrospinning, fiber chemical characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention at first provides a kind of preparation method of the Janus electrospun fiber membrane of loading ZIF-8, and this method comprises:

[0029] Step 1: After dissolving PVP in the solvent and stirring overnight, mix ZIF-8 with the PVP solution;

[0030] Step 2: Dissolve PCL in the mixed solvent and stir overnight;

[0031] Step 3: Mix the PVP solution containing ZIF-8 and the PCL solution in equal volumes, and after phase separation occurs, prepare a Janus electrospun fiber membrane loaded with ZIF-8 by uniaxial electrospinning technology.

[0032] According to the present invention, PVP is first dissolved in N-N dimethylformamide, PCL is dissolved in chloroform and N-N dimethylformamide (4:1) mixed solution, the concentration of said PVP is preferably 14wt%, The concentration of PCL is preferably 14wt%, and then ZIF-8 is dissolved in the PVP solution, the concentration of ZIF-8 is preferably 14wt%, and an equal volume of PCL solution is mixed with t...

Embodiment 1

[0035] The preparation of embodiment 1PP JNF

[0036] PVP is dissolved in N-N dimethylformamide, PCL is dissolved in chloroform and N-N dimethylformamide (4:1) mixed solution, the concentration of PVP is preferably 14wt%, the concentration of described PCL is preferably 14wt%, and then mix equal volumes of PVP and PCL solutions, and after phase separation occurs in the solution, uniaxial electrospinning technology is used, the applied voltage is 13-15kV, the receiving distance is 18cm, and the flow rate is 1mL / h to prepare PP JNF.

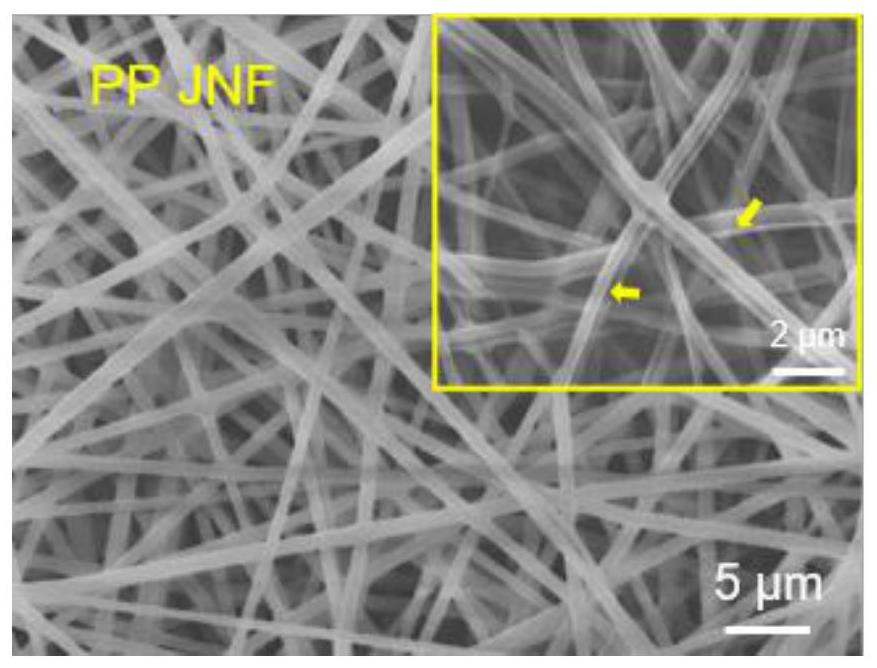

[0037] The PP JNF obtained in Example 1 was observed using a scanning electron microscope to observe the morphology of the sample, figure 1 The microstructure of PPJNF is shown. The diameter of PP JNF fibers is uniform, with an average diameter of 797±138nm. After dissolving in water, the groove structure of the fibers can be observed, which is caused by the dissolution of PVP.

Embodiment 2

[0038] The preparation of embodiment 2PPZ JNF

[0039] PVP is dissolved in N-N dimethylformamide, PCL is dissolved in chloroform and N-N dimethylformamide (4:1) mixed solution, the concentration of described PVP is preferably 14wt%, the concentration of PCL is preferably 14wt%, and then ZIF-8 is dissolved in the PVP solution, and the concentration of ZIF-8 is preferably 14wt%, and an equal volume of PCL solution is mixed with the PVP solution loaded with ZIF-8, and after phase separation occurs in the solution, a single Shaft electrospinning technology, the applied voltage is 13-15kV, the receiving distance is 18cm, and the flow rate is 1mL / h to prepare PPZ JNF.

