Polyethylene resin for secondary battery separator, method for manufacturing same and separator using same

A polyethylene resin and secondary battery technology, applied in the field of polyethylene resin, can solve problems such as difficult to achieve uniform melting of extruders, and achieve the effect of ensuring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Preparation of catalysts for polyethylene polymerization

[0046] A catalyst for polyethylene polymerization according to an embodiment of the present invention is prepared by including the following steps: a first step, wherein a magnesium compound solution is prepared by reacting a magnesium compound, an alcohol, and a hydrocarbon solvent; adding titanium tetrachloride to a magnesium compound solution and reacting to prepare a precursor; and a third step in which a catalyst is prepared by reacting the precursor with titanium tetrachloride and a carbonyl compound.

[0047] The magnesium compound may be a magnesium halide compound, such as magnesium chloride, such as magnesium dichloride (MgCl 2 ).

[0048] The hydrocarbon solvent may be an aliphatic hydrocarbon having 1 to 20 carbon atoms such as pentane, hexane, heptane, octane, decane, and kerosene, or an alicyclic hydrocarbon such as cyclopentane, methylcyclopentane, cyclopentane, Hexane and methylcyclohexane, or...

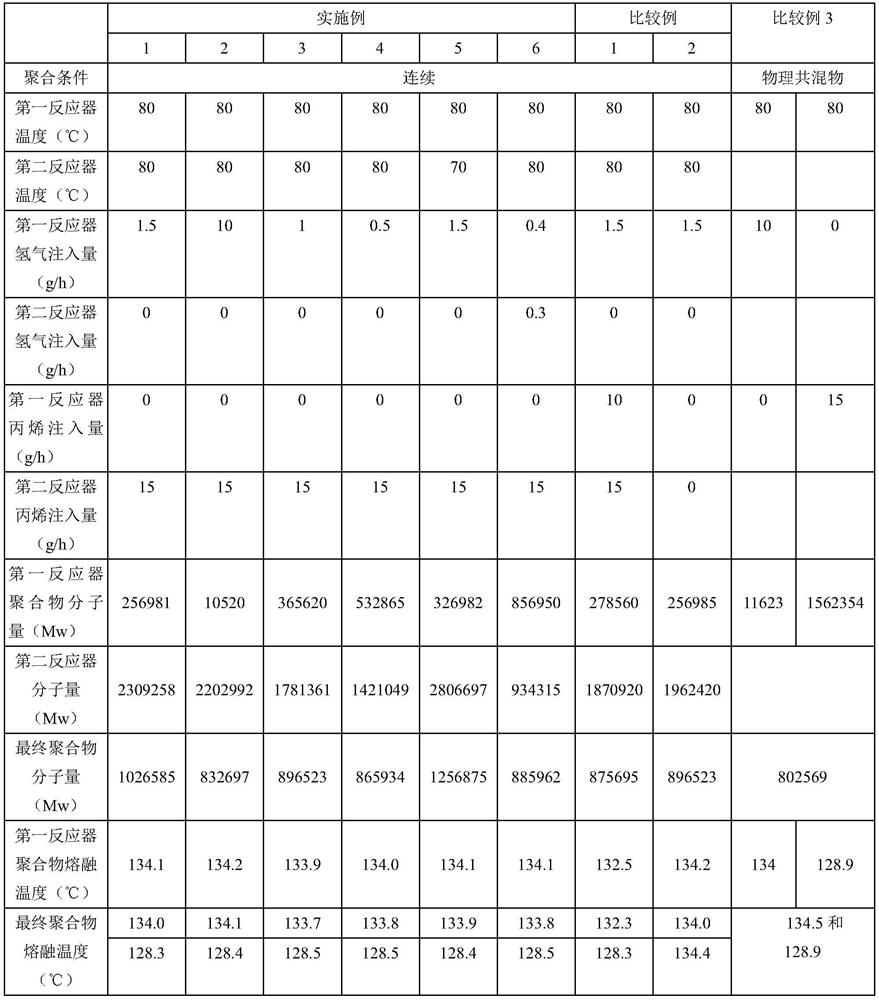

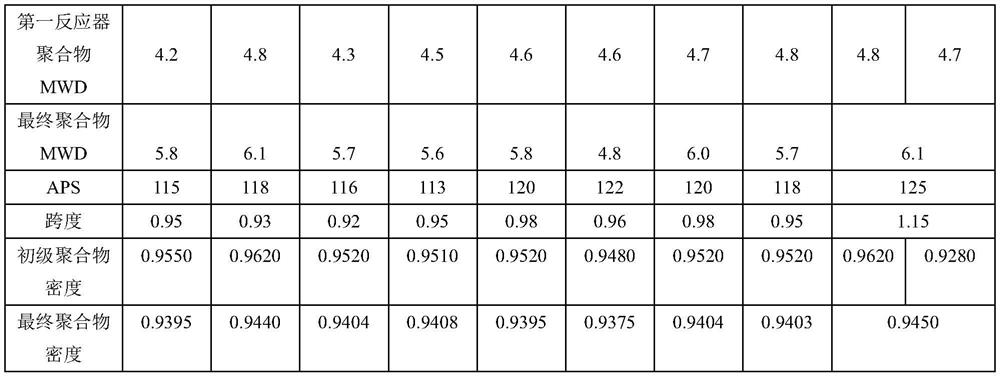

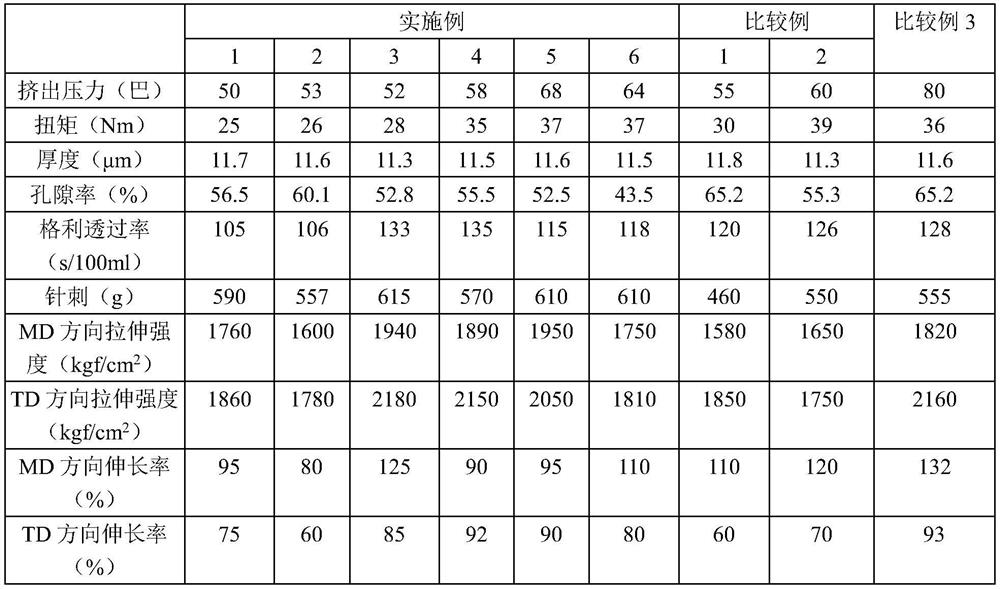

Embodiment 1

[0132] [Preparation of solid catalyst for polyethylene polymerization]

[0133] Step 1: Preparation of Magnesium Halide Compound Solution

[0134] After replacing the 1L-reactor equipped with a mechanical stirrer with a nitrogen atmosphere, 25 g of magnesium dichloride (MgCl 2), 300 ml of toluene and 100 ml of n-butanol, and the temperature was raised to 65° C. for 1 hour while stirring, and then kept for 2 hours, thereby obtaining a uniform magnesium halide compound solution.

[0135] Step 2: Preparation of solid composite titanium catalyst

[0136] After cooling the temperature of the solution prepared in the first step to 40 °C, slowly inject 70 ml of TiCl 4 , for 1 hour. When the injection was complete, the mixture was stirred at 350 rpm, the temperature of the reactor was raised to 60 °C for 1 hour, and aged for an additional 1 hour. When all the processes were completed, the reactor was allowed to stand to completely settle the solid components to remove the supernat...

Embodiment 2

[0153] The catalyst was prepared in the same manner as in Example 1. Polymerization was performed under the same polymerization conditions as in Example 1, except that the amount of hydrogen injected into the first polymerization reactor in Example 1 was changed to 10 g / h. A porous film was formed under the same molding conditions as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| True density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com