Surface-enhanced Raman substrate with both stability and Raman intensity and preparation method of surface-enhanced Raman substrate

A surface-enhanced Raman and high-stability technology, which is applied in Raman scattering, superimposed layer plating, instruments, etc., can solve the problems that limit the practical application of silver-based SERS substrates, poor chemical stability of metallic silver, and low temperature resistance, etc. problems, to achieve excellent three-dimensional conformality, surface-enhanced Raman effect enhancement, and anti-oxidation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a surface-enhanced Raman substrate with high stability and high Raman intensity, comprising the following steps:

[0029] (1) Ultrasonic clean the ITO glass with acetone, isopropanol, ethanol and deionized water for 5 minutes;

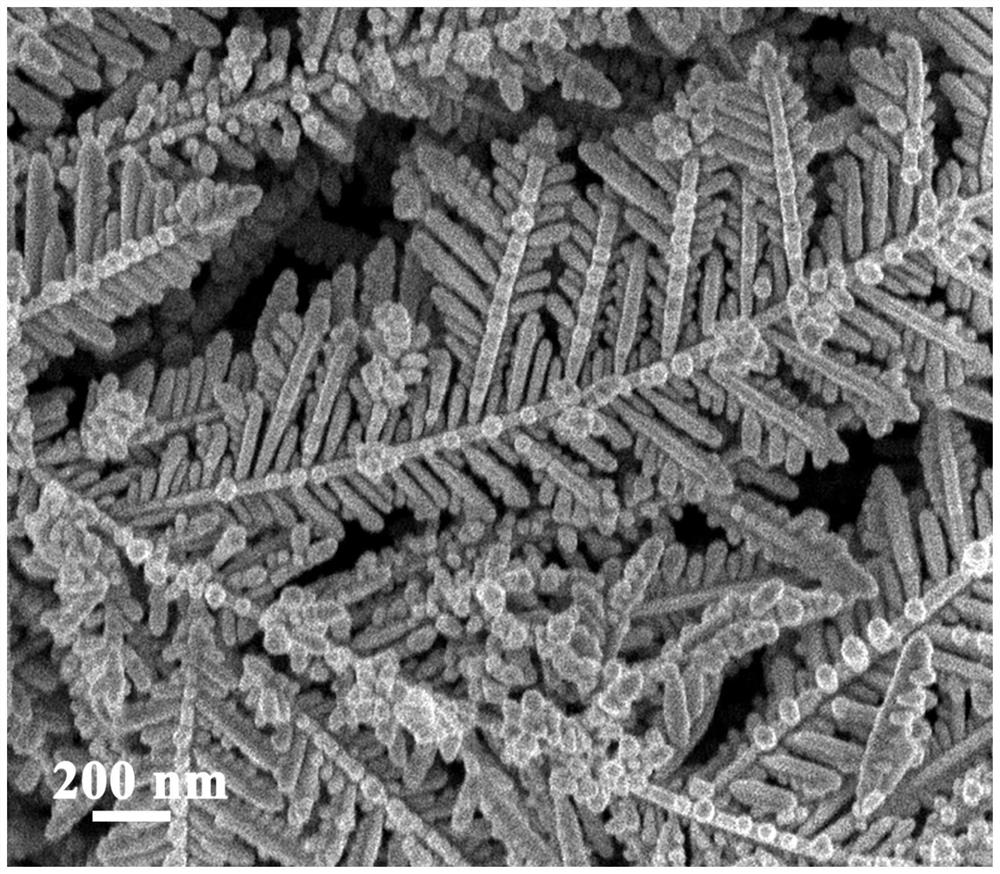

[0030] (2) Use 0.01M silver nitrate and 0.2M citric acid as the electrolyte, and the current density is 2mA / cm 2 , the deposition time is 180s, the metal dendrites are deposited on the substrate obtained above, rinsed with deionized water and dried naturally to obtain the following: figure 1 SEM images of silver dendrites shown;

