Method for chemical reaction of mixture in supercritical state and application thereof

A technology of chemical reaction and mixture, applied in the field of chemical reaction, can solve problems such as increasing costs, and achieve high thermal efficiency and scientific and reliable principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

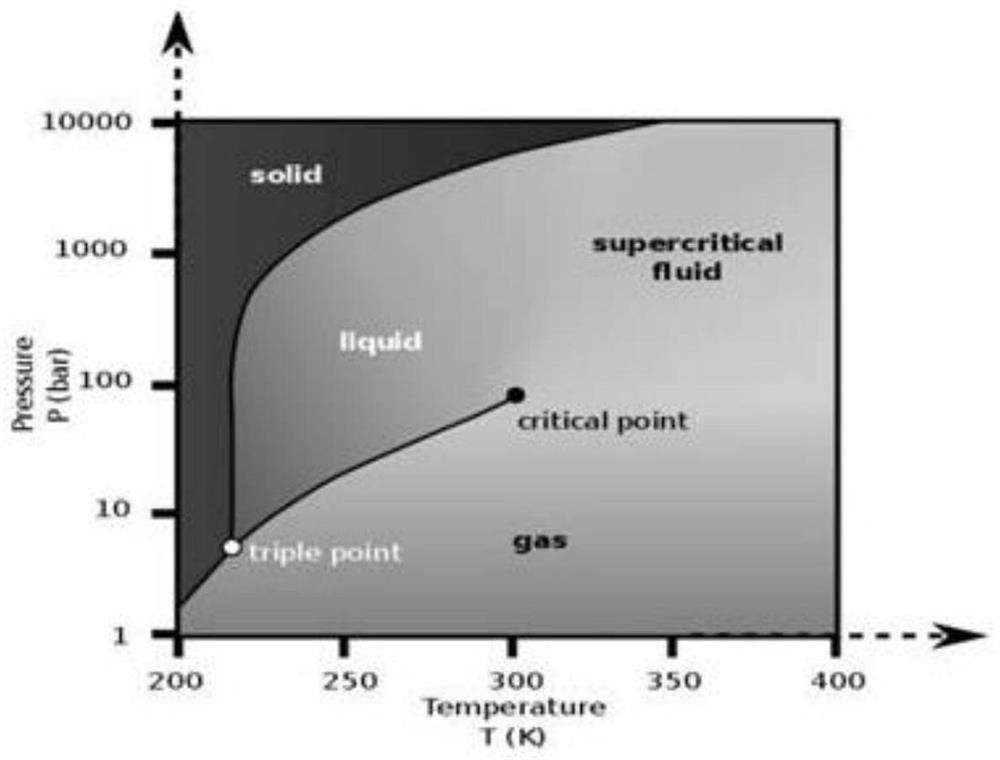

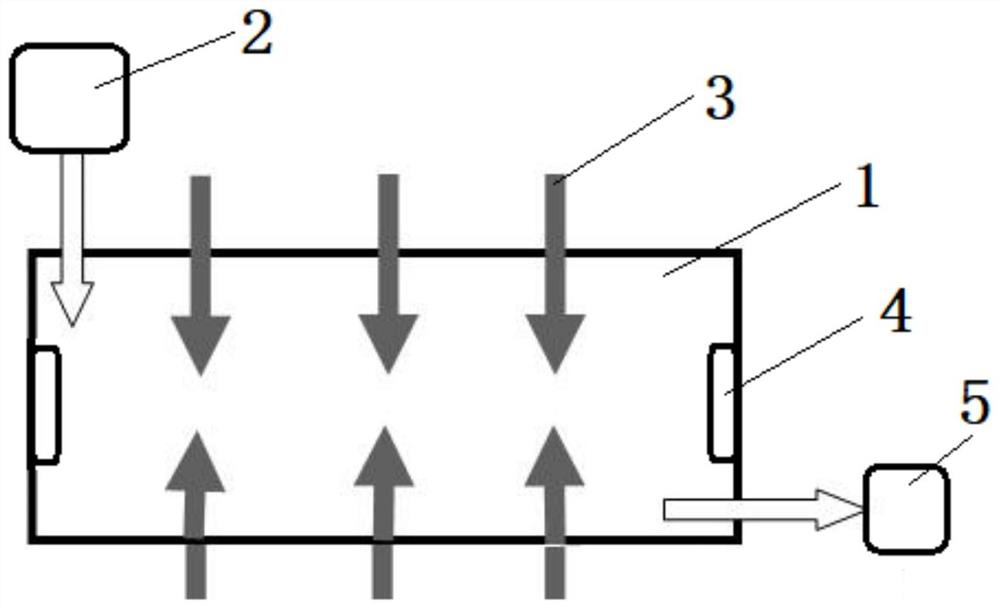

[0035] The specific technological process that the method that the mixture involved in the present embodiment chemically reacts in the supercritical state carries out the cracking treatment to the heavy oil is as follows:

