Nanomaterial for negative electrode protection layer, negative electrode protection slurry, lithium negative electrode and lithium battery

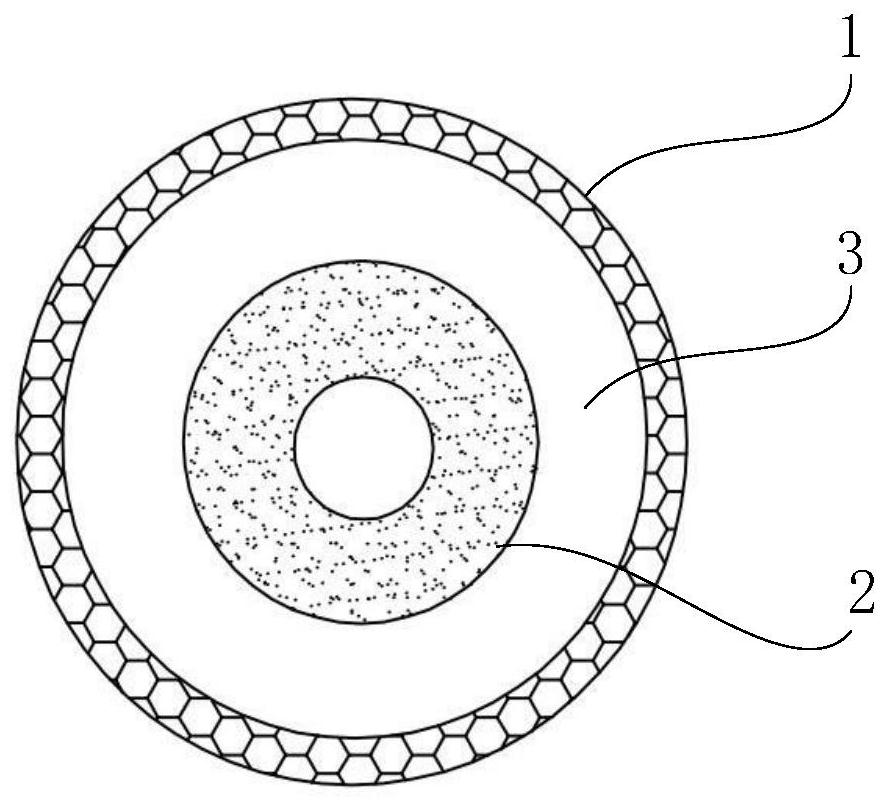

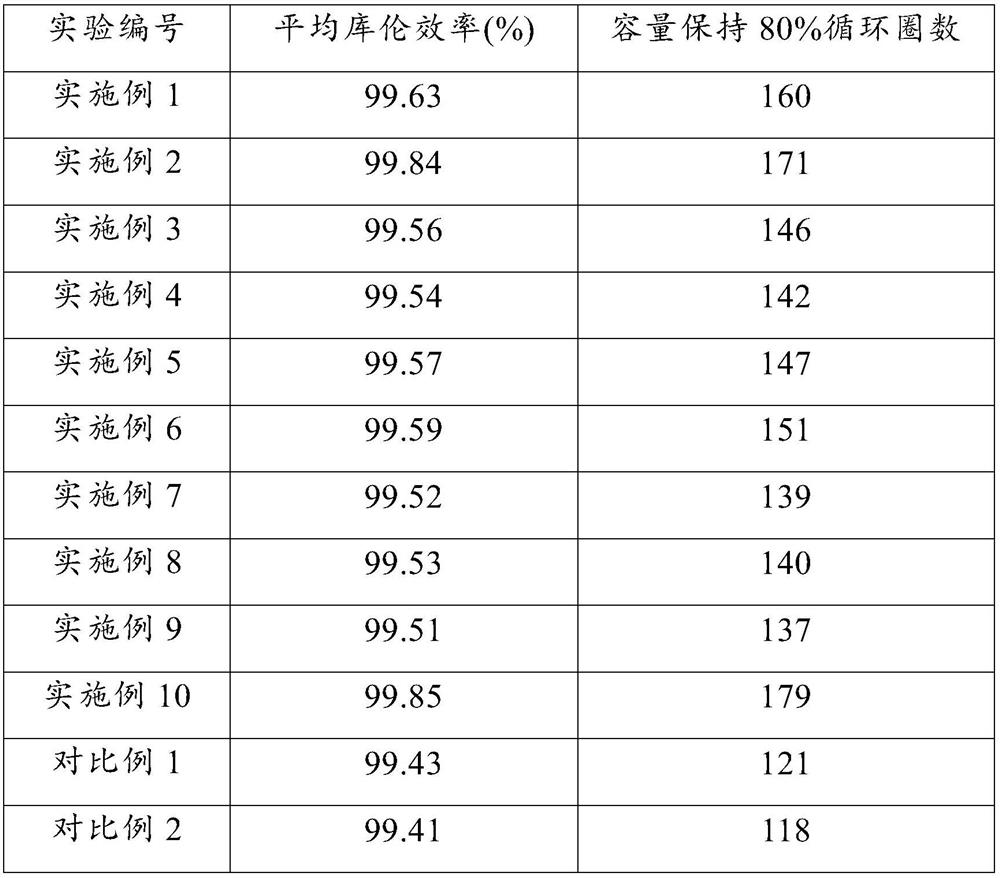

A technology of nanomaterials and protective layers, applied in nanotechnology for materials and surface science, lithium batteries, nanotechnology, etc., can solve problems such as uneven deposition of lithium on lithium anodes, improve lithium affinity, and relieve lithium branches. The generation of crystals and the uniform effect of lithium deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

