Electrodialysis device and method for separating nitric acid and acetic acid

An electrodialysis, nitric acid technology, applied in electrodialysis, chemical instruments and methods, nitric acid and other directions, can solve the problems of low distribution coefficient and separation factor, complicated evaporation operation process, low separation efficiency, etc., to improve the purity and nitric acid recovery. efficiency, reducing energy consumption, and the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

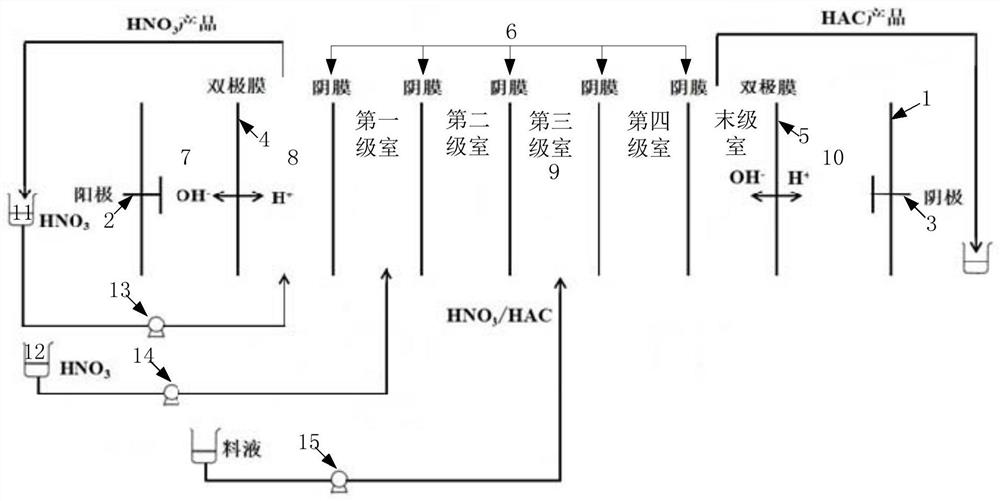

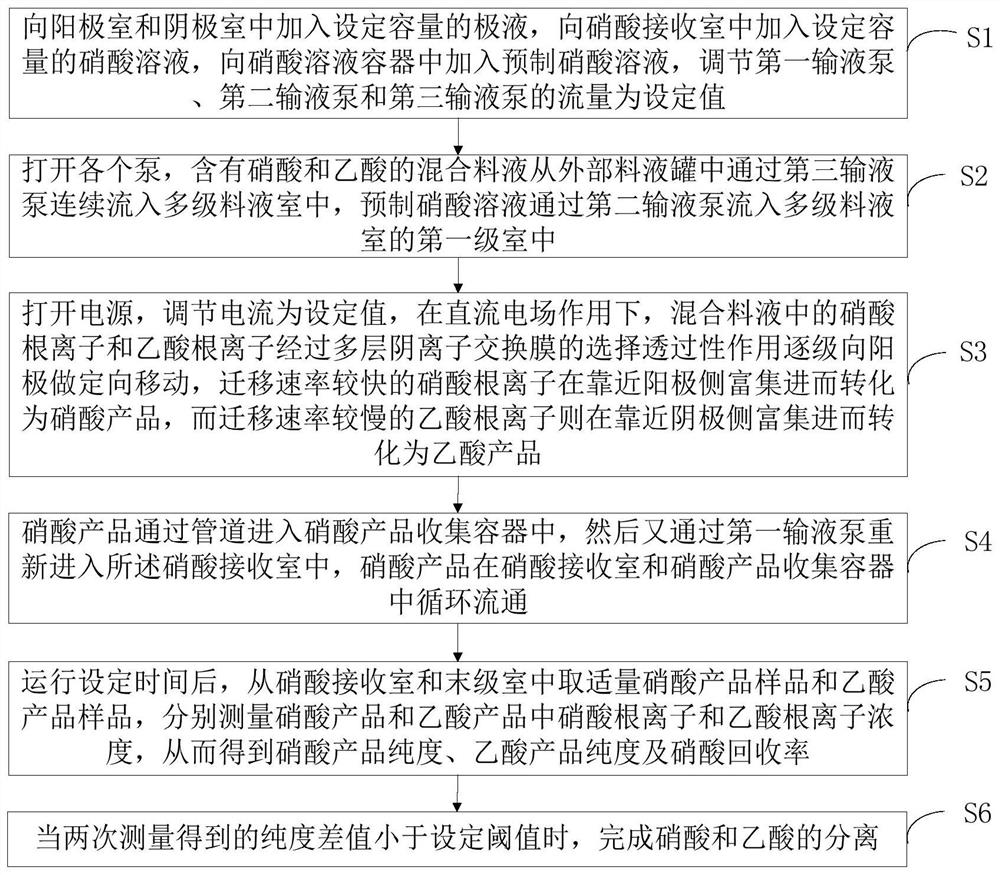

Method used

Image

Examples

Embodiment 1

[0052] A sodium nitrate solution with an initial concentration of 0.5 mol / L was introduced into the anode compartment and the cathode compartment. The initial feed liquid is the mixed solution of 0.93mol / L nitric acid and 0.12mol / L acetic acid, the concentration of the nitric acid reflux liquid is 0.1mol / L, and the flow rate of the nitric acid reflux liquid is 0.5ml / min. At the beginning, a small amount of nitric acid (( The concentration is 0.1mol / L), the current is set to 1.2A, and the nitric acid product purity is 99.88%, the acetic acid product liquid purity is 64.19%, and the nitric acid recovery rate is 97.48% after energizing for 45 minutes.

Embodiment 2

[0054] A sodium nitrate solution with an initial concentration of 0.5 mol / L was introduced into the anode compartment and the cathode compartment. The initial feed liquid is the mixed solution of 0.93mol / L nitric acid and 0.12mol / L acetic acid, the concentration of the nitric acid reflux liquid is 0.5mol / L, and the flow rate of the nitric acid reflux liquid is 0.5ml / min. At the beginning, a small amount of nitric acid (( The concentration is 0.1mol / L), the current is set to 1.2A, and the nitric acid product purity is 99.89%, the acetic acid product liquid purity is 70.34%, and the nitric acid recovery rate is 97.33% after energizing for 40 minutes.

[0055] The electrodialysis device and method for separating nitric acid and acetic acid provided by the present invention utilizes the difference in ionization degree of nitric acid and acetic acid in aqueous solution and the difference in ion migration speed under an external electric field to separate nitric acid / acetic acid. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com