Preparation process and device of sodium diacetate food additive without side effects

A technology of food additive and sodium diacetate, which is applied in the direction of carboxylate preparation, carboxylate preparation, control/adjustment process, etc., can solve the inconvenient and inconvenient production work that cannot realize feeding, mixing, drying, and unfavorable industrialization Large-scale cyclone centrifugal drying work and other problems achieve the effect of convenient mixing and stirring work, good production and processing work, and good mixed production work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

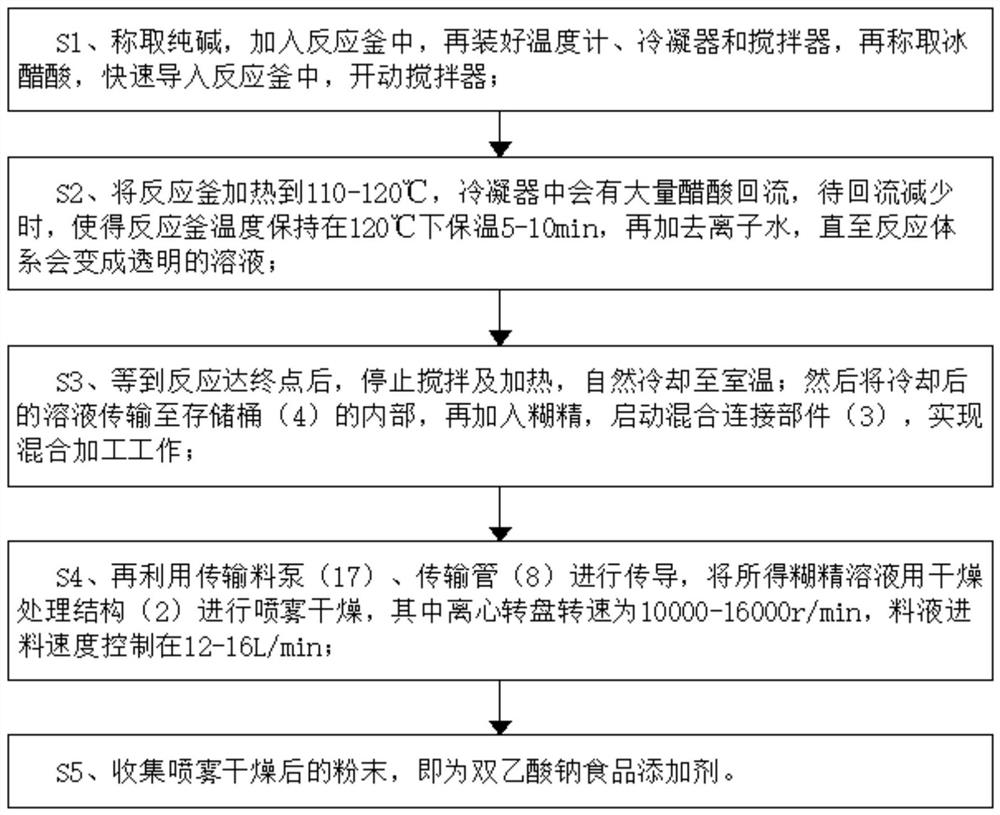

[0057] A sodium diacetate food additive without side effects, see figure 1 , its preparation process comprises the following steps:

[0058] S1. Weigh soda ash, add it into the reaction kettle, then install the thermometer, condenser and agitator, then weigh glacial acetic acid, quickly introduce it into the reaction kettle, and start the agitator;

[0059] S2. Heat the reaction kettle to 110°C, and there will be a large amount of acetic acid refluxing in the condenser. When the reflux is reduced, keep the temperature of the reaction kettle at 120°C for 5 minutes, and add deionized water until the reaction system becomes transparent. solution;

