Polycarboxylate concrete water reducer and preparation method thereof

A concrete water-reducing agent, polycarboxylate-based technology, applied in the field of polycarboxylate-based concrete water-reducing agent and its preparation, can solve the problem of harsh reaction conditions, unimproved chloride ion penetration resistance, and unremarkable improvement in compressive performance and other problems, to achieve the effect of improving the adsorption force, improving the toughening effect, and improving the effect of water reduction and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

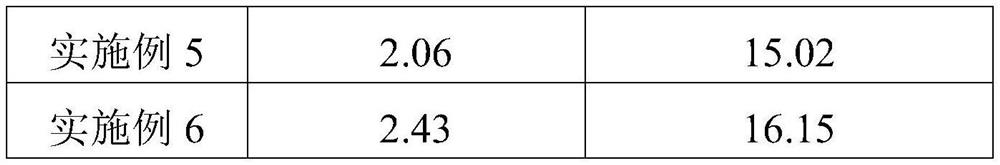

Examples

Embodiment 1

[0034] The preparation method of polycarboxylate concrete water reducing agent comprises the following steps:

[0035] (1) Add 100 parts by weight of EPEG to 400 parts by weight of water and mix uniformly to obtain an aqueous solution of EPEG; add 0.1 parts by weight of sodium methacrylate and 0.2 parts by weight of ascorbic acid to 30 parts by weight of water and mix uniformly to obtain a mixed solution I; Parts by weight of acrylic acid, 1.6 parts by weight of 25 wt% hydrogen peroxide, and 0.1 parts by weight of mercaptoacetic acid were added to 65 parts by weight of water and mixed uniformly to obtain a mixed solution II;

[0036] (2) Add 5 parts by weight of 4-hydroxybutyl vinyl polyoxyethylene ether into the EPEG aqueous solution and react at 25°C for 20min, then add the above mixed solution I and mixed solution II, keep the reaction at 25°C for 5h, and then add 30wt% hydrogen The pH of the sodium oxide aqueous solution was adjusted to 7 to obtain a polycarboxylate concre...

Embodiment 2

[0038] The preparation method of polycarboxylate concrete water reducing agent comprises the following steps:

[0039] (1) Add 2 parts by weight of itaconic acid, 5 parts by weight of 4-hydroxybutyl vinyl polyoxyethylene ether, and 0.01 part by weight of phenothiazine into 300 parts by weight of toluene and mix evenly, then add 0.21 parts by weight of 98 wt% concentrated Sulfuric acid, heated to 100 ° C for 6 hours, rotary evaporation to remove toluene, washed and dried to obtain the intermediate product;

[0040] (2) Add 100 parts by weight of EPEG to 400 parts by weight of water and mix uniformly to obtain an EPEG aqueous solution; add 0.1 parts by weight of sodium methacrylate and 0.2 parts by weight of ascorbic acid to 30 parts by weight of water and mix uniformly to obtain a mixed solution I; Parts by weight of acrylic acid, 1.6 parts by weight of 25 wt% hydrogen peroxide, and 0.1 parts by weight of mercaptoacetic acid were added to 65 parts by weight of water and mixed u...

Embodiment 3

[0043] The preparation method of polycarboxylate concrete water reducing agent comprises the following steps:

[0044] (1) Add 2 parts by weight of itaconic acid, 5 parts by weight of 4-hydroxybutyl vinyl polyoxyethylene ether, and 0.01 part by weight of phenothiazine into 300 parts by weight of toluene and mix evenly, then add 0.21 parts by weight of 98 wt% concentrated Sulfuric acid, heated to 100 ° C for 6 hours, rotary evaporation to remove toluene, washed and dried to obtain the intermediate product;

[0045] (2) Add 100 parts by weight of EPEG to 400 parts by weight of water and mix uniformly to obtain an EPEG aqueous solution; add 0.1 parts by weight of sodium methacrylate and 0.2 parts by weight of ascorbic acid to 30 parts by weight of water and mix uniformly to obtain a mixed solution I; Parts by weight of itaconic acid modified inorganic material, 3 parts by weight of acrylic acid, 1.6 parts by weight of 25 wt% hydrogen peroxide, and 0.1 part by weight of mercaptoac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap