Method for treating reverse osmosis concentrated water by using electrochemical water treatment device

A technology for reverse osmosis concentrated water and water treatment devices, which is applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., and can solve the problems of low filling density, large device footprint, and low filtration efficiency. , to achieve the effect of low packing density, large floor space and high packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The reverse osmosis concentrated water is treated by a coiled electrochemical water treatment device. The main salt ions in the reverse osmosis concentrated water are SO 4 2- (100mg·L -1 ), Cl - (350mg·L -1 ), Ca 2+ , Na + , Mg 2+ , K + and clonidazole (10 mg L -1 ) pollutants.

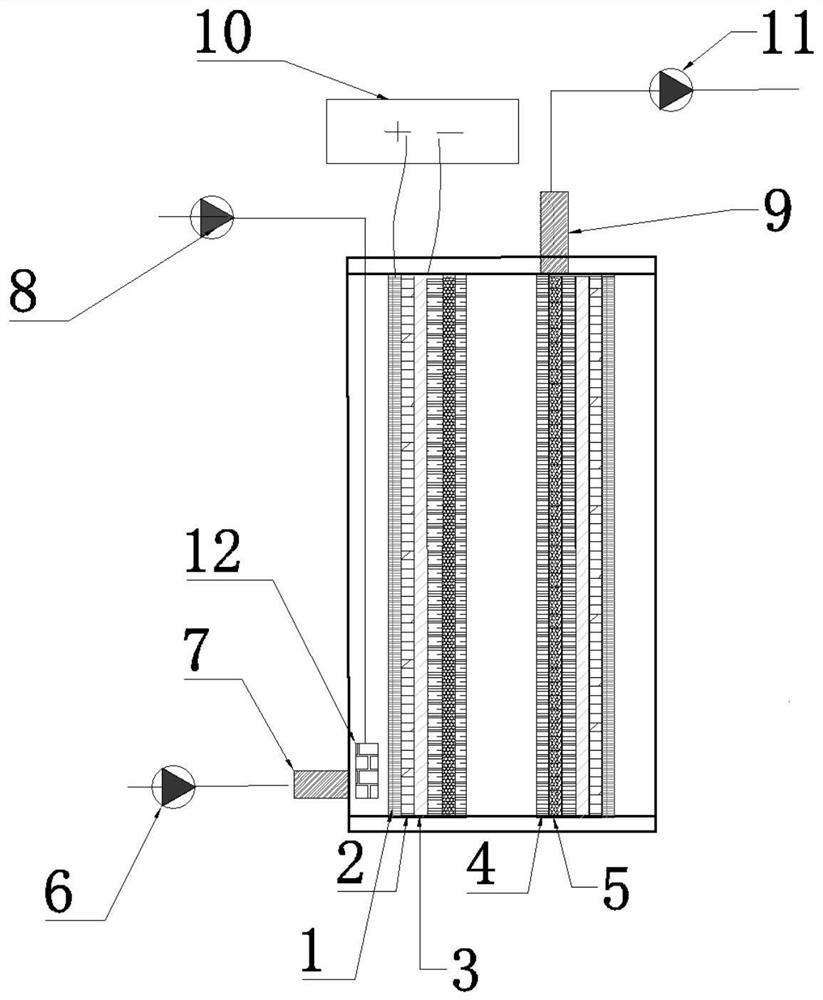

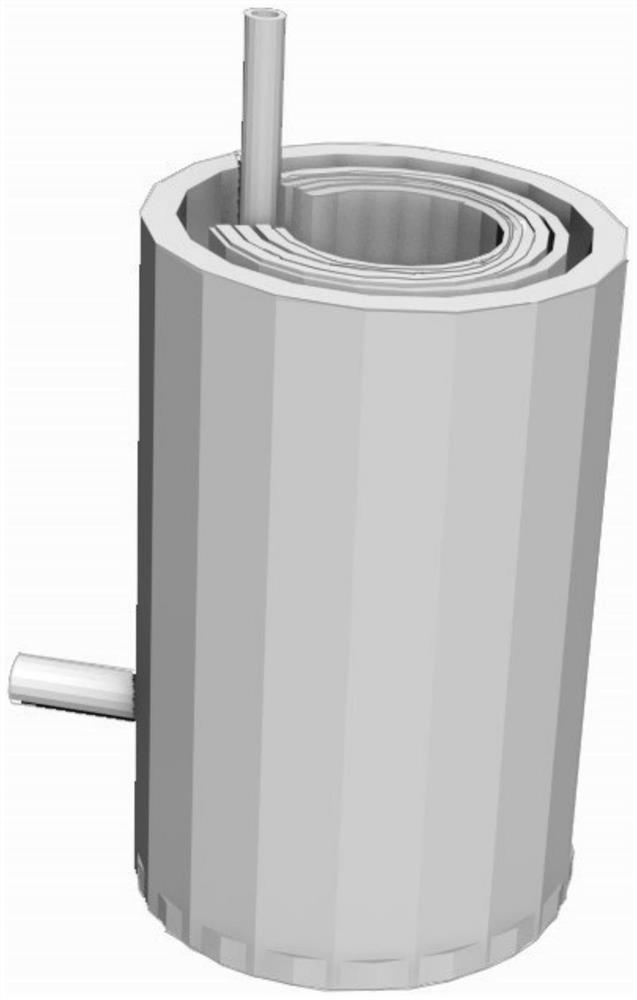

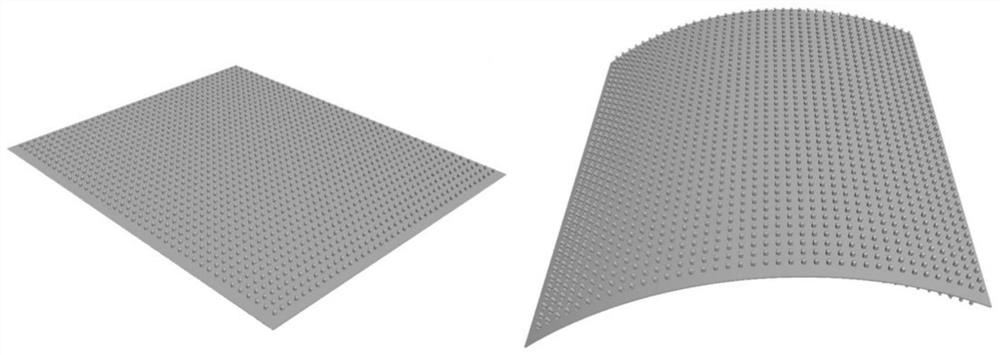

[0043] The wound-type electrochemical water treatment device is integrated with a conductive filter membrane and a heterogeneous Fenton-like system, and includes a reactor body and a wound-type membrane assembly. structure as figure 1 and figure 2 As shown, the device includes a cylindrical shell of 70×110 cm, a wound membrane module and an aeration device arranged in the cylindrical shell. The cross section of the wound membrane module is C-shaped, and includes an electrode mesh 1 , an insulating mesh 2 , a conductive filter membrane 3 , a flow channel spacer 5 and a diversion bag 4 . The electrode mesh 1 is the anode, and the positive electrode of the DC power supply 10 is extern...

Embodiment 2

