High-flux and high-selectivity acid-resistant nanofiltration membrane based on special base and preparation method of acid-resistant nanofiltration membrane

A high-selectivity, high-throughput technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as non-selective defects, general acid resistance of nanofiltration membranes, and complex synthesis of nanomaterials. Achieve the effects of improving water flux, simplifying the interfacial polymerization process, and making the synthesis process simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

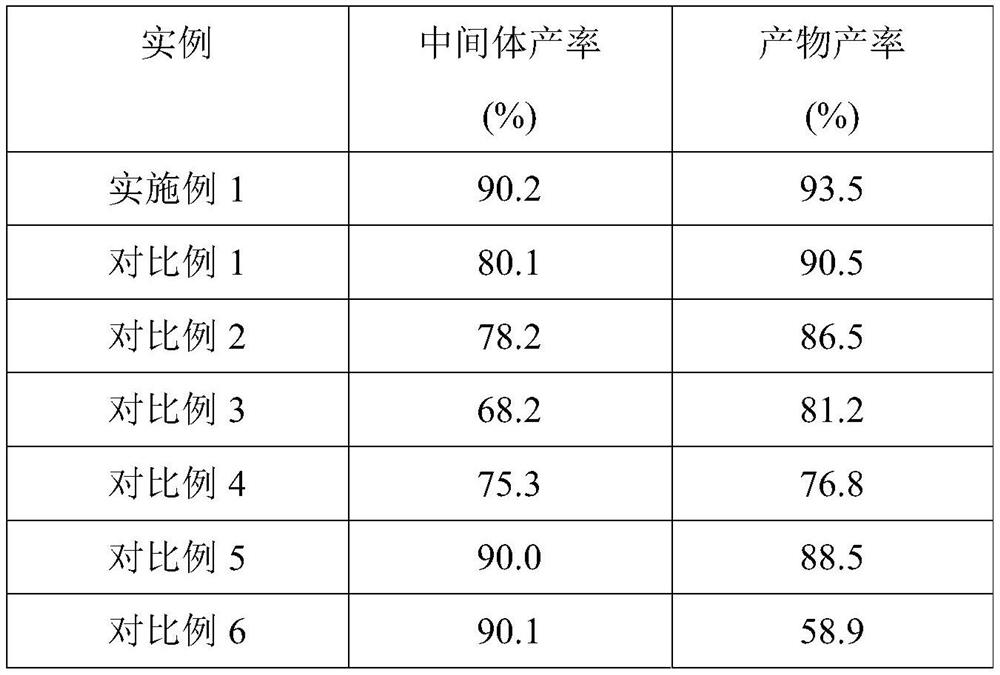

Embodiment 1

[0024] ①, the preparation of intermediates

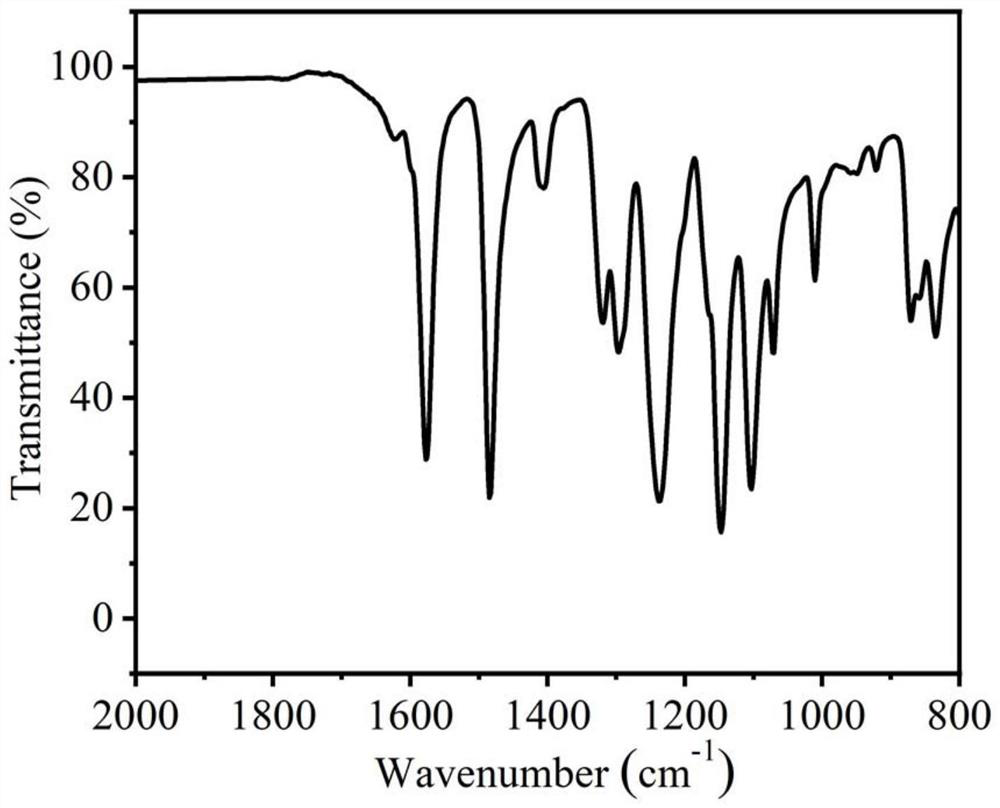

[0025] Under the condition of ice bath, dissolve 18g of 2-methyl-4-nitroaniline monomer into 240mL of trifluoroacetic acid, stir to make it fully dissolved; then add 7.47g of aldehyde-based monomer into the above solution, Mix well, and react at 25° C. for 48 hours to obtain a brown liquid, and the whole reaction is carried out under nitrogen. The resulting liquid was slowly added to 300 mL of deionized water with continuous stirring. Then 6 mol / L sodium hydroxide was added dropwise to adjust the pH to 9, and vacuum filtration was used to obtain the Telleg base nitro monomer with a rigid twisted structure.

[0026] ②. Preparation of Teleg base amine monomer

[0027] Under nitrogen, take 10 g of the intermediate obtained in the above step ① and disperse it in 200 mL of absolute ethanol, then add 1 g of palladium / carbon as a catalyst and heat to reflux. 60 mL of hydrazine hydrate was added dropwise to the reaction solution, and the...

Embodiment 2

[0042] Embodiment 2: Change the 2-methyl-4-nitroaniline monomer in embodiment 1 into 2-methyl-3-nitroaniline monomer, and other operations are the same

[0043] Example 1, a Telleg base amine monomer with a rigid and twisted structure was prepared.

Embodiment 3

[0044] Example 3: Change the 2-methyl-4-nitroaniline monomer in Example 1 to 4-nitroaniline monomer, other operations are the same as in Example 1, and a Teller with a rigid and twisted structure is prepared Lattice base amine monomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com