Gold plating process for three-dimensional glazed ceramic tile

A process and three-dimensional technology, which is applied in the gold-plating process of three-dimensional polished glazed tiles, can solve the problems of poor three-dimensional effect, poor bonding performance, and falling off of the gold-plated layer, and achieve the effect of improving aesthetics, good compatibility, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

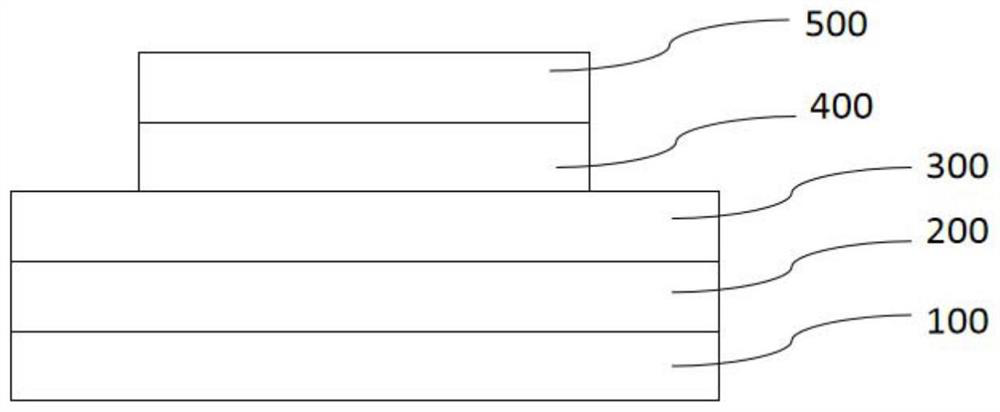

[0035] Embodiment 1: Gold-plating process of three-dimensional polished glazed ceramic tile

[0036] A gold-plating process for three-dimensional glazed tiles, comprising the following steps:

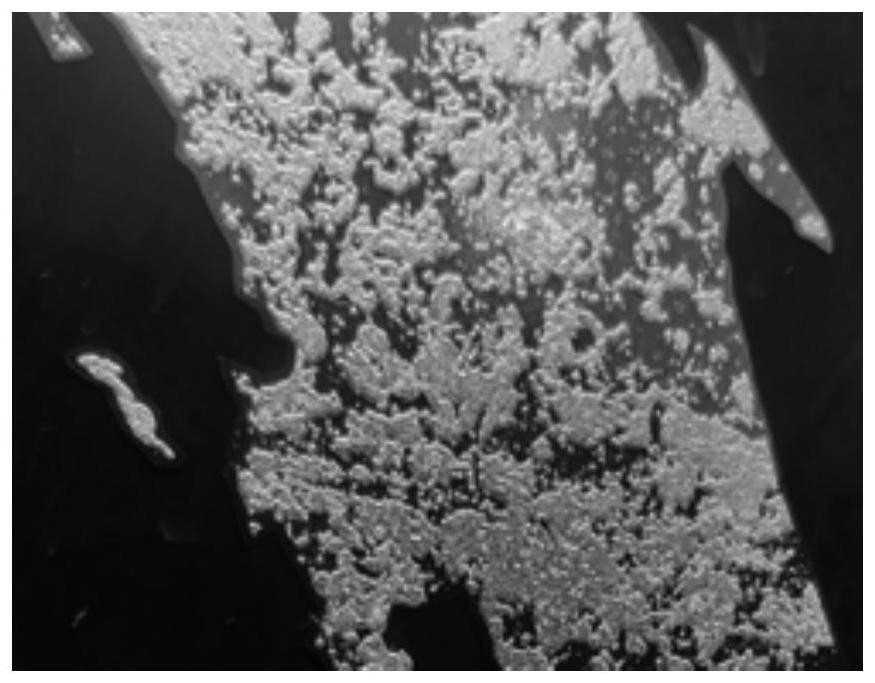

[0037] Wipe the surface of the adobe clean, then make a pattern layer by decal technique, then spread frit powder on the pattern layer, and go through the first sintering (the temperature of the first sintering is 800°C, and the time of the first sintering is 3 hours ) to form a transparent layer, the transparent layer is polished and cleaned (cleaning is to use ultrasonic waves to clean, the operating current of the equipment that sends out the ultrasonic waves is 5 amperes, and the cleaning time is 40 minutes), and then the convex glaze is applied on the surface of the transparent layer, and then Carry out the second sintering (the temperature of the second sintering is 650 ℃, the time of the second sintering is 3 hours), after the second sintering, the convex glaze material forms a c...

Embodiment 2

[0041] Embodiment 2: Gold-plating process of three-dimensional glazed tiles

[0042] A gold-plating process for three-dimensional glazed tiles, comprising the following steps:

[0043] Wipe the surface of the adobe clean, then make a pattern layer by decal technique, then spread frit powder on the pattern layer, and go through the first sintering (the temperature of the first sintering is 900°C, and the time of the first sintering is 2 hours ) to form a transparent layer, the transparent layer is polished and cleaned (cleaning is to use ultrasonic waves to clean, the operating current of the equipment that sends out the ultrasonic waves is 5 amperes, and the cleaning time is 40 minutes), and then the convex glaze is applied on the surface of the transparent layer, and then Carry out the second sintering (the temperature of the second sintering is 640°C, and the time of the second sintering is 4 hours). After the second sintering, the convex glaze material forms a convex glaze ...

Embodiment 3

[0046] Embodiment 3: Gold-plating process of three-dimensional polished glazed ceramic tile

[0047] A gold-plating process for three-dimensional glazed tiles, comprising the following steps:

[0048] Wipe the surface of the adobe clean, then make a pattern layer by screen printing, then spread frit powder on the pattern layer, and go through the first sintering (the temperature of the first sintering is 1000°C, the time of the first sintering 1 hour) to form a transparent layer, and the transparent layer is polished and cleaned (cleaning is performed by ultrasonic waves, the operating current of the ultrasonic equipment is 5 amperes, and the cleaning time is 40 minutes), and then the convex glaze is applied on the surface of the transparent layer material, and then carry out the second sintering (the temperature of the second sintering is 630°C, and the time of the second sintering is 2 hours). After the second sintering, the convex glaze material forms a convex glaze layer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com