Super-hybrid composite material battery box and preparation method thereof

A composite material and battery box technology, used in the isolation of batteries from their environment, battery pack components, circuits, etc., can solve problems such as poor surface finish, long molding cycle, and inability to achieve high strength and stiffness Bond strength, easy forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A method for preparing the battery box of the described hyper-hybrid composite material, comprising the following steps:

[0043] S1, respectively stamping two metal plates to form an inner metal shell 1 and an outer metal shell 3;

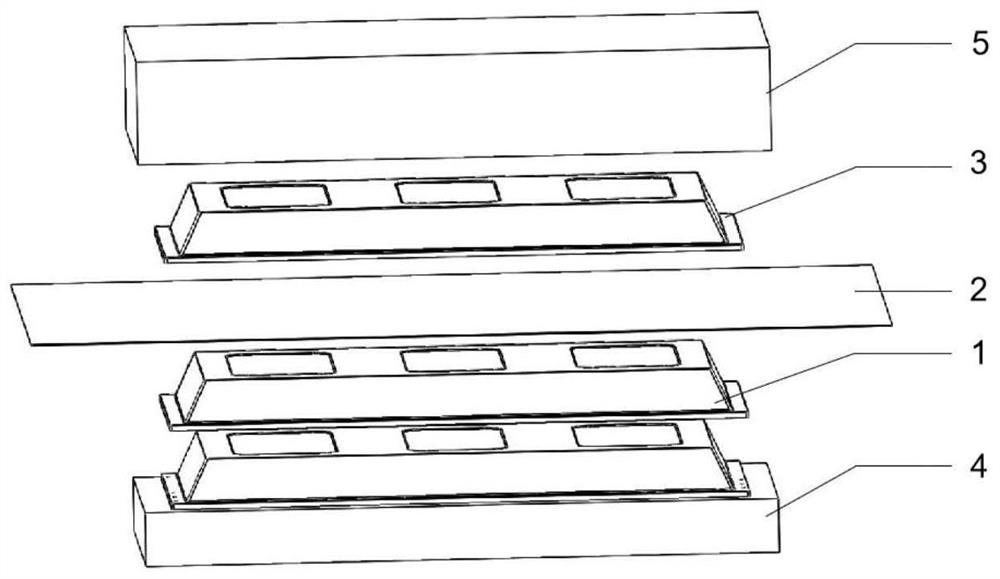

[0044] S2, put the inner metal shell 1 on the lower mold 4, then lay the sheet molding compound 2 on the inner metal shell 1, and then put the outer metal shell 3 on the top of the sheet molding compound 2, so that the outer metal The shells 3 are aligned with the centers of the upper molds 5, respectively.

[0045] S3, turn on the press, make the upper mold 5 close the lower mold 4 under the preset pressure, and then turn on the heating device to heat the upper mold 5 and the lower mold 6 at a preset temperature for a preset time;

[0046] S4, open the upper mold 5 and the lower mold 4, take out the formed battery box blank shell, and obtain a battery box made of a hyper-hybrid composite material after cleaning.

[0047] Wherein, in S2 ,...

Embodiment 1

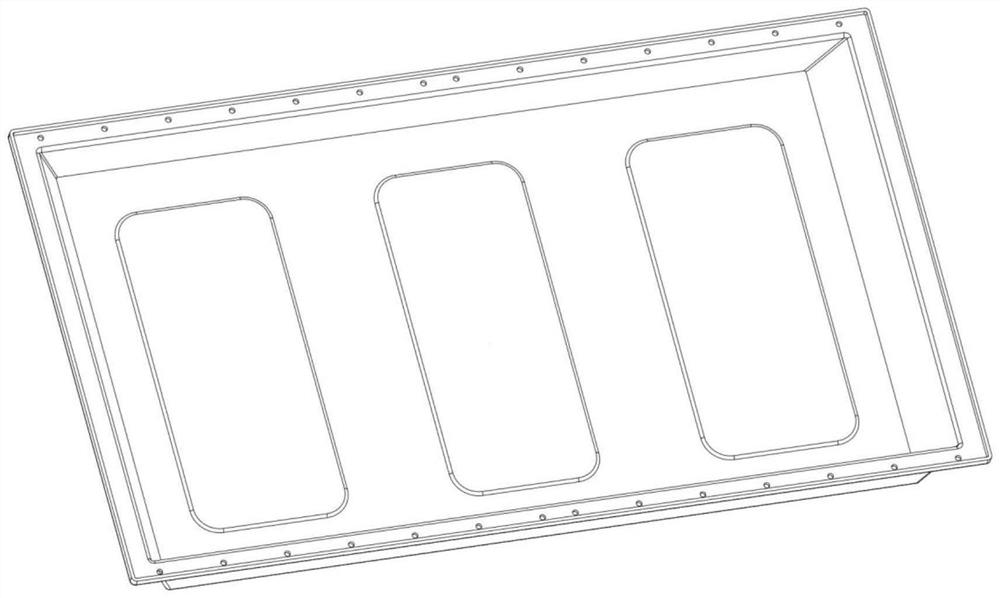

[0052] Such as figure 1 As shown, a battery box made of ultra-hybrid composite materials includes an inner metal shell 1, an outer metal shell 3 and a sheet molding compound 2, the inner metal shell 1 is sleeved in the outer metal shell 3, The sheet molding compound 2 is connected between the inner metal shell 1 and the outer metal shell 3 .

[0053] The inner metal shell 1 and the outer metal shell 3 are made of 6061 aluminum alloy plates, and the outer surface of the inner metal shell 1 and the inner surface of the outer metal shell 3 are respectively sandblasted. The thicknesses of the inner metal shell 1 and the outer metal shell 3 are respectively 0.2 mm, and the thickness of the battery box made of super-hybrid composite material is 2 mm.

[0054] Wherein, the sheet molding compound 2 is an unsaturated polyester sheet molding compound available on the market, and the two sides of the sheet molding compound 2 are respectively impregnated with the inner metal shell 1 and ...

Embodiment 2

[0062] On the basis of Example 1, other conditions remain unchanged, and the inner metal shell 1 is replaced with 0.2mm thick B340LA cold-rolled steel plate, then the following effects can be achieved:

[0063] By measuring the thickness, the thickness of the formed battery box is 2mm, and the overall weight is 4.3kg. Compared with the aluminum alloy battery box of the same thickness, the weight is reduced by 12%; compared with the steel battery box of the same thickness, the weight is reduced by 69%. . At the same time, using the standard test of GB / T 2048-2008 "Determination of Plastic Combustion Performance by Horizontal and Vertical Methods", the vertical combustion level of this structure is V0 level, and the horizontal combustion level is HB level. Since the exterior is made of steel, it can be painted by electrophoresis and has the function of electromagnetic shielding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com