[0054] Utilize the electrochemical water treatment device of Example 1 to treat the reverse osmosis concentrated water, and the main salt ions in the simulated reverse osmosis concentrated water are SO 4 2- (100mg·L -1 ), Cl - (350mg·L -1 ), Ca 2+ , Na + , Mg 2+ , K + and clonidazole (10 mg L -1 ) pollutants.

[0055] The difference between the processing steps and Example 1 is: the advanced oxidizing agent adopts sodium persulfate, 250ml of simulated reverse osmosis concentrated water is mixed with sodium persulfate solution, and the mixed sodium persulfate solution concentration is 10mmol L. -1 , Sodium persulfate catalyzes the generation of hydroxyl radicals, sulfate radicals, etc. on the carbon nanotube conductive filter membrane 3 loaded with cerium oxide, and oxidizes and degrades organic pollutants in reverse osmosis concentrated water. Then after two cycles, the removal efficiency of clonidazole in reverse osmosis concentrated water reaches 85%.

Embodiment 3

[0057] Utilize the electrochemical water treatment device of Example 1 to treat the reverse osmosis concentrated water, and the main salt ions in the simulated reverse osmosis concentrated water are SO 4 2- (250mg·L -1 ), Cl - (132mg·L -1 ), Ca 2+ , Na + , Mg 2+ , K + and clonidazole (10 mg L -1 ) pollutants.

[0058] The difference between the processing steps and Example 1 is: the advanced oxidizing agent adopts sodium hypochlorite, 250ml simulated reverse osmosis concentrated water mixes the sodium hypochlorite solution, and the mixed sodium hypochlorite solution concentration is 10mmol·L -1 . Then after two cycles, the removal efficiency of clonidazole in reverse osmosis concentrated water reached 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com