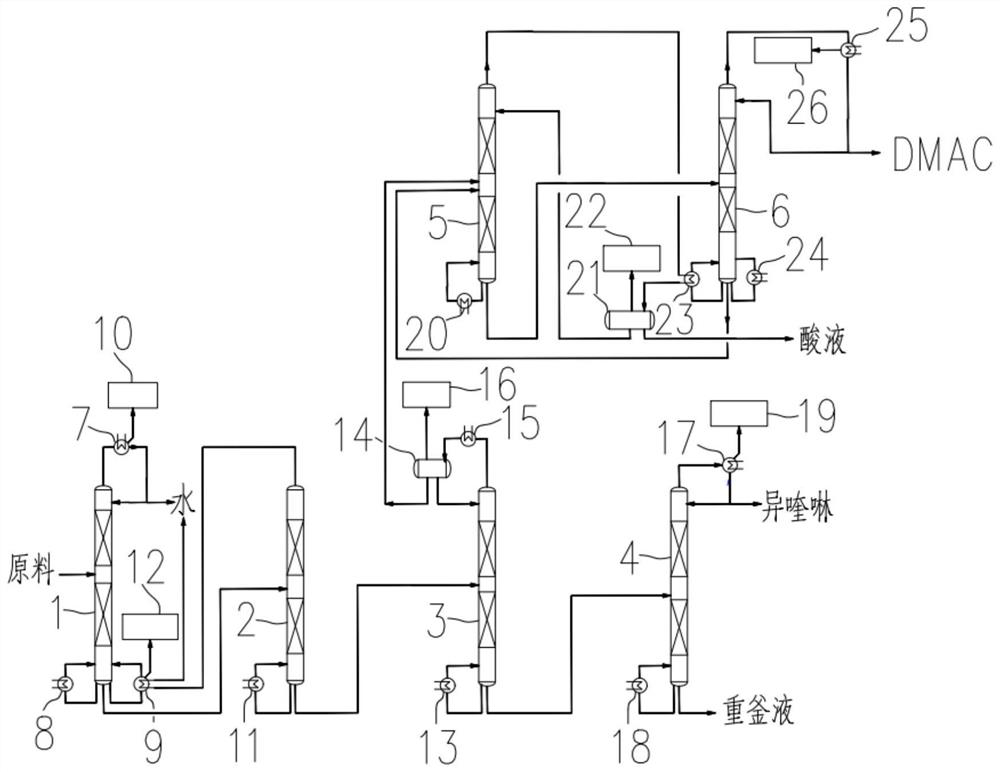

Method and device for recovering DMAC (dimethylacetamide) and isoquinoline from solution

A technology of isoquinoline and solution, which is applied in the field of recycling DMAC and isoquinoline, can solve the problems of difficult handling of reaction solids, greenhouse gas emissions, complicated separation process, etc., and achieves the effects of easy industrial application, reduced emissions, and simple method flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Pump the mixed solution raw materials into the middle part of the first-effect dehydration tower (1), the total feed amount is 3093.93kg / h, including DMAC857.66kg / h, isoquinoline 53.59kg / h, water 1903.75kg / h, heavy components 4.51kg / h, tower top pressure 13kpa(A), operating temperature 51.2°C, gas phase water under reduced pressure is obtained at the top of the tower, and liquid phase water is obtained by condensation with a condenser and refrigerant, and the water is divided into two parts, 33%wt pump reflux To the top of the tower, 67% wt is extracted and recovered outside the system, and the output flow rate is 1906.29kg / h; the concentrated mixed solution of isoquinoline, acetic acid, DMAC, water, and heavy components is obtained from the tower reactor, which is pumped into the second-effect dehydration tower (2);

[0043] (2) The mixed liquid from the tank of the first-effect dehydration tower (1) enters the top of the second-effect dehydration tower (2), the pr...

Embodiment 2

[0050] In the step (4), the isoquinoline refining tower (4) tower top pressure 1.5kpa (A), 104 ℃ of operating temperatures; In the step (5), the acetic acid tower (5) operating temperature 158 ℃; In the step (6), the DMAC tower ( 6) The operating temperature is 82° C., and the other steps are the same as in Example 1.

[0051] The obtained isoquinoline product mass fraction is 99.89%, and the DMAC product mass fraction is 99.93%.

Embodiment 3

[0053] Isoquinoline refining tower (4) tower top pressure 1.9kpa (A) in step (4), 107 ℃ of operating temperatures; 160 ℃ of acetic acid tower (5) operating temperatures in step (5); DMAC tower ( 6) The operating temperature is 87° C., and the other steps are the same as in Example 1.

[0054] The obtained isoquinoline product mass fraction is 99.66%, and the DMAC product mass fraction is 99.81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com