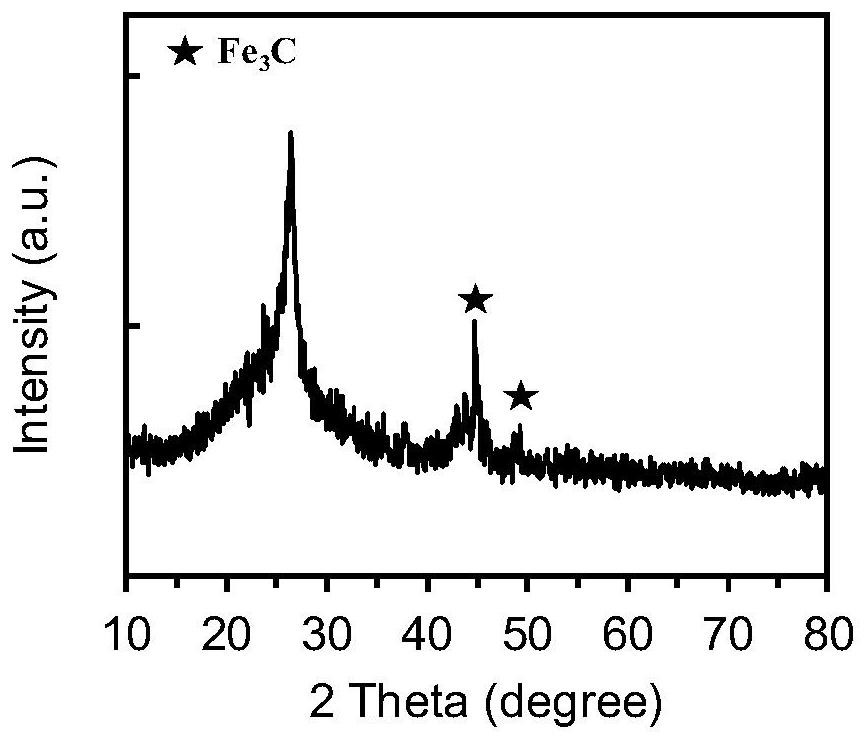

[0078] (1) Preparation of nanomaterials

[0079] ① Preparation of iron-containing precursor:

[0080] 116mg FeCl 3 ·6H 2 O and 270mg terephthalic acid were added in 5mL dimethylformamide (DMF) to form a mixed solution, wherein 0.8mol sodium hydroxide was contained in the dimethylformamide;

[0081] Transfer the mixed solution to a reaction kettle and heat it up to 100°C at a heating rate of 5°C / min, and keep the reaction at this temperature for 12 hours, then vacuum dry to obtain the crude product;

[0082] Wash the crude product several times with ethanol, then disperse the crude product in ethanol, maintain it at 70°C for 3 hours, and dry it in vacuum to obtain the crude product, which is the iron-containing precursor;

[0083] ②Add 1.5g of ultrasonically dispersed graphene and 1.5g of the prepared precursor into 30mL of deionized water, stir and react for 24 hours, and then remove the solvent by rotary evaporation to obtain powder;

[0084] ③The powder obtained in step ...

Embodiment 2

[0092] The lithium battery was prepared according to the method of Example 1, except that the preparation process of the nanomaterials was different so that the thickness of the carbon layer shell of the nanomaterials, the size of the outer diameter of the core and the size of the inner diameter of the inner core were different.

[0093] The preparation of nanomaterials in this embodiment is as follows:

[0094] ① Preparation of iron-containing precursor:

[0095] 120mg FeCl 3 ·6H 2 O and 250mg terephthalic acid are added in 5mL dimethylformamide (DMF) to form a mixed solution, wherein, 0.8mol sodium hydroxide is contained in the dimethylformamide;

[0096] Transfer the mixed solution to a reaction kettle and heat it up to 100°C at a heating rate of 5°C / min, and keep the reaction at this temperature for 12 hours, then vacuum dry to obtain the crude product;

[0097] Wash the crude product several times with ethanol, then disperse the crude product in ethanol, maintain it at...

Embodiment 3

[0102] Lithium batteries were prepared according to the method of Example 1, the difference being that the preparation process of the nanomaterials was different so that the thickness of the carbon layer shell of the nanomaterials was different:

[0103] The preparation of the nanomaterial is as follows:

[0104] Similar to the preparation method of nanomaterials in Example 1, the amount of graphene and iron-containing precursors in step ② is set to 2.5g and 1.5g, and the final product is collected after the reaction. After identification, the carbon layer shell of the resulting nanomaterials It consists of 5-7 carbon layers, the thickness of the carbon layer shell is 12nm, the outer diameter of the inner core is 45nm, and the inner diameter of the inner core is 5.4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com