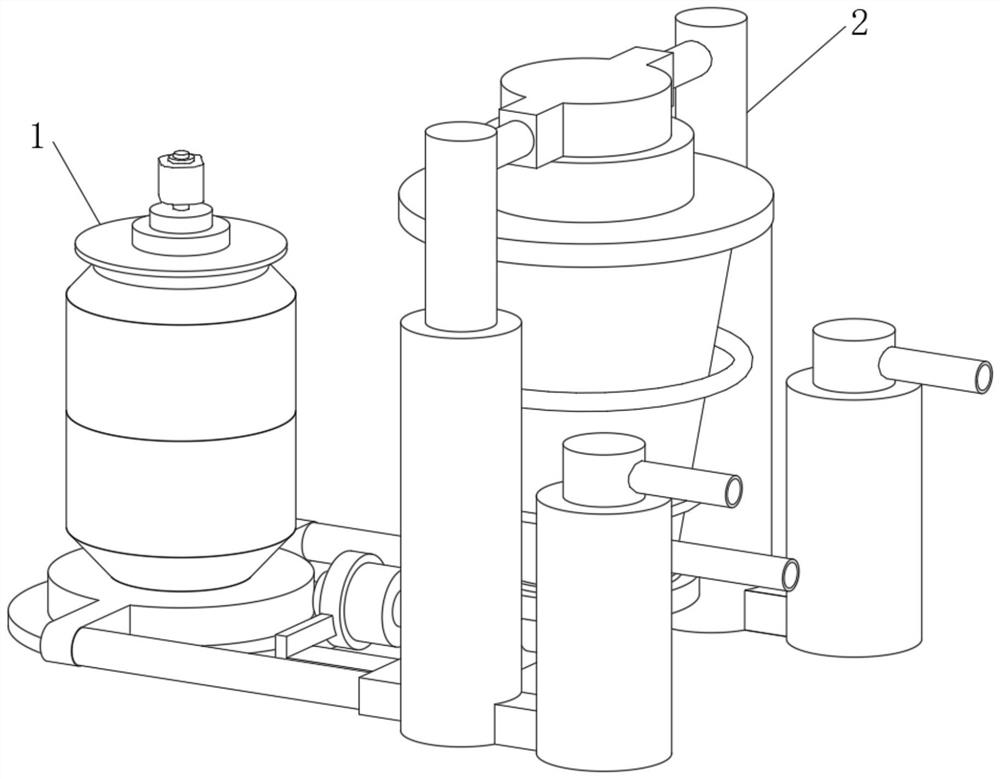

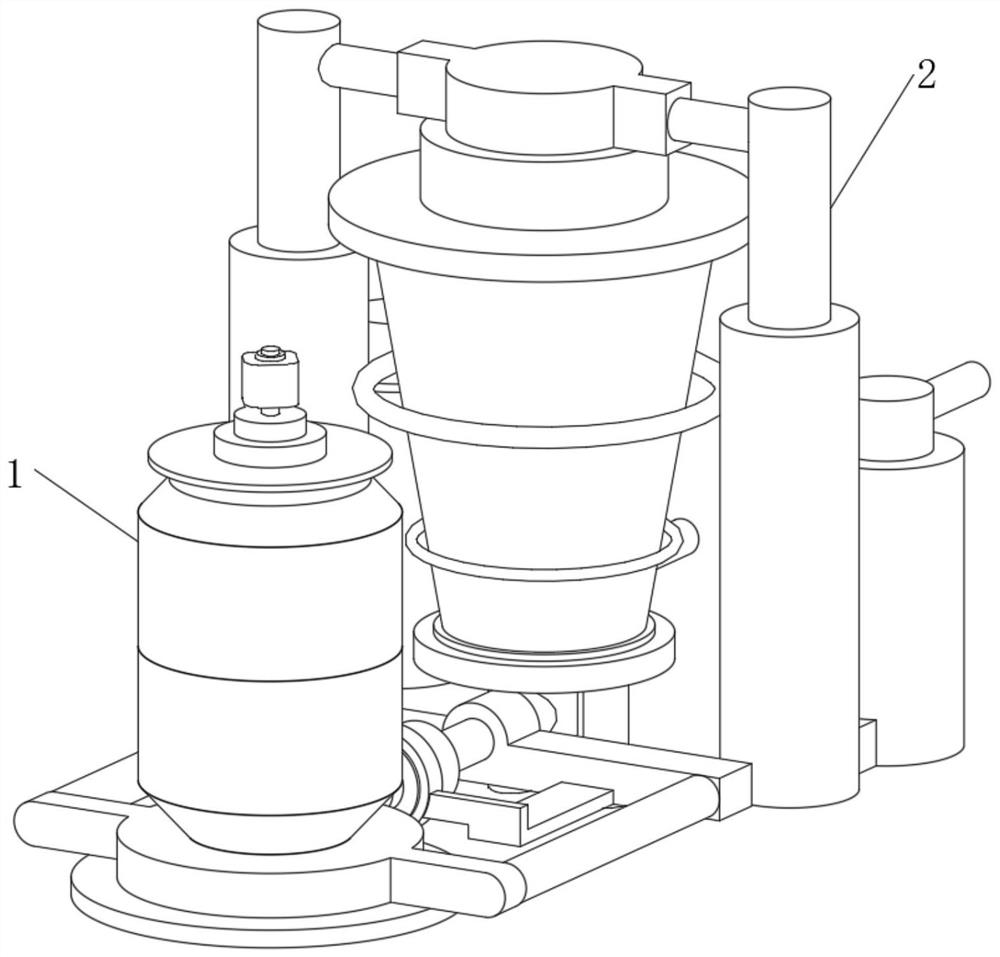

[0060] S3. After the reaction reaches the end point, stop stirring and heating, and naturally cool to room temperature; then transfer the cooled solution to the interior of the storage barrel, add dextrin, start the mixing and connecting parts, and realize the mixing and processing work;

[0061] S4, using the transmission material p...

Embodiment 2

[0065] A sodium diacetate food additive without side effects, see figure 1 , its preparation process comprises the following steps:

[0066] S1. Weigh soda ash, add it into the reaction kettle, then install the thermometer, condenser and agitator, then weigh glacial acetic acid, quickly introduce it into the reaction kettle, and start the agitator;

[0067] S2. Heat the reaction kettle to 115°C, and there will be a large amount of acetic acid refluxing in the condenser. When the reflux is reduced, keep the temperature of the reaction kettle at 120°C for 8 minutes, and add deionized water until the reaction system becomes transparent. solution;

[0068] S3. After the reaction reaches the end point, stop stirring and heating, and naturally cool to room temperature; then transfer the cooled solution to the interior of the storage barrel, add dextrin, start the mixing and connecting parts, and realize the mixing and processing work;

[0069] S4, using the transmission material p...

Embodiment 3

[0073] A sodium diacetate food additive without side effects, see figure 1 , its preparation process comprises the following steps:

[0074] S1. Weigh soda ash, add it into the reaction kettle, then install the thermometer, condenser and agitator, then weigh glacial acetic acid, quickly introduce it into the reaction kettle, and start the agitator;

[0075] S2. Heat the reaction kettle to 117°C, and there will be a large amount of acetic acid refluxing in the condenser. When the reflux is reduced, keep the temperature of the reaction kettle at 120°C for 10 minutes, and add deionized water until the reaction system becomes transparent. solution;

[0076] S3. After the reaction reaches the end point, stop stirring and heating, and naturally cool to room temperature; then transfer the cooled solution to the interior of the storage barrel, add dextrin, start the mixing and connecting parts, and realize the mixing and processing work;

[0077] S4, using the transmission material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com