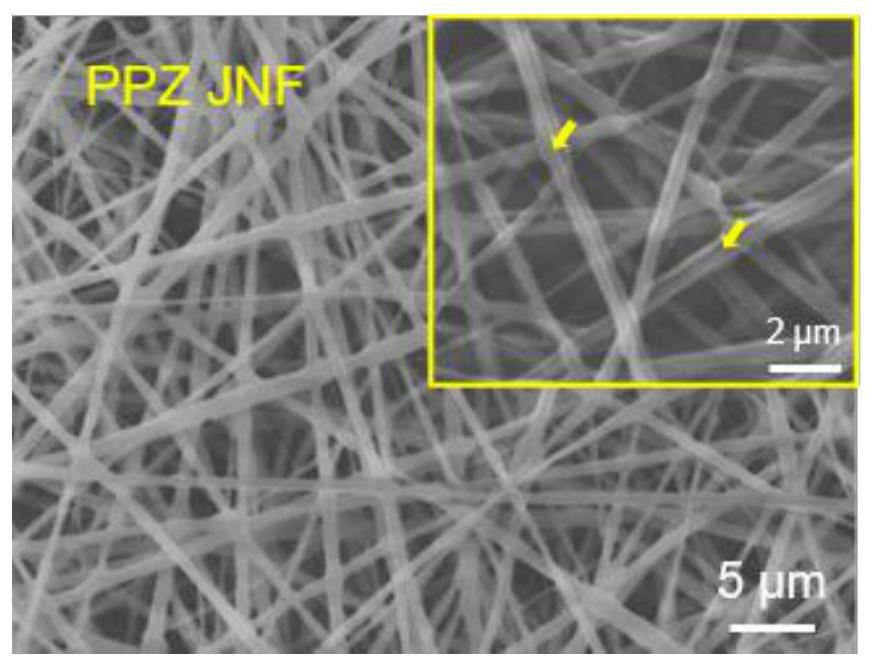

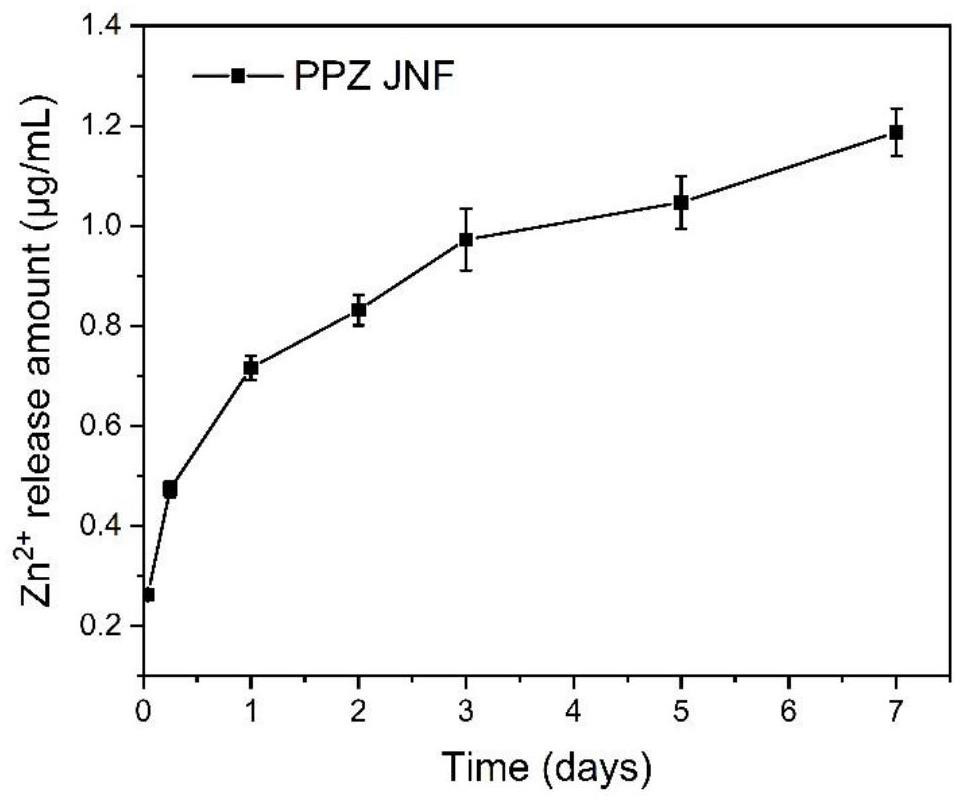

[0040] The PPZ JNF obtained in Example 2 was observed using a scanning electron microscope to observe the morphology of the sample, figure 2 It shows the microstructure of PPZ JNF. The fiber diameter of PPZ JNF is not uniform, and the swelling part can be seen, which is caused by the incorporation of ZIF-8. After d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com