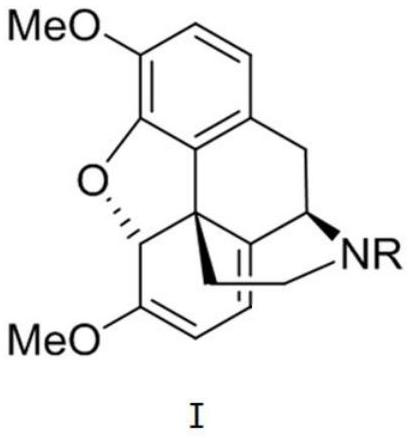

Novel intermediate as well as preparation method and application thereof

An intermediate and reaction technology, applied in the field of novel intermediates and their preparation, can solve the problems of complicated procedures, reduced reaction steps, complicated production processes, etc., and achieves high chemical and optical yields, high reactivity, and high reaction yields. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

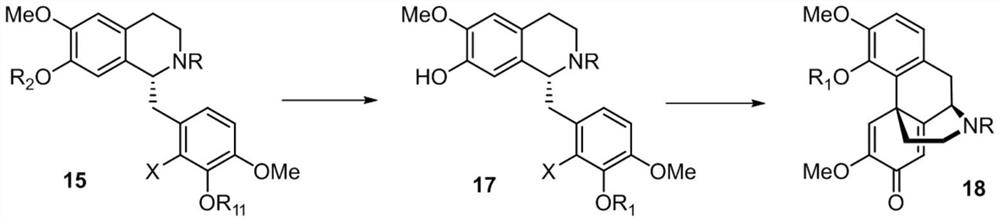

Method used

Image

Examples

Embodiment 1

[0301] The preparation method of embodiment 1 compound 5, with R 3 For H, X is bromine as an example, synthetic compound 5a;

[0302] Include the following steps:

[0303]

[0304] Isvanillin 1a (150 g, 0.986 mol, 1.0 equiv.) was dissolved in dichloromethane (2500 mL), and cooled to 0° C. in an ice bath. Slowly add dibromohydantoin (155g, 0.542mol, 0.55equiv.) in batches under stirring, then the reaction solution is raised to room temperature for reaction, after TLC detects that the raw material disappears completely (about 4 hours), the reaction solution is cooled to 0°C, add saturated Na 2 S 2 o 3 Quench the reaction with aqueous solution (500mL), stir at 0°C for 1h, wait until the precipitate is completely precipitated, filter, wash the filter cake (500mL×3) with water, collect the resulting off-white solid 2a, dry it in an oven at 90°C for 5 hours, and then vacuum It was dried (50°C) for 6 hours and used directly in the next reaction (193 g, yield 85%).

[0305] P...

Embodiment 2

[0308] The preparation method of embodiment 2 compound 5, with R 3 For Me, X is bromine as an example, synthetic compound 5b;

[0309] Include the following steps:

[0310]

[0311] Ph 3 P + CH 2 OMeCl - (911g, 2.66mol, 3.1equiv.) was dispersed in dry tetrahydrofuran (2500mL), and after cooling to 0°C in an ice bath, t-BuOK (279g, 2.48mol, 2.9equiv.) was slowly added thereto, and the reaction solution became orange-red, Stir vigorously for 45 minutes. Compound 2b (210 g, 0.857 mol, 1.0 equiv.) was slowly added to the suspension in batches, and the reaction was naturally raised from 0°C to 20°C. After the disappearance of the raw material was monitored by TLC (about 1 hour). The reaction solution was cooled down to 0 °C again, and water (1000 mL) was added thereto to quench the reaction. The organic layer was separated, and the aqueous layer was extracted with ethyl acetate (1000 mL×3). The organic layers were combined, dried over anhydrous sodium sulfate, filtered, a...

Embodiment 3

[0314] The preparation of embodiment 3 compound 9I: with R 22 Taking the hydrogen atom as an example, compound 9a is synthesized, and the synthetic route is:

[0315]

[0316] Include the following steps:

[0317] Vanillin 6 (200g, 1.31mol, 1.0equiv.) was dissolved in CH 3 NO 2 (1000mL), ethylenediamine (1.0mL) was added thereto under stirring, and heated to reflux. After the reaction was complete (about 2 hours) as monitored by TLC, the reaction solution was cooled to room temperature, and a large amount of yellow solids were precipitated. Filter, wash the filter cake with methanol / water (v / v=1:1) (200mL×3), absolute ethanol (200mL×2) successively, collect the solid, and dry it under reduced pressure with a water pump to obtain compound 7 (bright yellow fine needles). crystals, 185 g, yield 72%).

[0318] Compound 7 (40.0g, 0.205mol, 1.0equiv.) was dissolved in a THF / EtOH mixed solution (v / v=1:1, 480mL), cooled to 0°C in an ice bath, and NaBH was slowly added in batches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com