[0036] First, the heavy oil (semi-solid pitch) and water are mechanically mixed by the raw material input system 2 according to the volume ratio of 1:1.6 to form a suspension fluid mixture and injected into the reaction vessel 1;

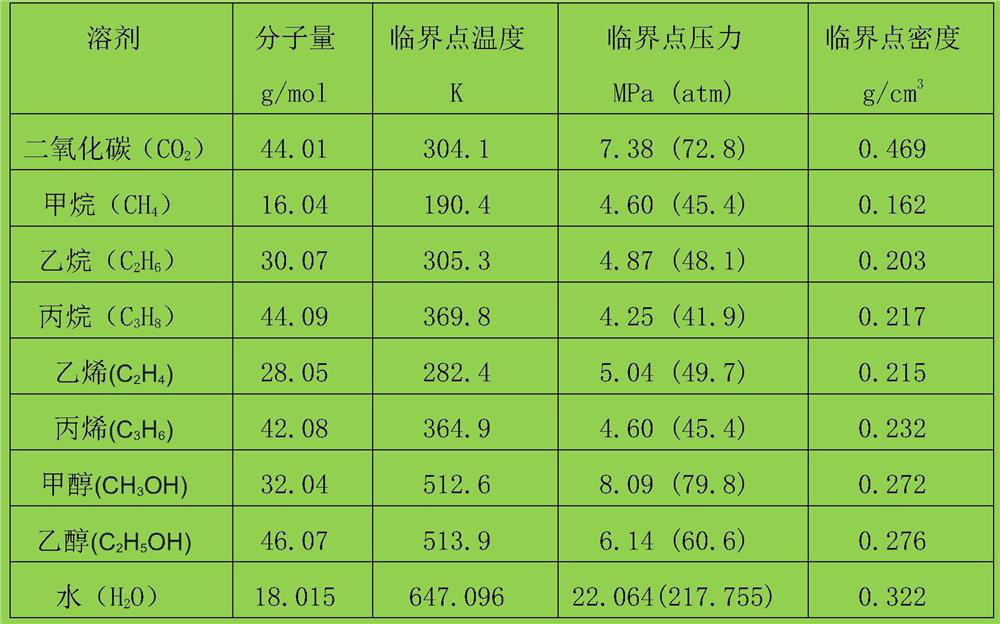

[0037] Then, start the electrode system 3 pre-placed in the reaction vessel 1 to heat and pressurize the fluid mixture. The electrode system 3 includes 5 electrodes, which are arranged in a circle and discharge in sequence. The discharge interval between adjacent electrodes is 2 seconds, and each discharge is 80 milliseconds, until the monitoring system 4 monitors that the fluid mixture reaches a supercritical state, and the heavy oil and water molecules are fully mixed;

[0038] Finally, after the fluid mixture reaches the super...

Embodiment 2

[0041] The specific technological process that the mixture involved in the present embodiment is chemically reacted in a supercritical state to separate and crack the oil sand is as follows:

[0042] First, the oil sand (heavy oil-attached sand) and water are mechanically mixed by the raw material input system 2 according to the volume ratio of 1:1 to form a fluid mixture, and injected into the reaction vessel 1;

[0043] Then, start the electrode system 3 pre-placed in the reaction vessel 1 to heat and pressurize the fluid mixture to reach the supercritical point of water, shake the reaction vessel 1 to make the supercritical water fully dissolve the heavy oil attached to the sand, and obtain a supercritical fluid mixture;

[0044] Finally, start all electrodes to discharge 100 milliseconds every 5 seconds at the same time, triggering the chemical reaction of the supercritical fluid mixture, cracking all heavy oils to obtain reaction products, including gasoline and naphtha (...

Embodiment 3

[0046] The method that the mixture involved in this embodiment chemically reacts in a supercritical state cleans the coal to make carbon and cracks the coal tar. The specific process is as follows:

[0047] First, the pulverized coal and water are mechanically mixed through the raw material input system 2 according to the volume ratio of 1:1.3 to form a fluid mixture, and injected into the reaction vessel 1;

[0048] Then, start the electrode system 3 pre-placed in the reaction vessel 1 to heat and pressurize the fluid mixture to reach the supercritical point of water, shake the reaction vessel 1 to make the supercritical water fully dissolve the coal tar attached to the coal, and obtain supercritical fluid mixture;

[0049] Finally, start all electrodes to discharge for 1 second every 5 seconds at the same time to initiate a chemical reaction of the supercritical fluid mixture to crack all coal tar to obtain reaction products including naphtha and solid carbon, which are disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com