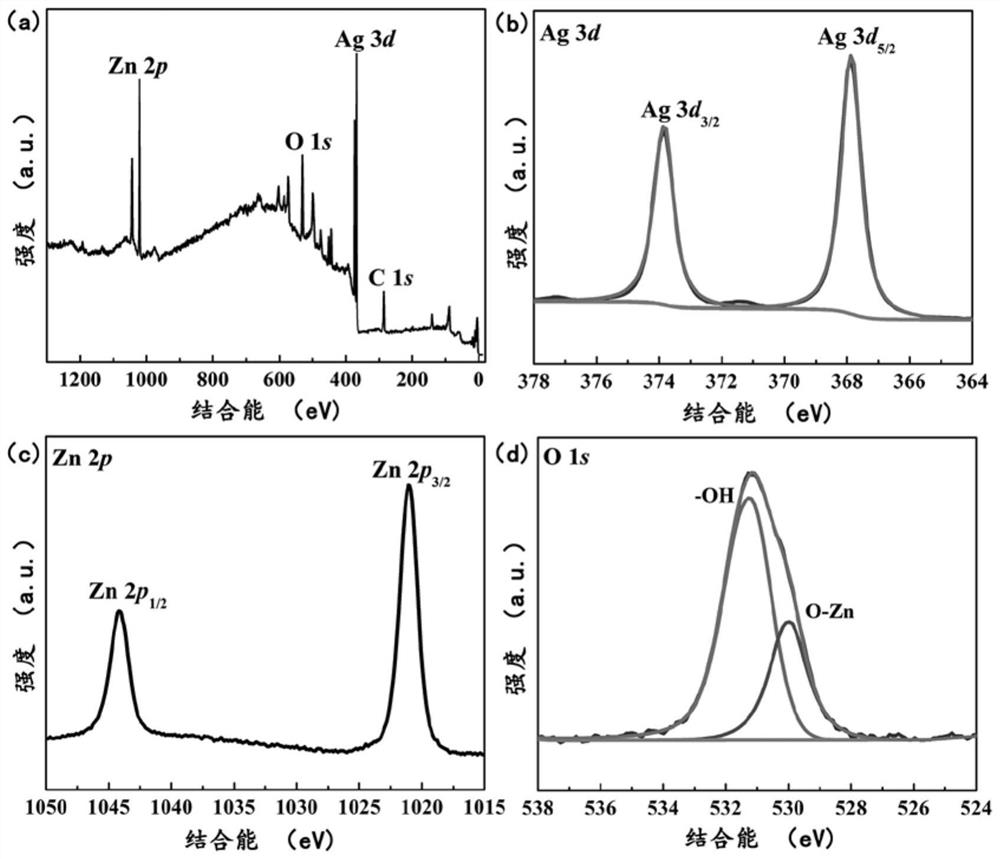

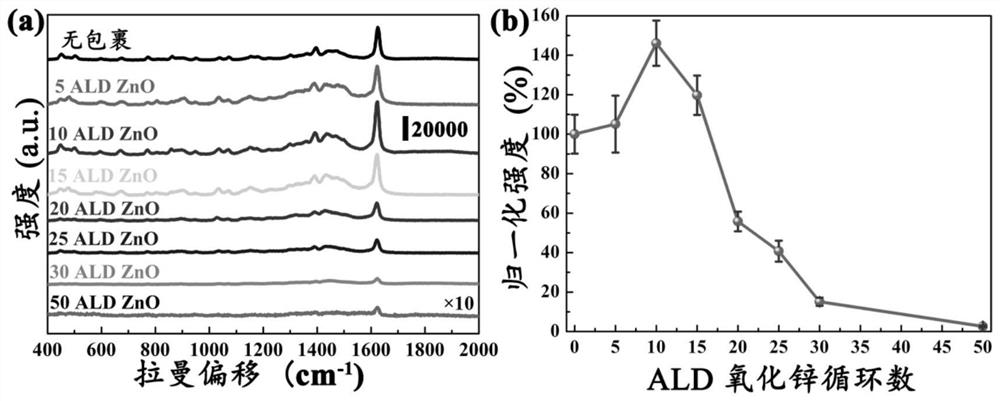

[0031] (3) Transfer the above-mentioned silver dendrite substrate into the ALD reaction chamber, and deposit 5-50 cycles (0.85-8.5 nm) of zinc oxide film to form a zinc oxide-wrapped silver dendrite structure (silver metal dendrite@zinc oxide ), the parameters for ALD deposition of zinc oxide are: reaction chamber temperature: 80 o C, Reaction source: Deposit zinc oxide using diethyl zinc and ...

Embodiment 2

[0035] A method for preparing a surface-enhanced Raman substrate with high stability and high Raman intensity, comprising the following steps:

[0036] (1) Ultrasonic clean the ITO glass with acetone, isopropanol, ethanol and deionized water for 5 minutes;

[0037] (2) Use 0.01M silver nitrate and 0.2M citric acid as the electrolyte, and the current density is 2mA / cm 2 , the deposition time is 180s, rinse with deionized water and dry naturally;

[0038] (3) Transfer the above-mentioned silver dendrite substrate to the ALD reaction chamber, and deposit a 10-cycle (~1.7 nm) zinc oxide film to form a zinc oxide-wrapped silver dendrite structure. The parameters for ALD deposition of zinc oxide are:

[0039] Reaction chamber temperature: 80 o C;

[0040] Reaction source: Deposit zinc oxide using diethyl zinc and H 2 O, diethylzinc and H 2 O is room temperature;

[0041] Pulse and cleaning time: the pulse of the metal source and the water source is 2 s; after each metal source...

Embodiment 3

[0046] A method for preparing a surface-enhanced Raman substrate with high stability and high Raman intensity, comprising the following steps:

[0047] (1) Ultrasonic clean the ITO glass with acetone, isopropanol, ethanol and deionized water for 5 minutes;

[0048] (2) Use 0.01M silver nitrate and 0.2M citric acid as the electrolyte, and the current density is 2mA / cm 2 , the deposition time is 180s, rinse with deionized water and dry naturally;

[0049] (3) Transfer the above-mentioned silver dendrite substrate to the ALD reaction chamber, and deposit a 20-cycle (~3.4 nm) zinc oxide film to form a zinc oxide-wrapped silver dendrite structure. The parameters for ALD deposition of zinc oxide are:

[0050] Reaction chamber temperature: 80 o C;

[0051] Reaction source: Deposit zinc oxide using diethyl zinc and H 2 O, diethylzinc and H 2 O is room temperature;

[0052] Pulse and cleaning time: the pulse of the metal source and the water source is 2 s; after each metal source...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com